A kind of azlocillin sodium crystal and preparation method thereof

A technology of azlocillin sodium and crystal, applied to the crystal of azlocillin sodium and the field of preparation thereof, can solve the problem of improper solvent and elution agent dosage, high cost of industrialized production, easy agglomeration of azlocillin sodium, etc. problem, to achieve the effect of low production cost, short production cycle, and less toxic and side effects of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

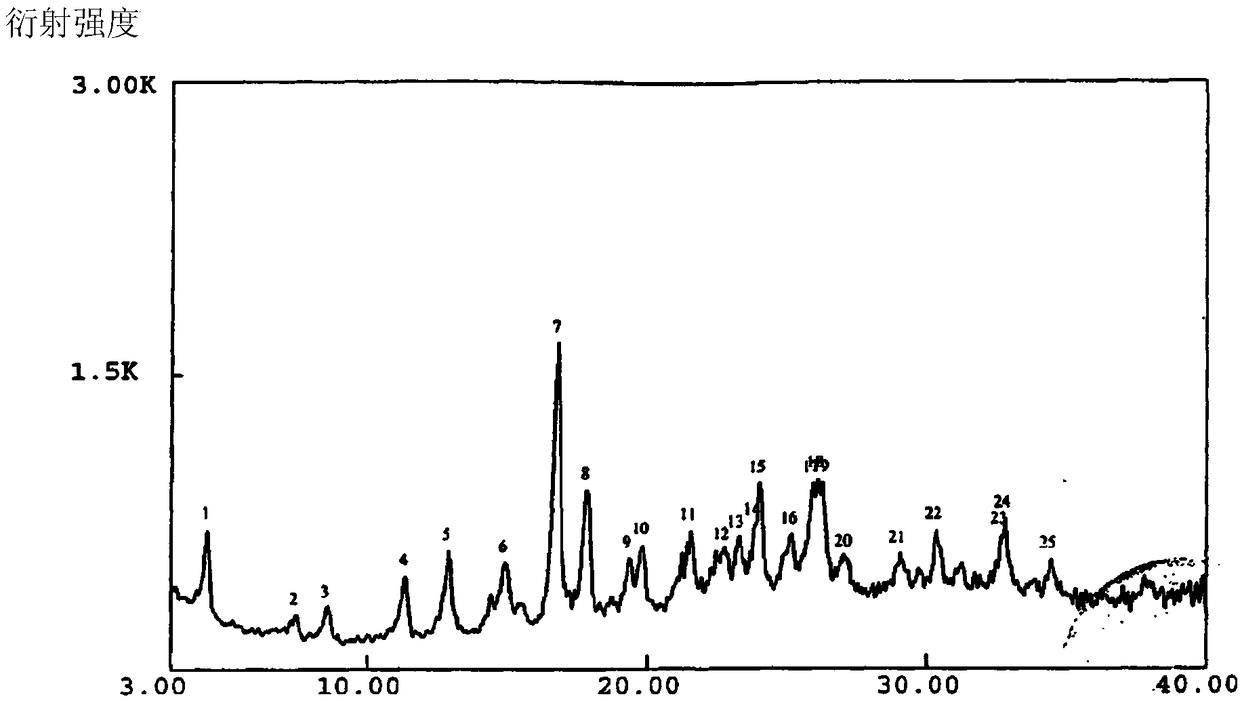

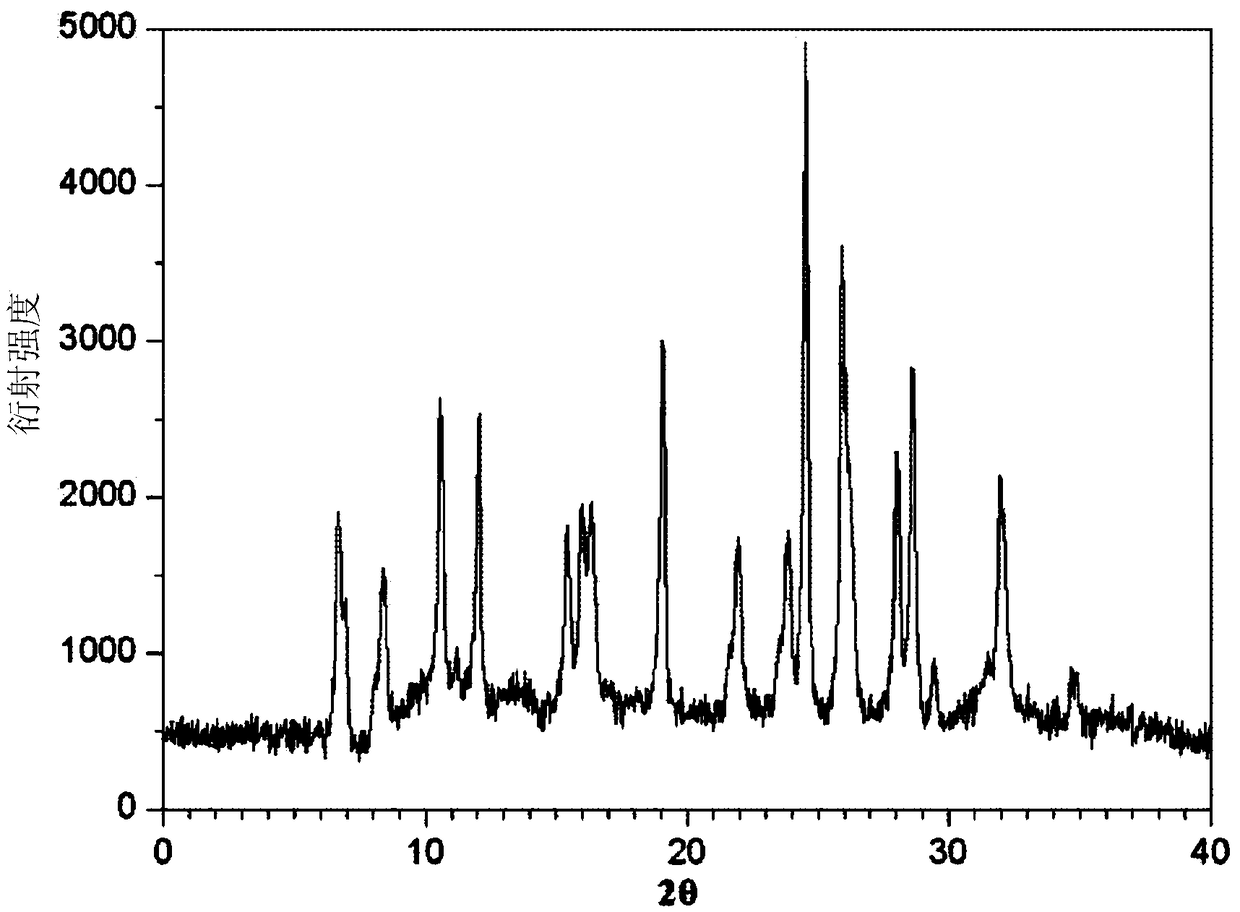

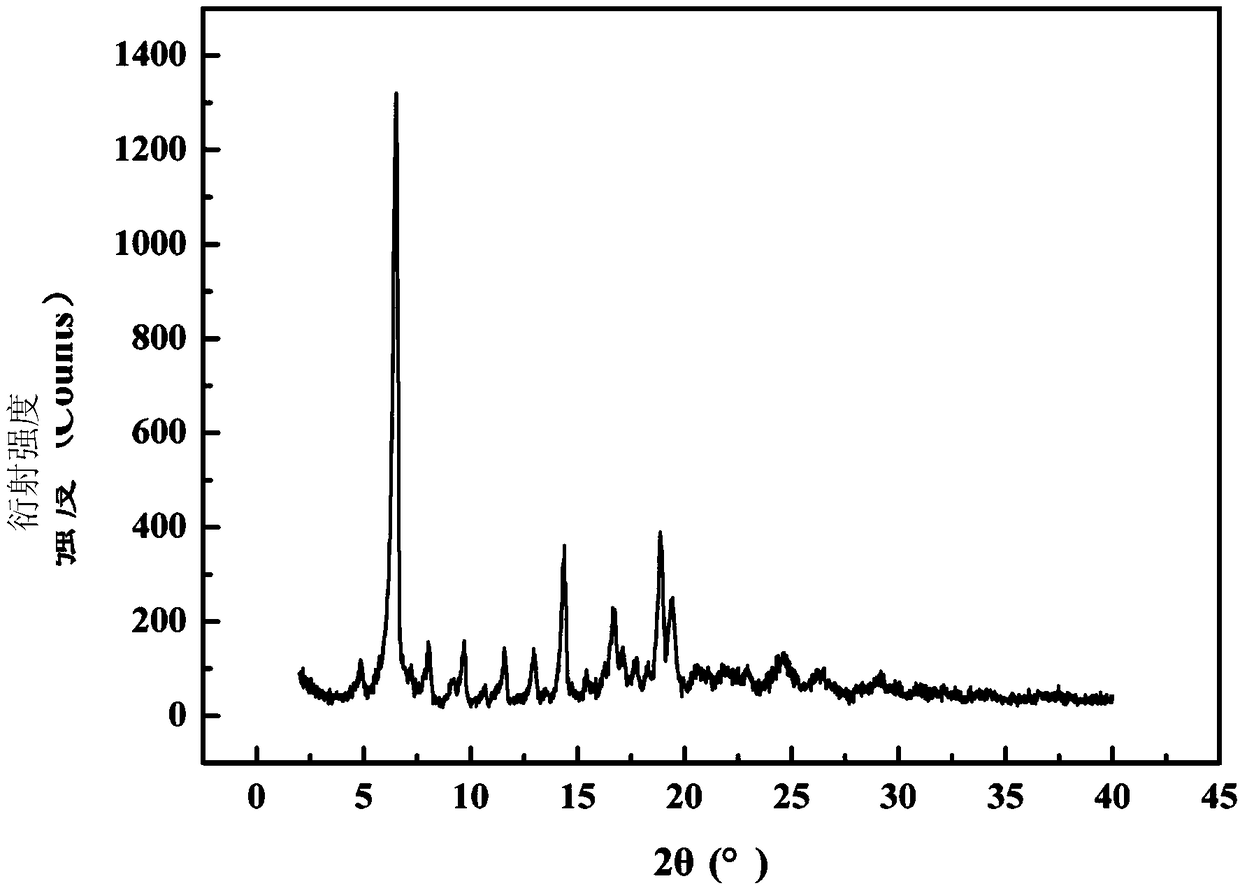

[0033] Add 3.75g of azlocillin sodium solid into 15mL of methanol, stir at 30°C until completely dissolved, then cool down to 10°C at a rate of 1.0°C / min, and add 30mL of n-propanol to the solution at a rate of 6.0ml / min , precipitated crystals, continued to stir for 6 hours, filtered with suction, and dried the obtained wet product at 25°C under normal pressure for 6 hours to obtain a new crystal form of azlocillin sodium. The X-ray powder diffraction pattern of the new crystal product is as follows: image 3 As shown, it has characteristic peaks at diffraction angles 2θ=4.92, 6.49, 7.20, 8.03, 9.18, 9.74, 10.56, 11.64, 12.91, 14.43, 15.39, 16.32, 16.57, 17.11, 17.83, 18.25, 18.90, 19.44 degrees; The TGA of the new crystalline product is as follows: Figure 4 As shown, the decomposition temperature is 217.0° C., and the solubility of the product is good; the crystal appearance is fusiform, the product purity is 99.6%, and the process yield is 95.4%.

Embodiment 2

[0035] Add 3.75g of azlocillin sodium solid into 15mL of water, stir at 30°C until completely dissolved, then cool down to 0°C at a rate of 2.0°C / min, add 90ml of ethanol to the solution at a rate of 9.0ml / min, and precipitate crystals , continue to stir for 6 hours, filter with suction, and dry the obtained wet product at 35°C under normal pressure for 3 hours to obtain a new crystal form of azlocillin sodium. , 10.49, 11.75, 12.99, 14.23, 15.28, 16.17, 16.57, 17.05, 17.86, 18.39, 19.08, and 19.51 degrees have characteristic peaks; the decomposition temperature of this new crystal form is 216.0°C, and the solubility of the product is good; the crystal appearance is Shuttle shape, product purity 99.3%, process yield 96.3%.

Embodiment 3

[0037]Add 3.00 g of azlocillin sodium solid into 15 mL of N.N-dimethylformamide, stir at 25 °C until completely dissolved, then cool down to 15 °C at a rate of 0.1 °C / min, and add to the Add 60mL of isobutanol to the solution to precipitate crystals, continue to stir for 2h, filter with suction, and dry the obtained wet product at 35°C and normal pressure for 3h to obtain a new crystal form of azlocillin sodium, which has a diffraction angle of 2θ= There are characteristic peaks at 5.08, 6.63, 7.21, 8.14, 9.38, 9.89, 10.76, 11.65, 12.97, 14.29, 15.26, 16.18, 16.62, 17.05, 17.79, 18.22, 18.95, and 19.47 degrees; the decomposition temperature of the new crystal is 218.0 °C, the solubility of the product is good; the crystal appearance is fusiform, the product purity is 99.4%, and the process yield is 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com