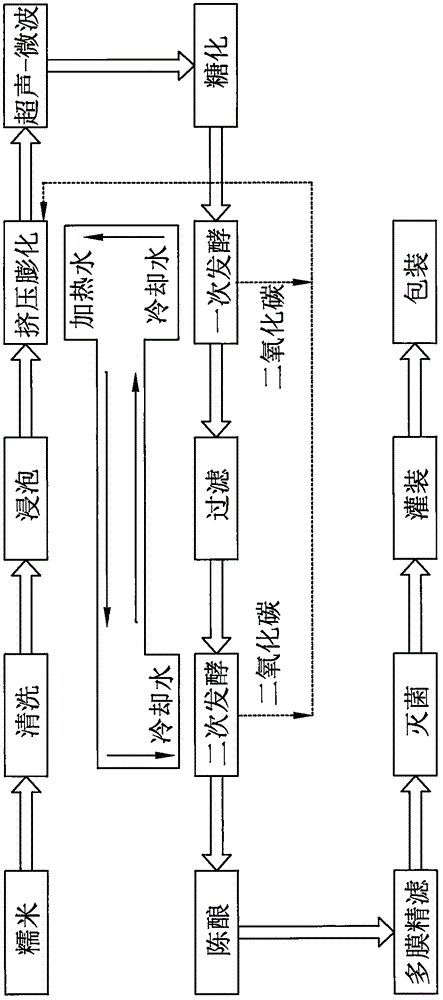

Brewing process of low-sugar rice wine

A rice wine and process technology, applied in the field of low-sugar rice wine brewing technology, can solve the problems of high energy consumption, low utilization rate, and high cost, and achieve the effects of reducing production energy consumption, extending shelf life, and reducing sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

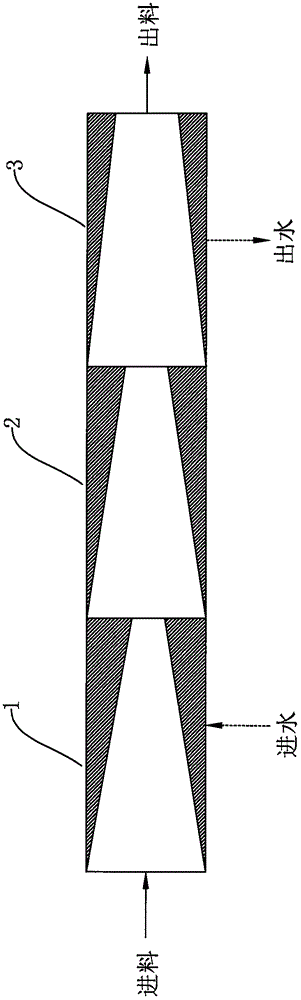

[0030] Wash 100 kg of fresh glutinous rice with water, then soak it in 150 kg of clear mountain spring water for 1 hour, and then add citric acid buffer to adjust the pH of the slurry to 5. Feed the slurry into the extrusion expansion device at a speed of 50kg / h, set the screw speed of the first stage to 800r / min and the expansion temperature to 150℃; the screw speed of the second stage to 700r / min and the expansion temperature to 130℃; The third stage screw speed is 600r / min, and the expansion temperature is 110°C. The puffed slurry was subjected to ultrasonic-microwave treatment, the ultrasonic power was 400W, the frequency was 500kHz; the microwave power was 150W, the frequency was 50GHz; the treatment time was 10min. Inoculate the treated slurry with a saccharified koji composed of 30% yeast and 70% aspergillus; the saccharified koji inoculation amount is 5‰ of the slurry, and the saccharified koji and the slurry are mixed uniformly by mechanical stirring; the saccharificat...

Embodiment 2

[0032] Wash 100 kg of fresh glutinous rice with water, then soak it in 150 kg of clear mountain spring water for 1 hour, and then add citric acid buffer to adjust the pH of the slurry to 5. Feed the slurry into the extrusion expansion device at a speed of 50kg / h, set the screw speed of the first stage to 900r / min and the expansion temperature to 150℃; the screw speed of the second stage to 800r / min and the expansion temperature to 130℃; The third stage screw speed is 600r / min, and the expansion temperature is 110°C. The puffed slurry was subjected to ultrasonic-microwave treatment, the ultrasonic power was 400W, the frequency was 500kHz; the microwave power was 150W, the frequency was 50GHz, and the treatment time was 8min. Saccharified koji composed of 40% yeast and 60% Aspergillus are inoculated into the treated slurry; the inoculation amount of saccharified koji is 5‰ of the slurry, and the saccharified koji and the slurry are mixed uniformly by mechanical stirring; the sacc...

Embodiment 3

[0034] Wash 100 kg of fresh glutinous rice with water, then soak it in 150 kg of clear mountain spring water for 1 hour, and then add citric acid buffer to adjust the pH of the slurry to 5. Feed the slurry into the extrusion expansion device at a speed of 50kg / h, set the screw speed of the first stage to 800r / min and the expansion temperature to 150℃; the screw speed of the second stage to 700r / min and the expansion temperature to 130℃; The third stage screw speed is 600r / min, and the expansion temperature is 110°C. The puffed slurry was subjected to ultrasonic-microwave treatment, the ultrasonic power was 400W, the frequency was 500kHz; the microwave power was 150W, the frequency was 50GHz; the treatment time was 15min. Inoculate the treated slurry with a saccharified koji composed of 30% yeast and 70% aspergillus; the saccharified koji inoculation amount is 5‰ of the slurry, and the saccharified koji and the slurry are mixed uniformly by mechanical stirring; the saccharificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com