Preparation method of polyetherketone powder consumables for laser sintering forming 3D printing

A 3D printing and laser sintering technology, applied in the direction of additive processing, etc., can solve the problems of increasing costs and achieve the effects of saving production costs, good compatibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

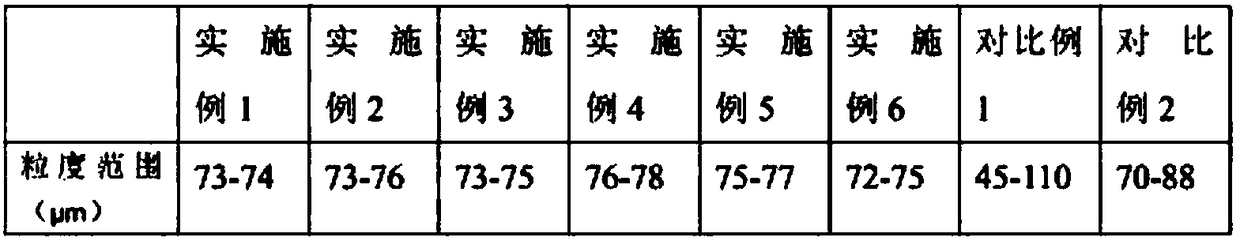

Examples

preparation example Construction

[0025] The invention provides a preparation method of laser sintering forming 3D printing polyether ketone powder consumables, comprising the following steps:

[0026] (1) Put the polyether ketone into the silo of the low-temperature pulverizer, and use the liquid nitrogen built in the silo to cool the polyether ketone to -150°C ~ -196°C";

[0027] (2) Pulverizing the cooled polyetherketone in step (1), the pulverization temperature is -140°C to -196°C to obtain primary polyetherketone powder;

[0028] (3) After sieving the primary polyether ketone powder in step (2), place it in an adjustable heating device, and dry it with a gradient temperature rise at 90°C. After ℃, dry at constant temperature for 0.5h~2h;

[0029] (4) adding the pulverized powder in step (3) into a grinder, and fully grinding to obtain a crude polyetherketone product;

[0030] (5) Dry the crude polyether ketone product in step (4) at 90°C with a gradient temperature rise rate of 2°C / min to 8°C / min, then...

Embodiment 1

[0045] A method for preparing polyetherketone powder consumables for laser sintering forming 3D printing, comprising the following steps:

[0046] (1) Add 10g of polyether ketone into the cooling chamber from the upper part and move it downward; add liquid nitrogen from the bottom and move it upwards, and reverse the movement for immersion cooling, and cool the material to -196°C for 3 hours;

[0047] (2) The polyether ketone cooled in step (1) is pulverized by a vibrating ball mill at a pulverization temperature of -196°C for 2 hours to obtain primary polyether ketone powder;

[0048] (3) After sieving the primary polyetherketone powder in step (2), place it in an adjustable heating device, and dry it with a gradient temperature rise at 90°C, with a heating frequency of 5°C / min, and then heat it up to 120°C and then dry it at a constant temperature for 2 hours ;

[0049] (4) Add the pulverized powder in step (3) into a grinder, and grind for 2 hours under the condition of su...

Embodiment 2

[0052] A method for preparing polyetherketone powder consumables for laser sintering forming 3D printing, comprising the following steps:

[0053] (1) Add 10g of polyether ketone into the cooling chamber from the upper part and move it downward; add liquid nitrogen from the bottom and move it upwards, reverse the immersion cooling, and cool the material to -180°C for 4 hours;

[0054] (2) The polyether ketone cooled in step (1) is pulverized by a vibrating ball mill at a pulverization temperature of -180°C for 2 hours to obtain primary polyether ketone powder;

[0055] (3) After sieving the primary polyetherketone powder in step (2), place it in an adjustable heating device, and dry it with a gradient temperature rise at 90°C, with a heating frequency of 5°C / min, and then heat it up to 120°C and then dry it at a constant temperature for 2 hours ;

[0056] (4) Add the pulverized powder in step (3) into a grinder, and grind for 1.8 hours under the condition of sufficient grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com