Preparation method of RGO (reduced graphene oxide) thin film moisture-sensitive sensor

A technology of humidity sensitive sensor and graphene film, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of peeling off, easy expansion or contraction of the humidity sensing layer, etc., to improve adhesion, enhance interaction force, The effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

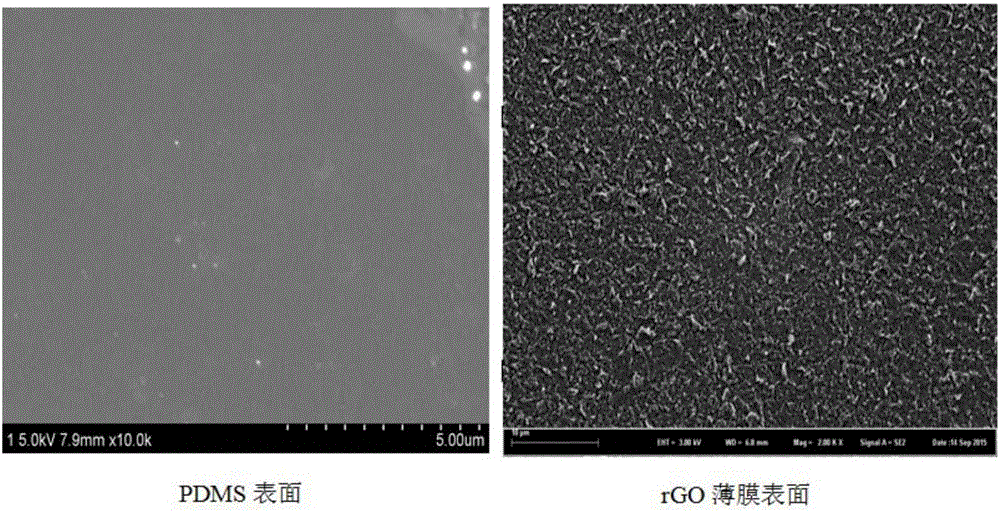

[0016] Embodiment 1: a kind of preparation method of reduced graphene oxide film humidity sensor, comprises the following contents:

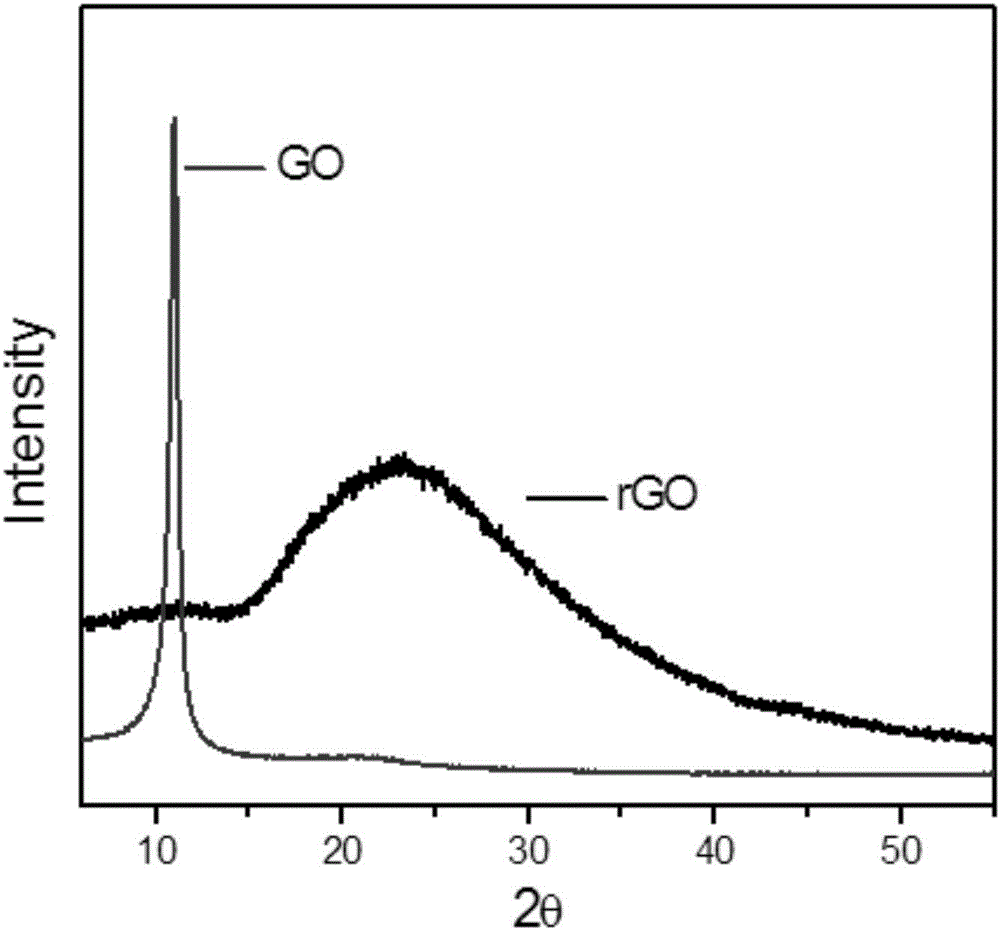

[0017] (1) The preparation method of graphene oxide is: slowly mix 270mL concentrated sulfuric acid / phosphoric acid mixed acid (H 2 SO 4 :H 3 PO 3 =9:1, V / V) was added dropwise to a beaker with 2g of natural graphite powder and kept stirring, then slowly added 12g of potassium permanganate, after mixing evenly, the beaker was transferred to a 50°C water bath for 12h. After the reaction was completed, 300 mL of ice water was added into the beaker, and after cooling to room temperature, 5 mL of 30% hydrogen peroxide was added dropwise to obtain a bright yellow product. Finally, the product was centrifuged and washed with hydrochloric acid and deionized water until pH = 6 at a rotation speed of 8000 rpm / min, and finally freeze-dried to obtain graphene oxide.

[0018] (2) The preparation method of reduced graphene oxide is as follows: measure 1....

Embodiment 2

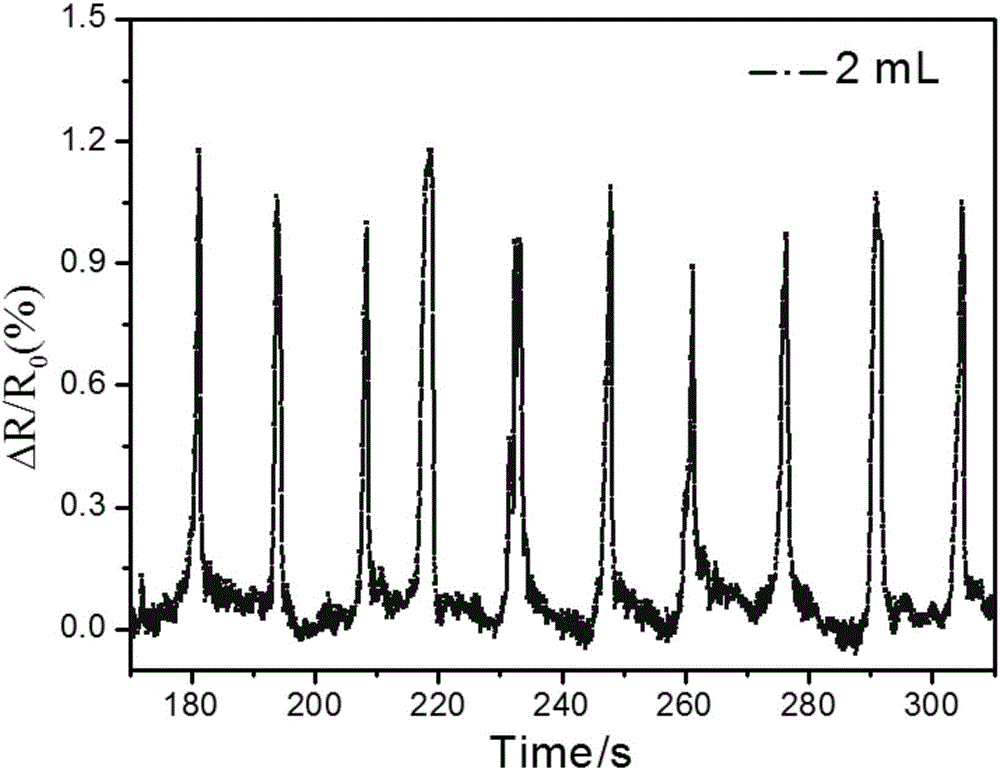

[0026] Embodiment 2: In this embodiment, by changing the magnetron sputtering parameters, the effect of the gold electrode deposition on the sensor characteristics is studied.

[0027] Steps 1-5, 7 are the same as in Embodiment 1, and the magnetron sputtering parameters in step 6 are shown in Table 1-Table 6.

[0028] Table 1: Vacuum degrees of different backgrounds

[0029]

[0030] Note: The sputtering pressure is 1.0Pa, the sputtering power is 60W, the sputtering time is 7.5min, the target base distance is 50mm, and the gas flow rate is 23sccm.

[0031] Table 2: Different sputtering pressures

[0032]

[0033] Note: back vacuum 6.0-4.0×10 -4 Pa, the sputtering power is 60W, the sputtering time is 7.5min, the target base distance is 50mm, and the gas flow rate is 23sccm.

[0034] Table 3: Different sputtering power

[0035] Sputtering power 10W 30W 50W 60W 70W 90W 130W film integrity 5% 60% 85% 100% 95% 80% 50%

[0036] Note: back va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com