Axial feeding integrated type SCR aftertreatment mixing cavity

An integrated, mixing chamber technology, applied in mufflers, engine components, machines/engines, etc., can solve the problems of incomplete exhaust gas treatment, insufficient mixing of exhaust gas and ammonia gas, etc., to improve gas mixing efficiency and save mixing time. , Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

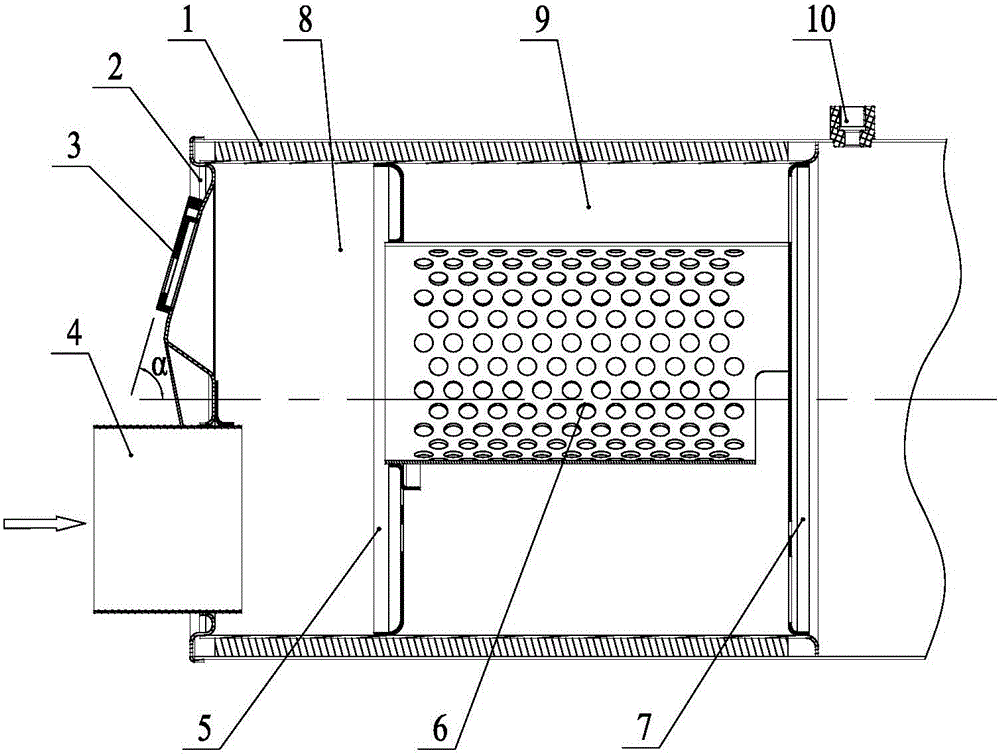

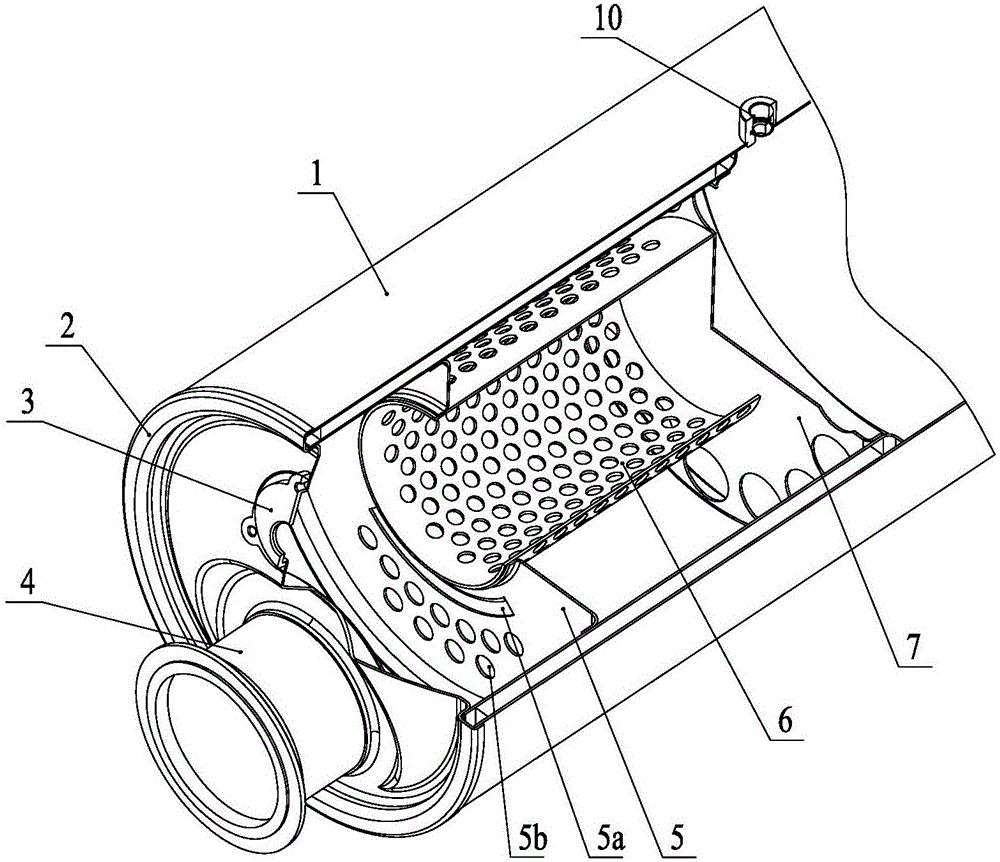

[0018] As shown in the figure: the shaft-entry integrated SCR post-treatment mixing chamber in the embodiment is mainly composed of a mixing cylinder 1, an end cover 2, an injection base 3, an air inlet 4, a front baffle 5, a mixing tube 6, and a rear baffle 7 and temperature sensor 10 and so on.

[0019] Such as figure 1 , figure 2 As shown, the inside of the mixing cylinder 1 is provided with a front partition 5 and a rear partition 7, the space before the front partition 5 forms a front cavity 8, and between the front partition 5 and the rear partition 7 The space constitutes the rear cavity 9, the front partition 5 and the rear partition 7 are provided with through holes; the front opening of the mixing cylinder 1 is provided with an end cover 2, and the end cover 2 is provided with a urea nozzle The base 3 and the air inlet 4 communicated with the fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com