Method for improving coal seam permeability based on acidification means

A permeability and coal seam technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of changing the conductivity of coal seams, low permeability, small influence range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

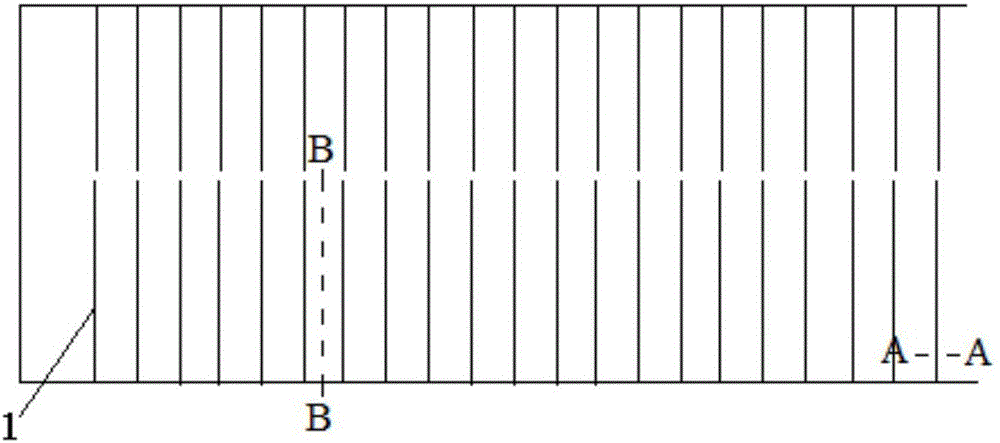

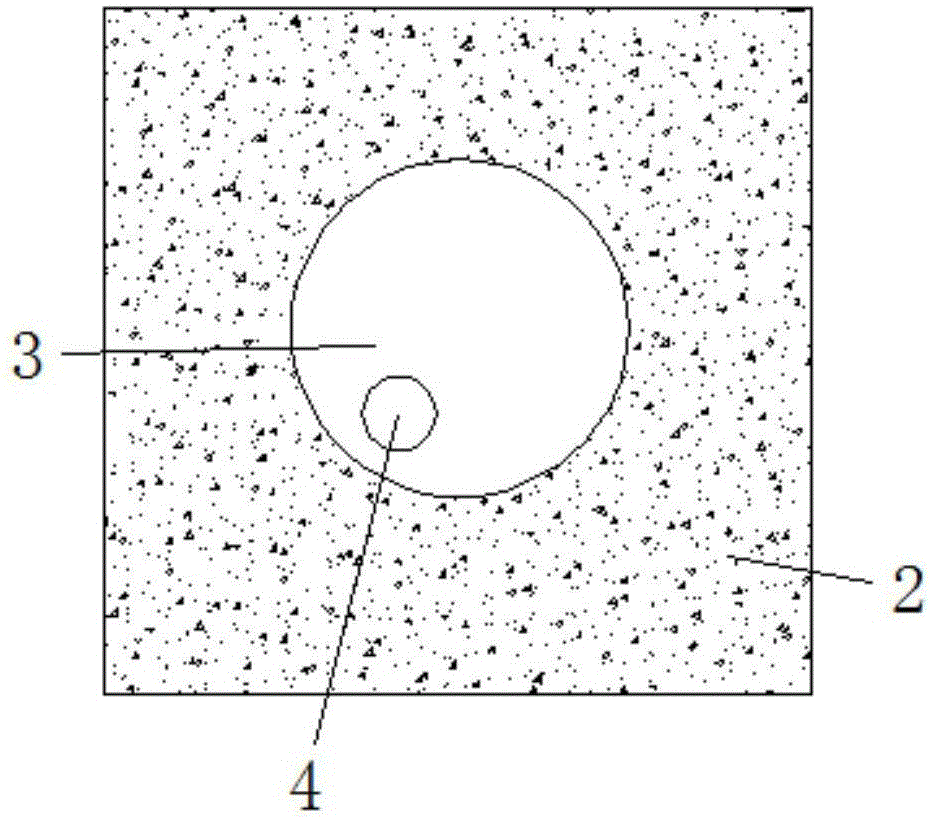

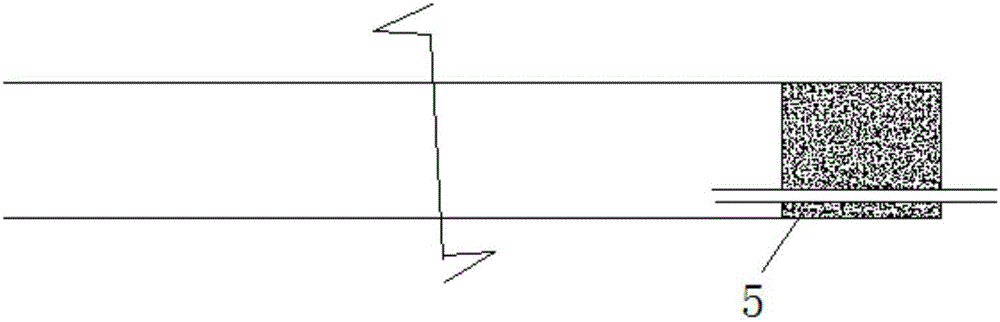

[0017] A method for increasing coal seam permeability based on acidification means, the method is carried out according to the following steps: before mining at the working face, drill holes along the coal seam in parallel construction along the direction of the coal seam in the backwind channel of the working face and work In the surface transportation trough, parallel construction along the coal seam inclination is used to drill holes in the upward direction with equal hole spacing. At the same time, conduits are used to connect the drilling holes, and polyurethane materials are used to seal the holes, such as figure 1 , 2 , shown in 3, inject a sufficient amount of acidic solution into the sealed borehole by the conduit (the aperture of the conduit is 10mm), and finally seal the conduit; the acidic solution is composed of the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com