Co3O4 nano-structure microbial composite material based on flaky flexible carbon cloth and preparation method and application thereof

A nanostructure and composite material technology, which is applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of long degradation time and microbial influence, and achieves simple preparation method, low cost, good quality The effect of adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (2) CC / Co 3 o 4 Preparation of complex

[0043] concentrated NH 3 ·H 2 O and EG were mixed under vigorous stirring. Then, Na 2 CO 3 Pour into the above mixture and stir further. After that, the Co(NO 3 ) 2 Add to the mixture and stir again. Then, the solution was transferred into a stainless steel autoclave, and the above-mentioned pretreated carbon cloth was inserted into the autoclave. The stainless steel autoclave was subjected to hydrothermal reaction for 8 hours. Subsequently, the carbon cloth-supported Co was removed from the autoclave 3 o 4 nanocrystals, rinsed with water and ethanol in turn, and dried in an oven. Finally, the precursors were calcined in air to obtain Co 3 o 4 Nanosheets, denoted as CC / Co 3 o 4 .

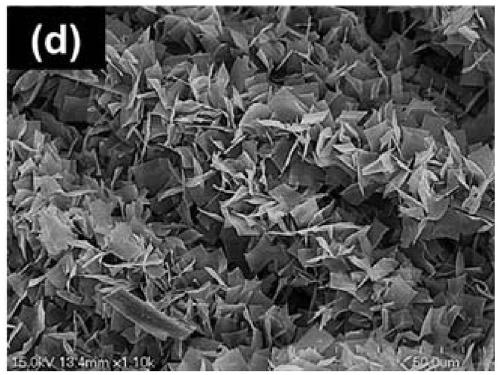

[0044] (3) load P. putida CC / Co 3 o 4 preparation of

[0045] Loading microorganisms into CC / Co 3 o 4 surface to obtain nanobiocomposites.

[0046] All raw materials of the present invention are commercially available, and the...

Embodiment 1

[0047] Example 1 The pretreatment of carbon cloth, the specific steps are as follows:

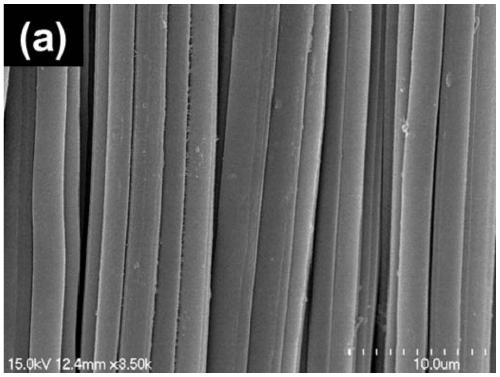

[0048] First, cut the carbon cloth into small pieces (1mm*1mm), and 2 SO 4 Continuous sonication in aqueous solution for 2 hours for cleaning, followed by H 2 SO 4 The treated carbon cloth was further cleaned by ultrasonic treatment with acetone, water and ethanol for 30 min each in sequence. Finally, the treated carbon cloth was treated with HNO 3 (8M) soaking treatment for 12 hours to obtain treated carbon cloth, which is used in Example 2. attached figure 1 It is the scanning electron microscope picture of the carbon cloth after pretreatment. It can be seen from the picture that the surface of the carbon cloth after treatment is relatively clean.

Embodiment 2

[0049] Example 2 CC / Co 3 o 4 The preparation of complex, specific steps are as follows:

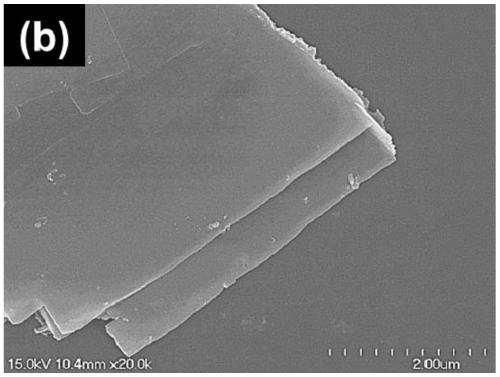

[0050] 12.5 mL concentrated NH 3 ·H 2 O (28 wt%) was mixed with 15 mL of EG (ethylene glycol) under vigorous stirring for 2 min. Then, 3.5 mL (1M) Na 2 CO 3 The aqueous solution was poured into the above mixture and stirred for 2 minutes. Afterwards, 5 mL of 1M Co(NO 3 ) 2 The aqueous solution was added to the mixture and stirred for another 20 minutes. Then, the solution was transferred to a 50 mL Teflon-lined stainless steel autoclave, and the above pretreated carbon cloth (0.5 g) was inserted into the autoclave, and the stainless steel autoclave was kept at 180 °C for 8 h , and let it cool naturally at room temperature. Subsequently, the carbon cloth-supported Co was removed from the autoclave 3 o 4 Nanocrystals were rinsed thoroughly with water and ethanol three times in turn, and dried in an oven at 60 °C for 12 h. Finally, the Co 3 o 4 Nanosheets, denoted as CC / Co 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com