Inclined throwing optical fiber refractive index sensor and its preparation method

A technology of a refractive index sensor and a manufacturing method, which is applied in the field of oblique throwing optical fiber refractive index sensor and its preparation, can solve problems such as difficulty in finding connection methods and sensing circuits, and achieve low cost, large linear measurement range, and reliability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

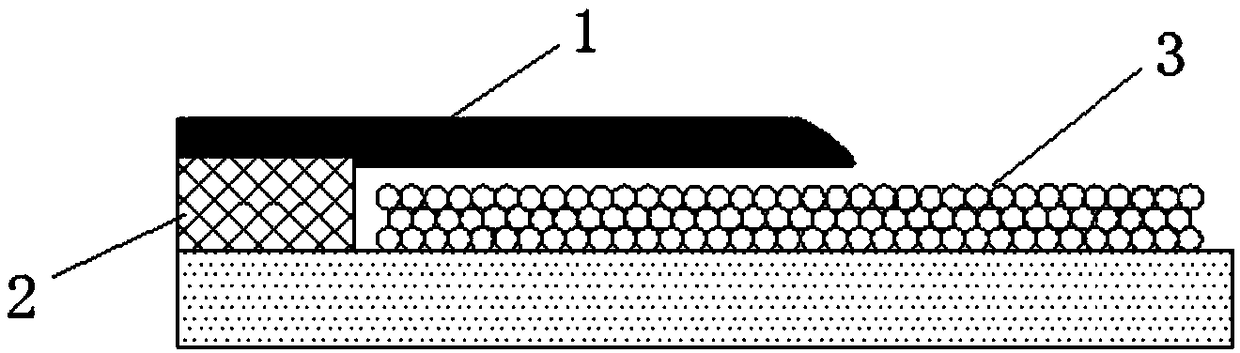

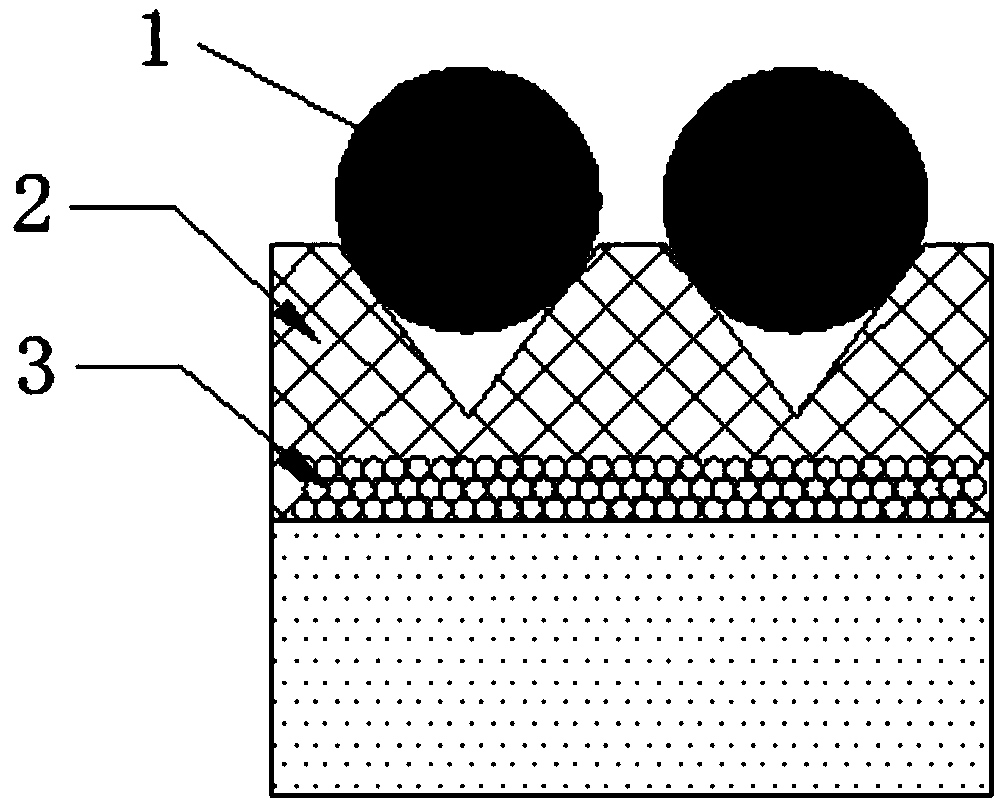

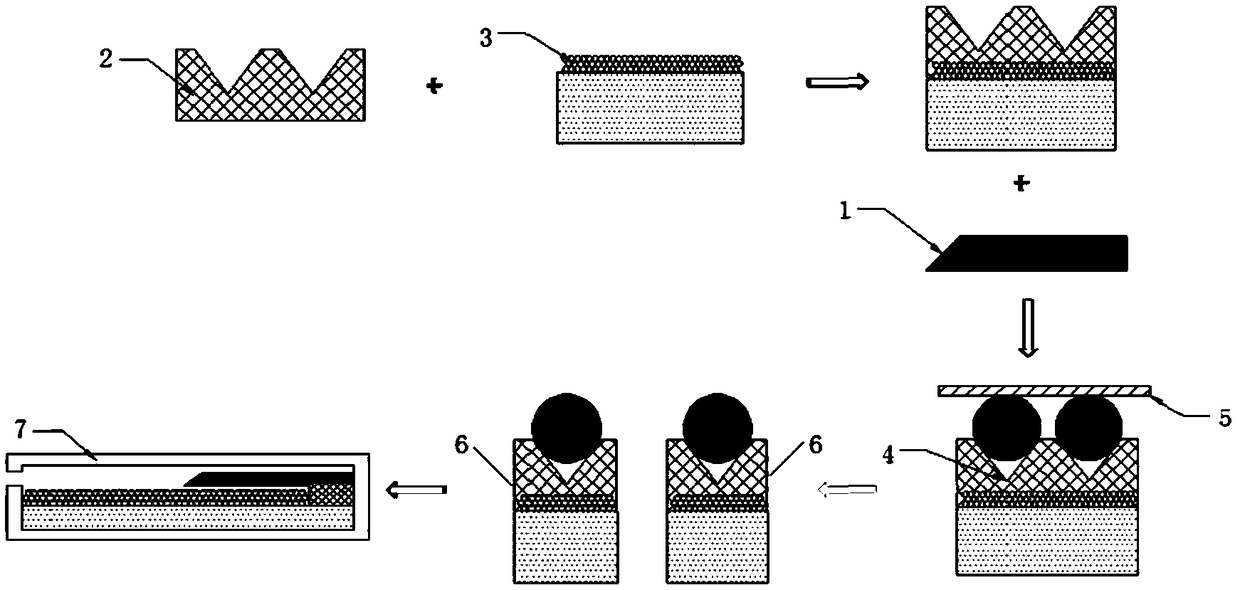

[0021] Further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

[0022] The steps of preparing oblique throwing optical fiber refractive index sensor in this embodiment are as follows:

[0023] a) RCA standard cleaning of two identical silicon wafers by wet chemical cleaning method, followed by ultrasonic cleaning with acetone, alcohol, and deionized water for 5 minutes, and then drying with nitrogen.

[0024] b) Fabrication of V-shaped fiber groove array. Firstly, single-crystal silicon is oxidized on both sides, and silicon nitride is deposited on one side to form a protective layer. Then make a mask plate, open a window by photolithography, and selectively remove the protective layer to form a V-shaped optical fiber groove 2 array pattern. Then use KOH solution to carry out wet etching of the silicon wafer, and control the reaction time to obtain the required depth of the optical fiber groove. Finally, silicon oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com