Strawberry-like composite material and preparation method thereof

A composite material, strawberry technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, titanium compounds, etc., can solve the problems of low purity of strawberry-like composite materials, use of toxic chemical reagents, cumbersome preparation process, etc. , to achieve industrialized large-scale production, narrow particle size distribution, fast and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

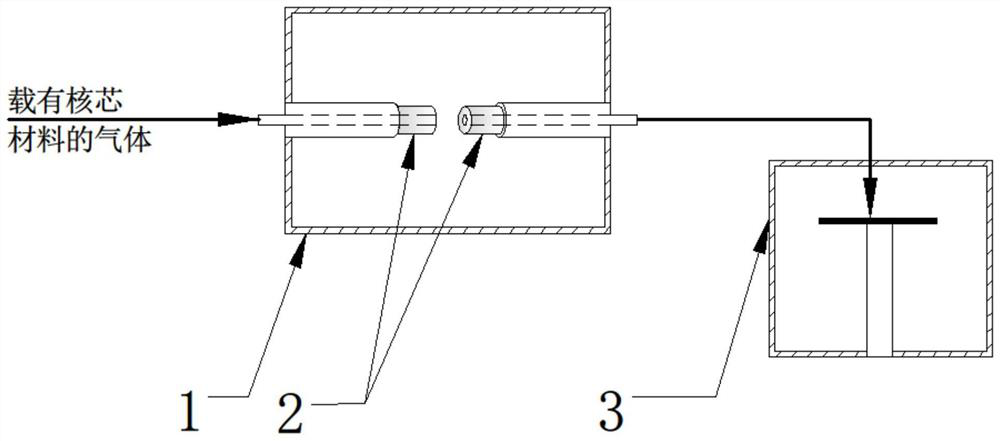

[0036] In the preparation system provided by the embodiment of the present invention, the spark ablation device is a closed container.

[0037] The carrier gas source communicates with one of the electrodes through the inlet pipeline, and the other electrode communicates with the collecting device through the gas outlet pipeline and the deposition pipeline. above the base.

[0038] The installation axes of the inlet pipeline and the outlet pipeline are on the same horizontal straight line, and are on the same horizontal straight line with the axes of the two electrodes.

[0039] The inlet pipeline is provided with a valve to control the flow rate of the carrier gas source.

[0040] In the embodiment of the present invention, the distance between the two electrodes is 0.1-3 mm.

[0041] The preparation method of strawberry shape composite material comprises the following steps:

[0042] Step 1: The carrier gas source carrying the core particles enters the spark ablation devi...

Embodiment 1

[0059] Preparation of barium titanate@silver strawberry-like composite material, the steps are as follows:

[0060] Step 1: Pass nitrogen gas carrying barium titanate particles with a particle size of 80nm into the spark ablation device at a flow rate of 2L / min;

[0061] Step 2: In the spark ablation device, a hollow cylindrical silver electrode with an inner diameter of 10 mm and a wall thickness of 2 mm is applied with a pulse voltage of 0.3 kV and 25 Hz. The spark discharge process generates high temperature to ablate and evaporate the surface materials of the two silver electrode materials ;

[0062] The silver nanoparticles produced by ablation immediately deposited on the barium titanate core particles to form barium titanate@silver strawberry-like composites.

[0063] The barium titanate@silver strawberry-shaped composite particles prepared in this example have an average core particle diameter of 80 nm, and electrode nanoparticles have an average particle diameter of ...

Embodiment 2

[0065] Preparation of silica@golden strawberry-like composite material, the steps are as follows:

[0066] Step 1: Pass helium gas carrying silicon dioxide particles with a particle size of 40nm into the spark ablation device at a flow rate of 0.5L / min;

[0067] Step 2: In the spark ablation device, a hollow cylindrical gold electrode with an inner diameter of 5mm and a wall thickness of 2mm is applied with a pulse voltage of 0.7kV and 10.7Hz. The spark discharge process generates high temperature to ablate and evaporate the surface material of the gold electrode material;

[0068] The gold nanoparticles produced by ablation were immediately deposited on the silica core particles to form the silica@gold strawberry-like composite.

[0069] The average particle diameter of the core particles of the silica@gold strawberry-shaped composite particles prepared in this example is 40nm, and the average particle diameter of the electrode nanoparticles is 10nm, which are evenly distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com