Gas-liquid two-phase carbon dioxide corrosion inhibitor and preparation method thereof

A carbon dioxide and corrosion inhibitor technology, applied in the direction of organic chemistry, can solve the problems of production safety hazards, pipeline gas phase protection, etc., and achieve the effect of low production process requirements, less addition, and easy practical application and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this example, the preparation of the gas-liquid two-phase carbon dioxide corrosion inhibitor is divided into two steps: the first step is the synthesis of the main agent 2,5-dihydro-3,5-dimethyl-2-isopropylthiazole , the second step is the preparation of corrosion inhibitor.

[0045] Pour 28% ammonia water into a three-necked flask, add isobutyraldehyde dropwise at a temperature of 35°C under stirring (about 3 to 4 hours), and react for 9 to 10 hours after the drop;

[0046] After cooling, the solution is poured into a separatory funnel and allowed to stand for stratification, and the upper organic phase is separated (this is an intermediate product with a molecular weight of 125);

[0047] Pour the intermediate product and sulfur into a three-necked flask, stir and heat, react at a constant temperature of 140°C for about 6 hours and then cool;

[0048] The cooled solution was distilled under reduced pressure at about 50 mmHg to collect fractions.

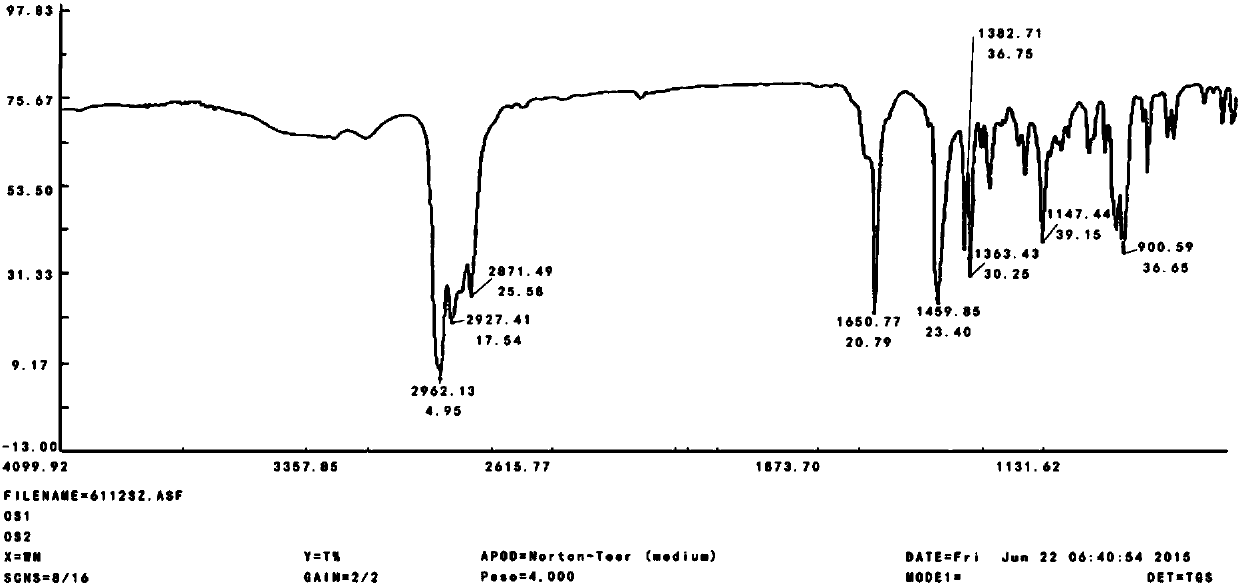

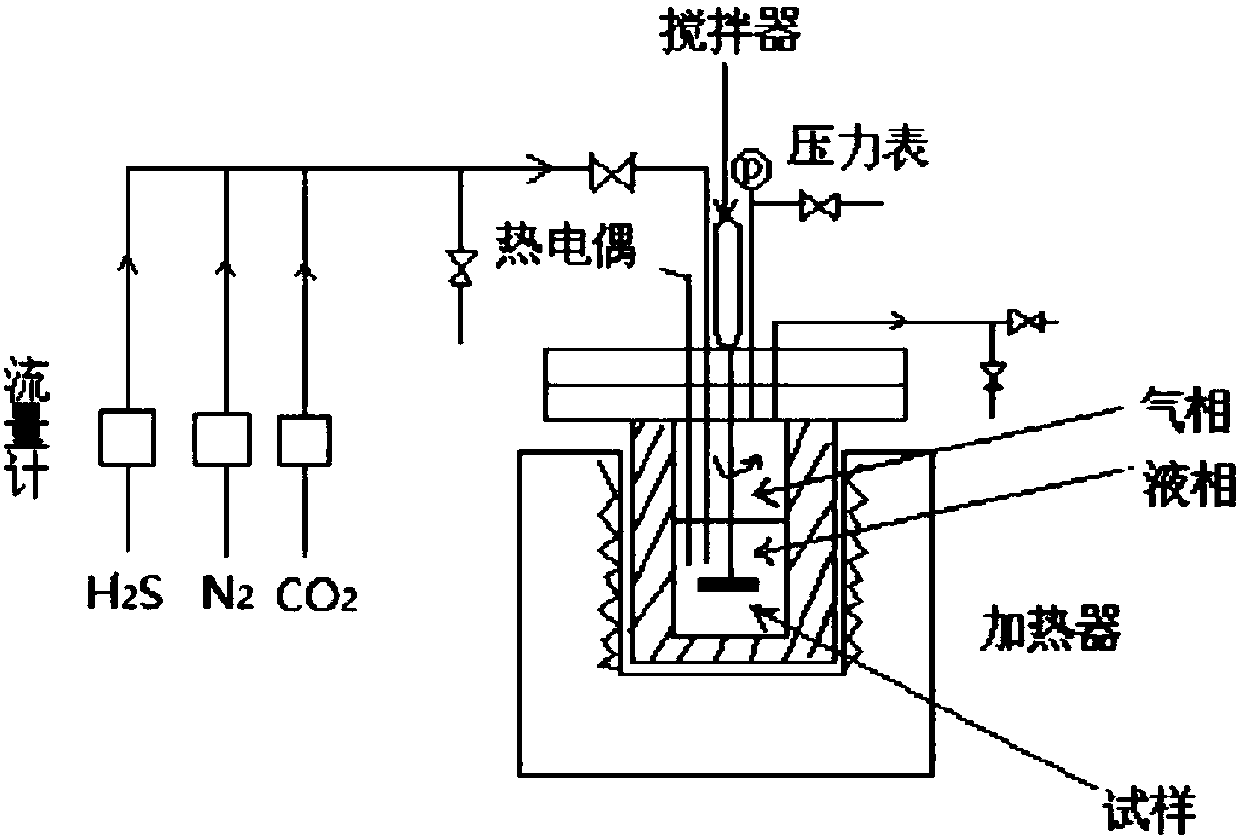

[0049] figure ...

Embodiment 2

[0065] 2,5-dihydro-3,5-dimethyl-2-isopropylthiazole synthesized in Example 1 and pyridine quaternary ammonium salt, diphenylthiourea, propynyl alcohol, OP-10, methanol and di Methylformamide is mixed uniformly according to the following mass percentages to obtain a carbon dioxide corrosion inhibitor for gas-liquid two-phase use:

[0066]

[0067] Table 4 shows the test results of different dosages of corrosion inhibitors in the medium given in Example 1, and the test period is 4 days.

[0068] Table 4 Corrosion evaluation results of corrosion inhibitors

[0069]

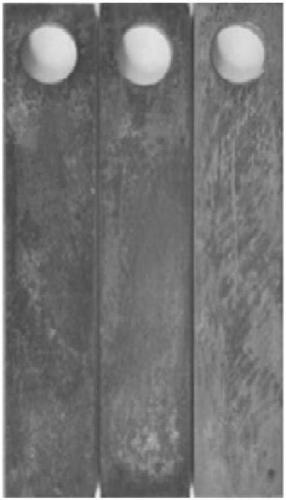

[0070] According to Table 4, when the amount of carbon dioxide corrosion inhibitor for gas-liquid two-phase is 100mg / L, the corrosion rate is: gas phase 0.0601mm / a, corrosion inhibition rate reaches 71.45%; liquid phase 0.0405mm / a, slow The corrosion rate reached 87.94%. In the gas phase medium containing carbon dioxide and the liquid phase medium with high salinity, the corrosion inhibition rate of coupon sam...

Embodiment 3

[0072] 2,5-dihydro-3,5-dimethyl-2-isopropylthiazole synthesized in Example 1 and pyridine quaternary ammonium salt, diphenylthiourea, propynyl alcohol, OP-10, methanol and di Methylformamide is mixed uniformly according to the following mass percentages to obtain a carbon dioxide corrosion inhibitor for gas-liquid two-phase use:

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com