Cefazolin sodium compound prepared according to novel intelligent crystallization technology and preparation of cefazolin sodium compound

A technology of cefazolin sodium and its compounds, which is applied in the field of cefazolin sodium compounds and its preparations, can solve the problems of dark color and cefazolin sodium with many impurities, and achieve high separation efficiency, short crystallization time and high crystallization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 cefazolin sodium compound

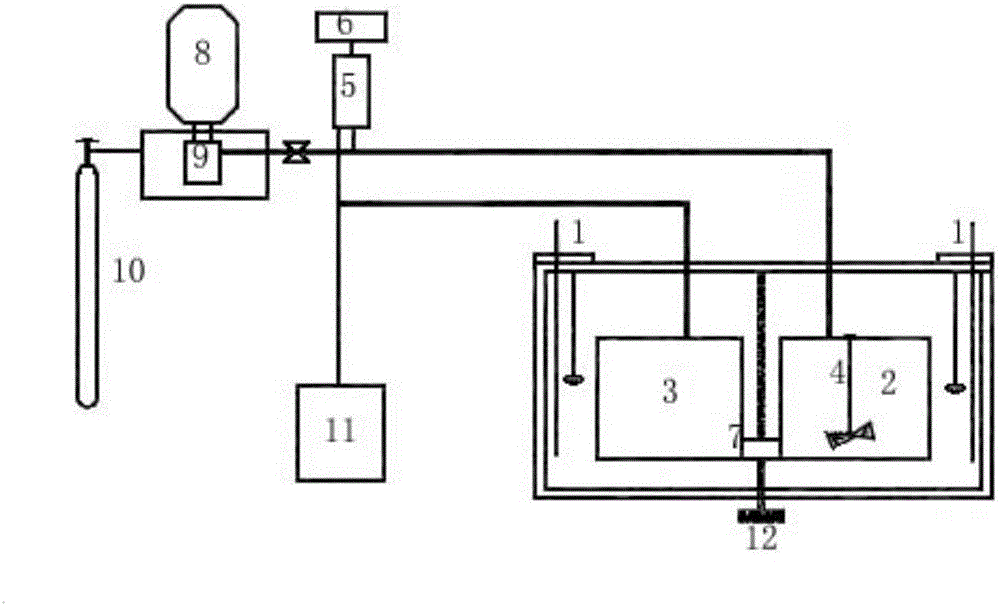

[0048] use attached figure 1 The equipment prepares cefazolin sodium compound.

[0049] (1) Take by weighing 5.06 kg of cefazolin sodium crude product with a purity of 87.6% and place it in the extraction tank, add 50 kg of mixed solvent of 40% ethanol water, control the temperature at 45° C., and stir to dissolve it;

[0050] (2) Pump in CO with a high-pressure liquid pump 2 Fluid to 10Mpa, stir, and maintain the pressure and temperature for 10 minutes, turn off the high pressure pump;

[0051] (3) Place crystal seeds in the crystallization pool, raise the height of the extraction pool to 30cm, open the quick interface of the two pools, let the liquid in the extraction pool enter the crystallization pool, and close the quick interface;

[0052] (4) Adjust the pressure in the crystallization tank to 0.5Mpa, the temperature is 10°C, and keep the temperature and pressure for 30 minutes;

[0053] (5) After the...

Embodiment 2

[0055] The preparation of embodiment 2 cefazolin sodium compound

[0056] use attached figure 1 The equipment prepares cefazolin sodium compound.

[0057] (1) Take by weighing 6.22 kg of cefazolin sodium crude product with a purity of 87.6% and place it in the extraction tank, add 60 kg of mixed solvent of 70% ethanol water, control the temperature at 55° C., and stir to dissolve it;

[0058] (2) Pump in CO with a high-pressure liquid pump 2 Fluid to 30Mpa, stir, and maintain the pressure and temperature for 20 minutes, turn off the high pressure pump;

[0059] (3) Place crystal seeds in the crystallization pool, raise the height of the extraction pool to 30cm, open the quick interface of the two pools, let the liquid in the extraction pool enter the crystallization pool, and close the quick interface;

[0060] (4) Regulate the pressure in the crystallization tank to be 0.5Mpa, the temperature is 20°C, and keep the temperature and pressure for 60 minutes;

[0061] (5) Afte...

Embodiment 3

[0063] The preparation of embodiment 3 cefazolin sodium compounds

[0064] use attached figure 1 The equipment prepares cefazolin sodium compound.

[0065] (1) Take by weighing 6.09 kg of cefazolin sodium crude product with a purity of 87.6% and place it in the extraction tank, add 70 kg of mixed solvent of 60% ethanol water, control the temperature at 50° C., and stir to dissolve it;

[0066] (2) Pump in CO with a high-pressure liquid pump 2 Fluid to 20Mpa, stir, and maintain the pressure and temperature for 15 minutes, turn off the high pressure pump;

[0067] (3) Place crystal seeds in the crystallization pool, raise the height of the extraction pool to 30cm, open the quick interface of the two pools, let the liquid in the extraction pool enter the crystallization pool, and close the quick interface;

[0068] (4) Adjust the pressure in the crystallization tank to be 6Mpa, the temperature is 15°C, and keep this temperature and pressure for 40 minutes;

[0069] (5) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com