Self-catalytic anacardol/lignin-based polyurethane foam and preparation method thereof

A polyurethane foam and lignin-based technology, which is applied in the field of self-catalyzed polyurethane foam and its preparation, can solve environmental and human health hazards and other problems, and achieve the effect of high activity, rich and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

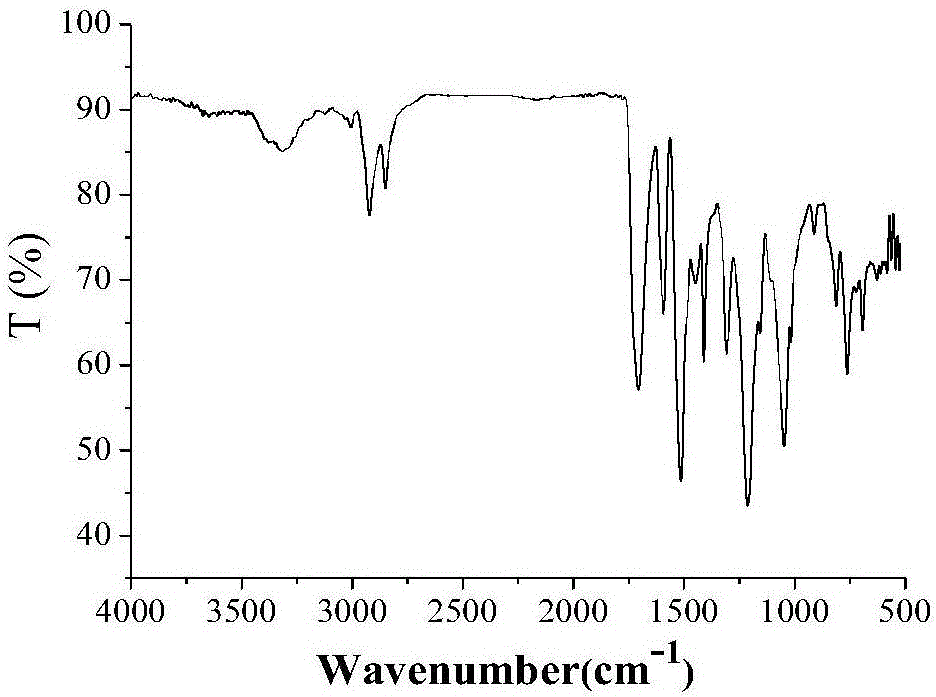

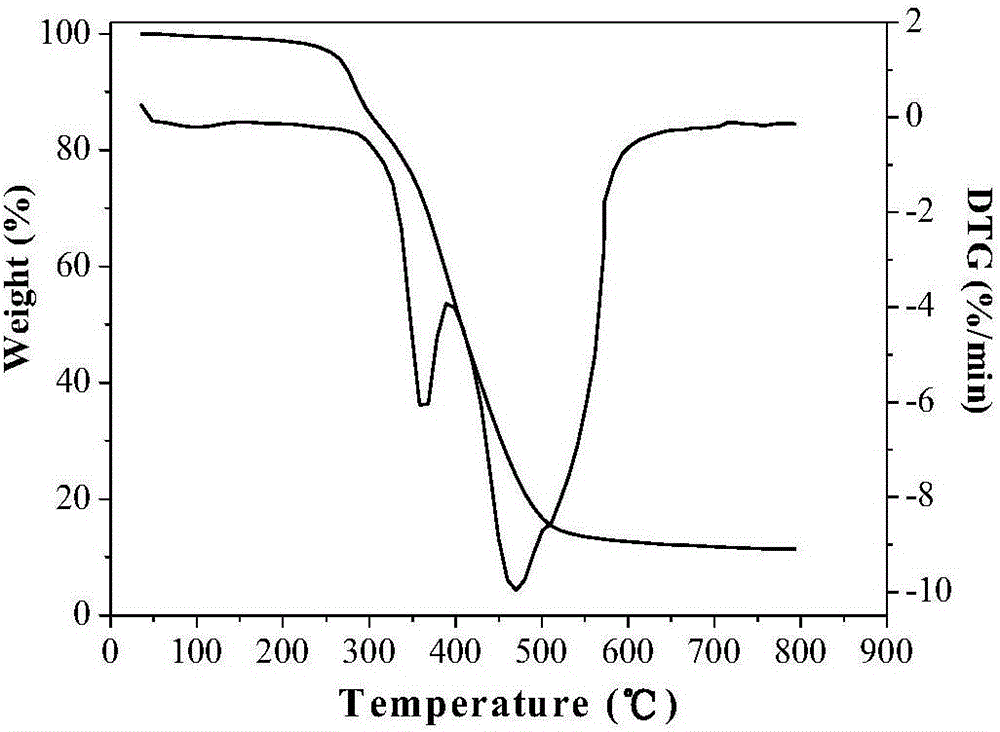

[0034] The self-catalyzed cardanol-based polyol (Ⅰ) was prepared by ring-opening cardanol after epoxidation and diethanolamine, with a hydroxyl value of 365 mg / g and a viscosity of 3060 mPa·s; 10%.

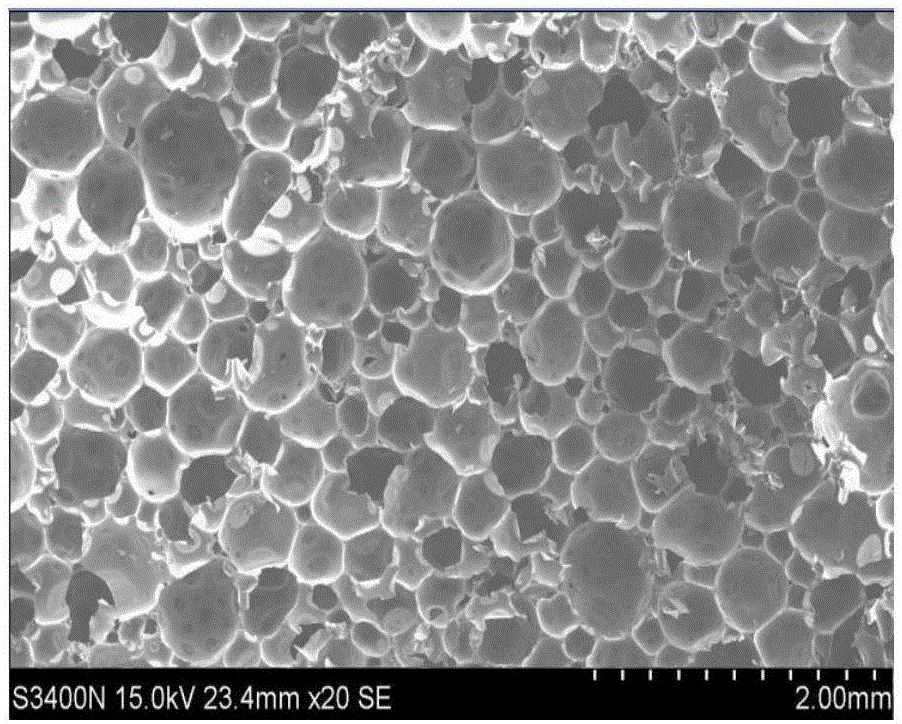

[0035] Mix 100.0g of cardanol-based polyol (I), 10.0g of lignin, 1.0g of deionized water and 2.5g of silicone oil evenly, then quickly add 135.4g of PAPI, stir quickly and mix well, then pour into the mold to foam freely. After the foam is cured at room temperature for 7 days, the compressive strength is 0.40MPa and the apparent density is 79.74kg / m 3 .

Embodiment 2

[0037] The self-catalyzed cardanol-based polyol (Ⅰ) was prepared by ring-opening cardanol after epoxidation and diethanolamine, with a hydroxyl value of 365 mg / g and a viscosity of 3060 mPa·s; 20%.

[0038] Mix 100.0g of cardanol-based polyol (I), 20.0g of lignin, 1.0g of deionized water and 2.5g of silicone oil evenly, then quickly add 151.6g of PAPI, stir quickly and mix well, pour into the mold to foam freely. After the foam is cured at room temperature for 7 days, the compressive strength is 0.44MPa and the apparent density is 81.84kg / m 3 .

Embodiment 3

[0040] The self-catalyzed cardanol-based polyol (Ⅰ) was prepared by ring-opening cardanol after epoxidation and diethanolamine, with a hydroxyl value of 365 mg / g and a viscosity of 3060 mPa·s; 5%.

[0041] Mix 100.0g of cardanol-based polyol (I), 5.0g of lignin, 1.0g of deionized water and 2.5g of silicone oil evenly, then quickly add 127.3g of PAPI, stir quickly and mix well, then pour into the mold to foam freely. After the foam is cured at room temperature for 7 days, the compressive strength is 0.36MPa and the apparent density is 77.39kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com