Visible broad-spectrum depolarizing beam splitter

A depolarized spectroscopic and wide-spectrum technology, which is applied in the field of spectroscopic sheets, can solve the problems of complex processing technology, low final yield, and high processing cost, and achieve the effects of simple physical structure and optical structure, reduced processing cost, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

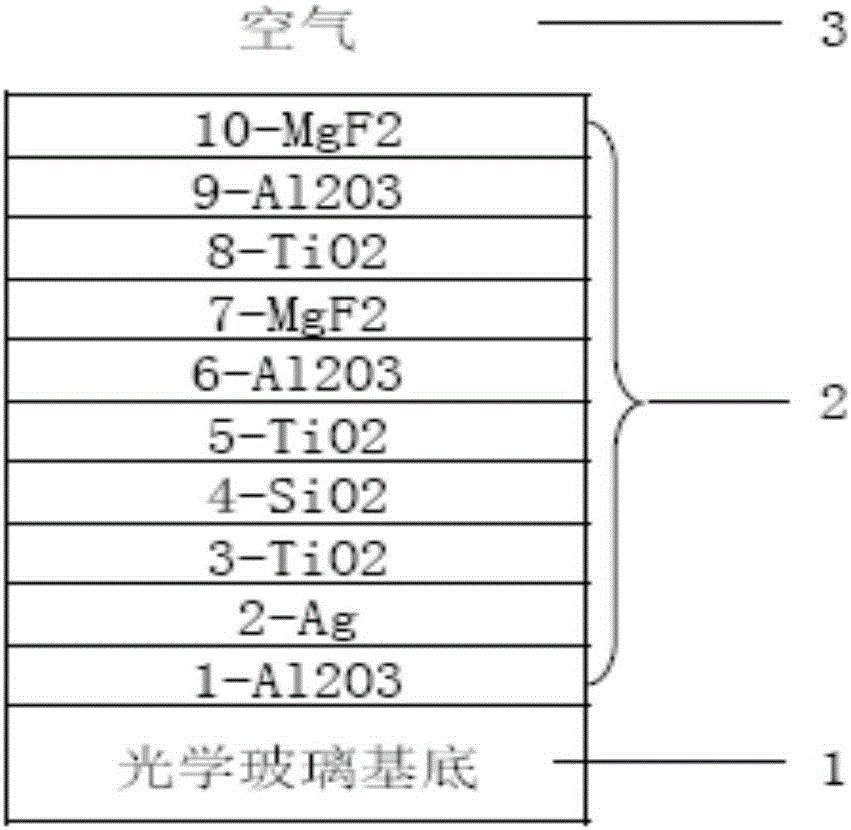

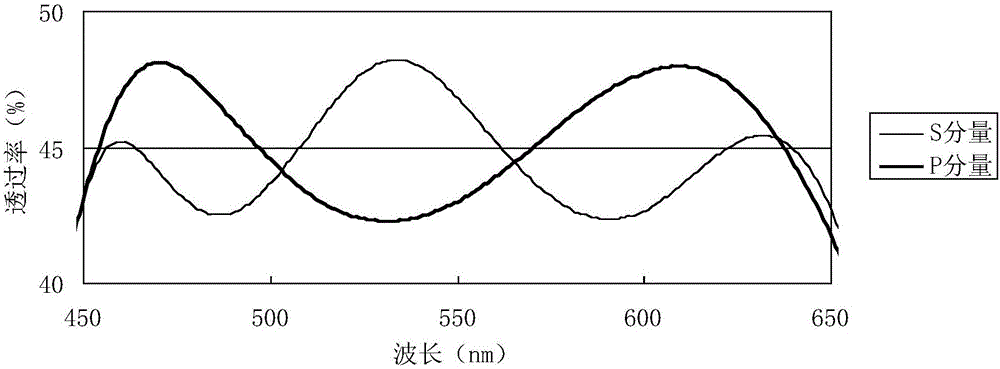

Embodiment 1

[0026] A visible wide-spectrum depolarization spectroscopic sheet, the spectroscopic sheet is composed of an optical glass substrate and a spectroscopic film deposited on the optical glass substrate, the spectroscopic film is composed of 10 film layers, and the thickness of the 10 film layers is sequentially : Layer 1, dielectric material Al 2 o 3 The thickness of the film layer is 4.99nm; the second layer, the metal material Ag film layer, the thickness is 25.6nm; the third layer, the dielectric material TiO 2 Film layer with a thickness of 32.9nm; the fourth layer, dielectric material SiO 2 Film layer with a thickness of 140.1nm; the fifth layer, dielectric material TiO 2 Film layer with a thickness of 25.2nm; the sixth layer, dielectric material Al 2 o 3 The thickness of the film layer is 110.5nm; the seventh layer, the dielectric material MgF2 film layer, the thickness is 130.7nm; the eighth layer, the dielectric material TiO 2 Film layer with a thickness of 13.4nm; t...

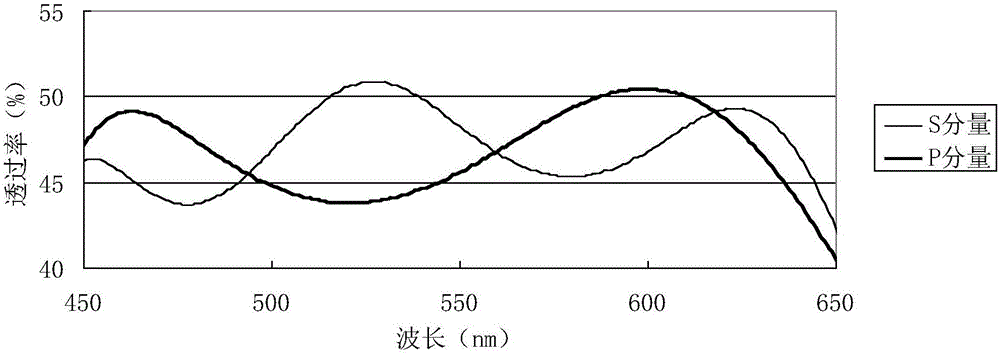

Embodiment 2

[0030] A visible wide-spectrum depolarization spectroscopic sheet, the spectroscopic sheet is composed of an optical glass substrate and a spectroscopic film deposited on the optical glass substrate, the spectroscopic film is composed of 10 film layers, and the thickness of the 10 film layers is sequentially : Layer 1, dielectric material Al 2 o 3 The thickness of the film layer is 5.0nm; the second layer, the metal material Ag film layer, the thickness is 25.3nm; the third layer, the dielectric material TiO 2Film layer with a thickness of 32.5nm; the fourth layer, dielectric material SiO 2 Film layer with a thickness of 138.7nm; the fifth layer, dielectric material TiO 2 Film layer with a thickness of 25.0nm; the sixth layer, dielectric material Al 2 o 3 The thickness of the film layer is 109.4nm; the seventh layer, the dielectric material MgF2 film layer, the thickness is 129.4nm; the eighth layer, the dielectric material TiO 2 Film layer with a thickness of 13.3nm; the...

Embodiment 3

[0034] A visible wide-spectrum depolarization spectroscopic sheet, the spectroscopic sheet is composed of an optical glass substrate and a spectroscopic film deposited on the optical glass substrate, the spectroscopic film is composed of 10 film layers, and the thickness of the 10 film layers is sequentially : Layer 1, dielectric material Al 2 o 3 The thickness of the film layer is 5.1nm; the second layer, the metal material Ag film layer, the thickness is 25.8nm; the third layer, the dielectric material TiO 2 Film layer with a thickness of 33.2nm; the fourth layer, dielectric material SiO 2 Film layer with a thickness of 141.5nm; the fifth layer, dielectric material TiO 2 Film layer with a thickness of 25.5nm; the sixth layer, dielectric material Al 2 o 3 The thickness of the film layer is 111.6nm; the seventh layer, the dielectric material MgF2 film layer, the thickness is 132.0nm; the eighth layer, the dielectric material TiO 2 Film layer with a thickness of 13.6nm; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com