Quantum dot material as well as preparation method, quantum dot film, backlight module and display equipment

A technology of quantum dot material and quantum dot film, which is applied in the field of liquid crystal display, can solve the problems of affecting the display effect of liquid crystal display equipment, low luminous efficiency of quantum dot film, and affecting the brightness of backlight module, etc., so as to improve the display effect and reduce the overlap rate , Improve the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

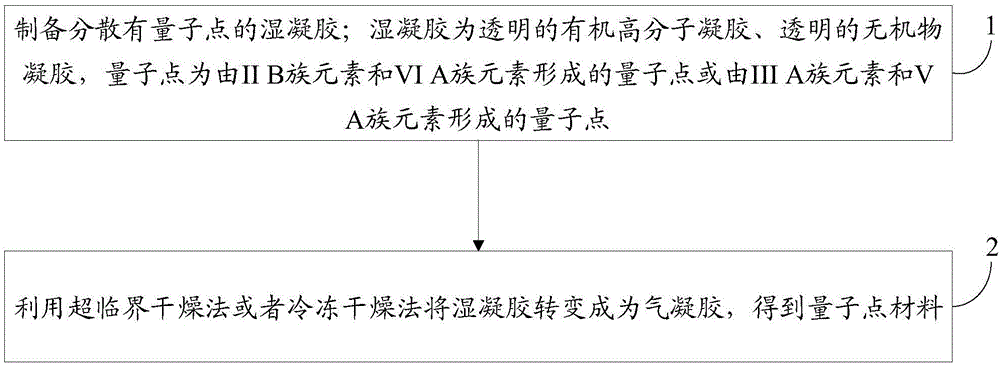

[0047] In the first aspect, the embodiment of the present invention provides a method for preparing a quantum dot material, see figure 2 , the preparation method comprises the following steps:

[0048] Step 1, preparing a wet gel dispersed with quantum dots; the wet gel is a transparent organic polymer gel or a transparent inorganic gel, and the quantum dots are quantum dots formed by II B group elements and VI A group elements Or quantum dots formed of Group III A elements and Group V A elements.

[0049] Step 2, using a supercritical drying method or a freeze drying method to convert the wet gel into an aerogel to obtain a quantum dot material.

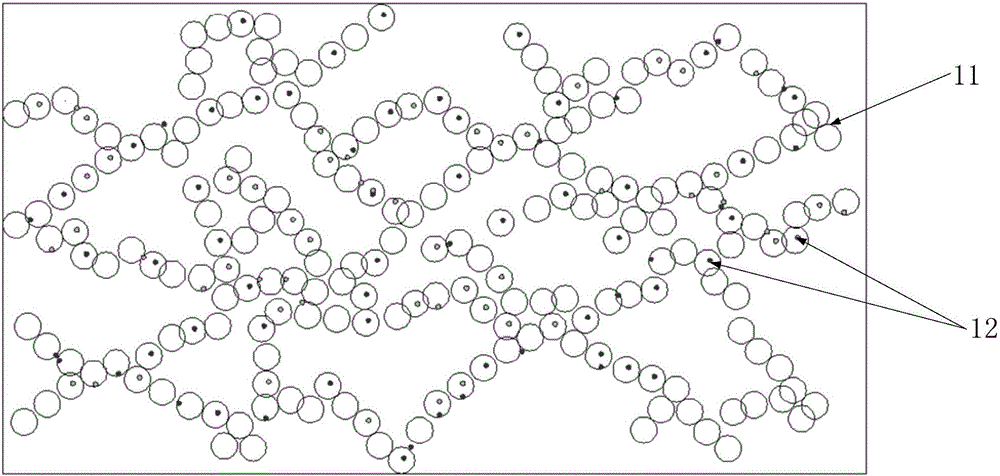

[0050] In the existing quantum dot film, the quantum dots are directly mixed with the matrix, but the particle size of the quantum dots is usually nanoscale, which makes the quantum dots easy to agglomerate in the matrix, making the quantum dots overlap. In the process of photoluminescence, the overlapping of quantum dots will ca...

Embodiment 1

[0082] An embodiment of the present invention provides a quantum dot material and a preparation method thereof. The quantum dot material uses resorcinol-formaldehyde airgel as a matrix to load quantum dots, and utilizes the three-dimensional network structure of resorcinol-formaldehyde airgel to make Quantum dots are evenly dispersed to prevent quantum dots from agglomerating. In the quantum dot material provided in this embodiment, the quantum dots used are CdSe quantum dots, and the particle size of the quantum dots is 2-10 nm.

[0083] The preparation method of the quantum dot material provided in this embodiment is as follows:

[0084] Step 101, preparation of resorcinol-formaldehyde wet gel;

[0085] Step 1011, stirring and mixing resorcinol and formaldehyde at normal temperature, the molar ratio of resorcinol and formaldehyde is 1:2;

[0086] Step 1012, mixing the above-mentioned CdSe quantum dots with methanol, emulsifying and mixing uniformly;

[0087]Step 1013, qui...

Embodiment 2

[0095] An embodiment of the present invention provides a quantum dot material and a preparation method thereof. The quantum dot material uses resorcinol-formaldehyde airgel as a matrix to load quantum dots, and utilizes the three-dimensional network structure of resorcinol-formaldehyde airgel to make Quantum dots are evenly dispersed to prevent quantum dots from agglomerating. In the quantum dot material provided in this embodiment, the quantum dots used are CdTe quantum dots, and the particle size of the quantum dots is 2-10 nm.

[0096] The preparation method of the quantum dot material provided in this embodiment is as follows:

[0097] Step 201, preparation of resorcinol-formaldehyde wet gel;

[0098] Step 2011, stirring and mixing resorcinol and formaldehyde at normal temperature, the molar ratio of resorcinol and formaldehyde is 1:2;

[0099] Step 2012, mixing the above-mentioned CdTe quantum dots with methanol, emulsifying and mixing uniformly;

[0100] In step 2013,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com