Optimization of Microwave Radiation Preparation of Polycarboxylate Superplasticizer by Response Surface Methodology

A technology of microwave radiation and response surface method, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of low precision, inability to find the best combination and response value, deviation, etc., and achieve the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

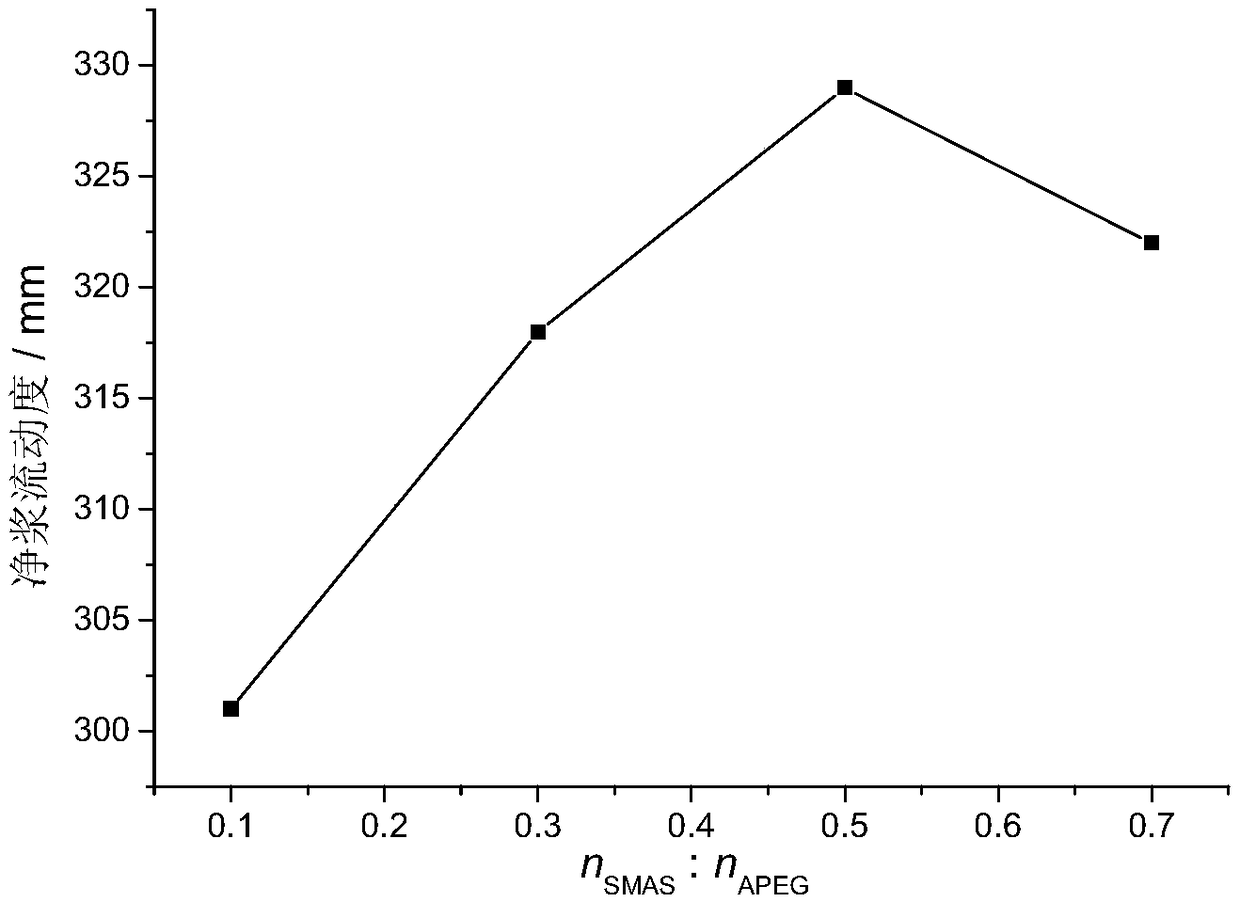

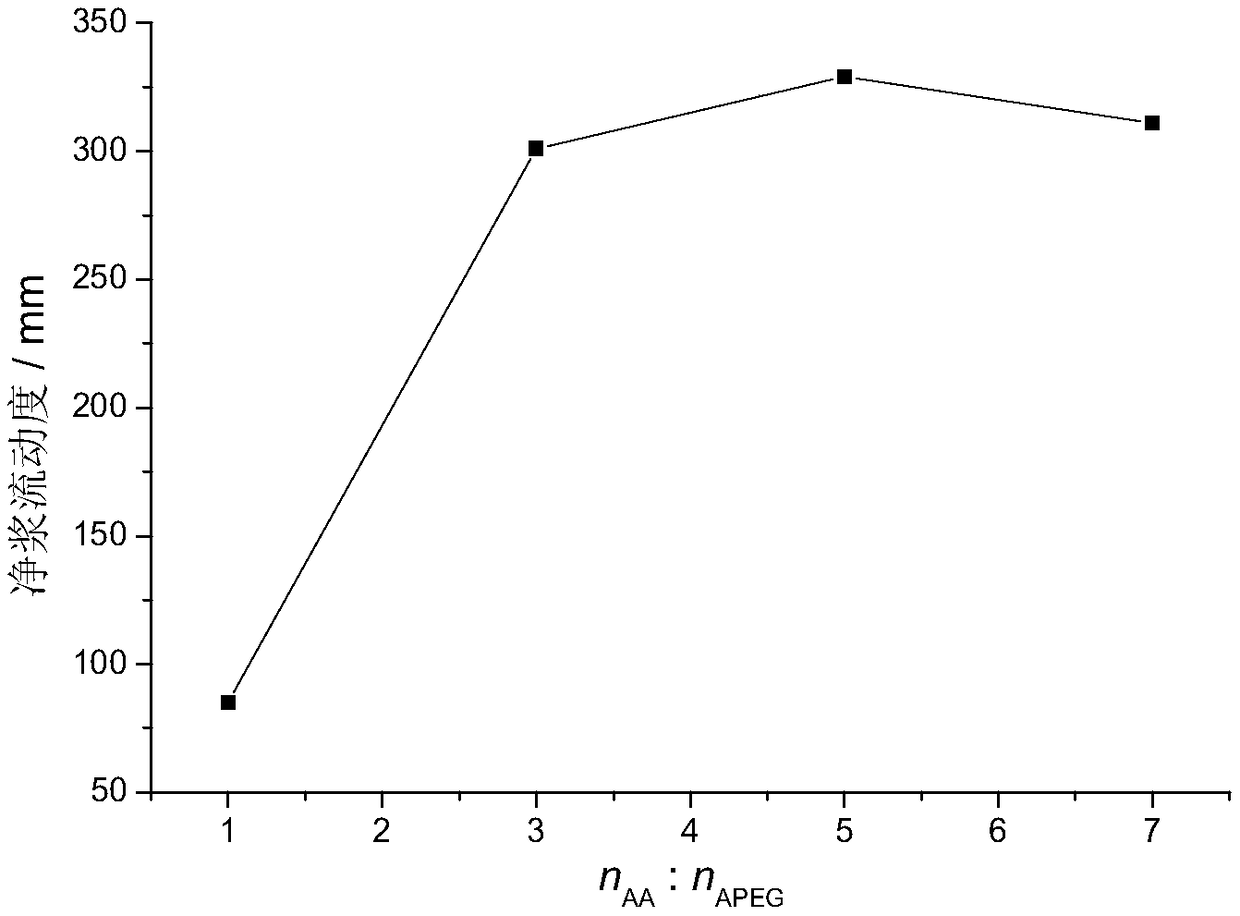

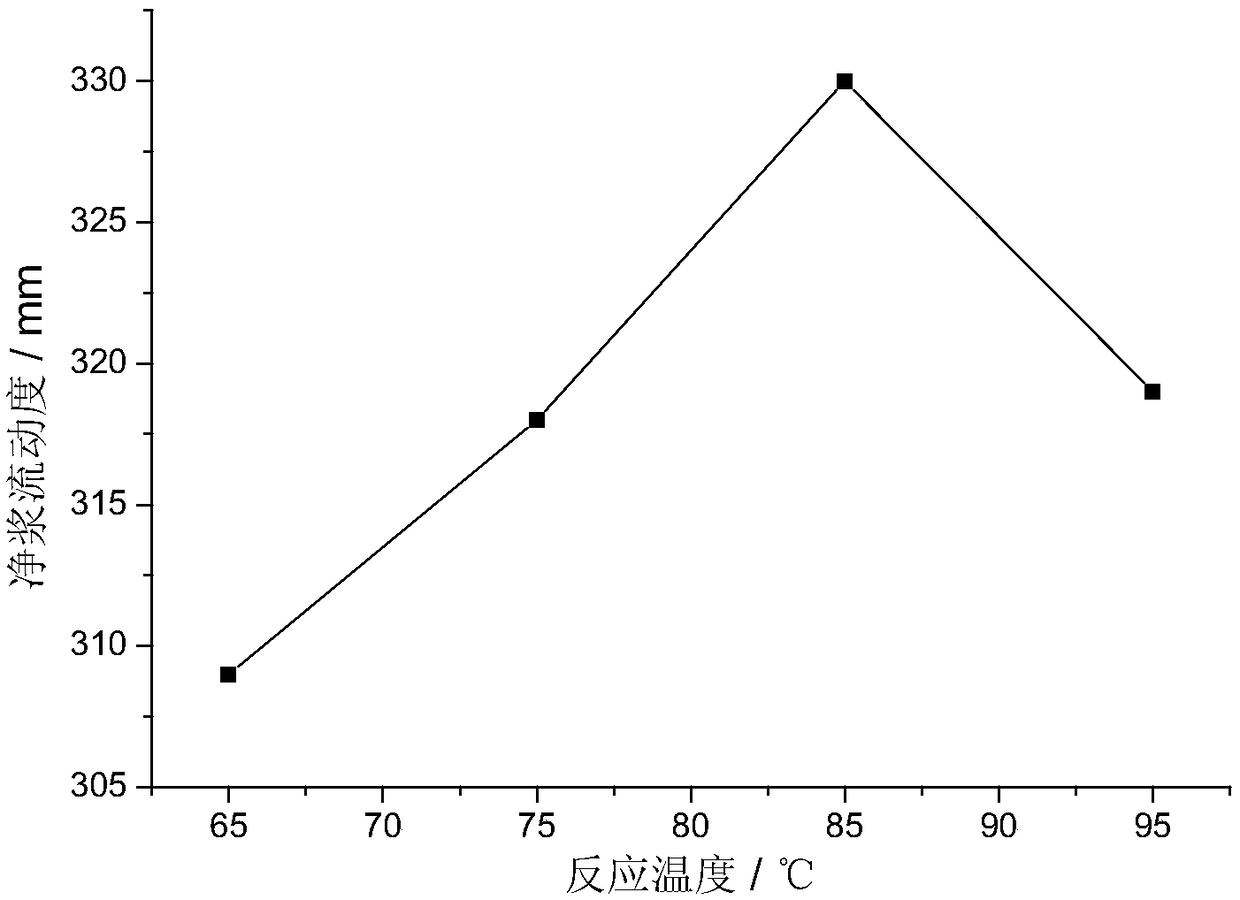

[0047] Allyl alcohol polyoxyethylene ether (APEG, M n =2400) and sodium methacryl sulfonate (SMAS) as raw materials, add water and stir to mix evenly, heat to the reaction temperature under microwave radiation conditions, then add acrylic acid (AA) and ammonium persulfate (APS) at constant temperature to react for a period of time, utilize the response The surface method is used to set the variable parameters of the reaction. After the reaction is completed, cool down and adjust the pH to obtain the polycarboxylate superplasticizer. Specifically include the following steps:

[0048] 1. Sample preparation

[0049] Add a certain proportion of the mixed solution of allyl alcohol polyoxyethylene ether and sodium methpropylene sulfonate into a dry four-necked flask equipped with a reflux condenser, stirrer, and thermometer, turn on the microwave reactor, and adjust the microwave power to 300W , after the temperature of the mixed solution is raised to the temperature required by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com