A heating furnace control and combustion optimization method

A combustion optimization and heating furnace technology, applied in the direction of combustion control, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of furnace thermal efficiency decline, incomplete combustion, thermal pollution, etc., to ensure safety and stability, The effect of improving the safe service life and compensating for insensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The content of the invention will be further described below in conjunction with the accompanying drawings and embodiments.

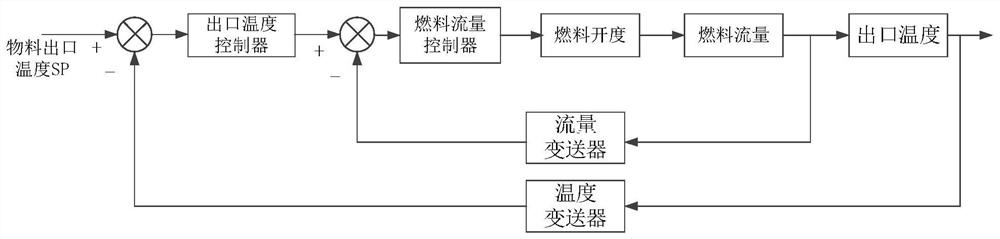

[0050] refer to figure 1 As shown, it is a block diagram of the medium outlet temperature control loop, and the specific steps are:

[0051] First of all, in the process of medium temperature control, cascade control is adopted.

[0052] Secondly, the outer loop uses the medium outlet temperature control loop as the main control loop, and the inner loop uses the fuel flow control loop as the secondary control loop.

[0053] Finally, when the temperature of the medium increases, the amount of fuel is reduced, and when the temperature of the medium decreases, the amount of fuel is increased. Aiming at the large hysteresis characteristics of the medium outlet temperature, the anti-lag MFA control strategy is adopted, and the non-disturbance switching of the control is realized through the state judgment conditions.

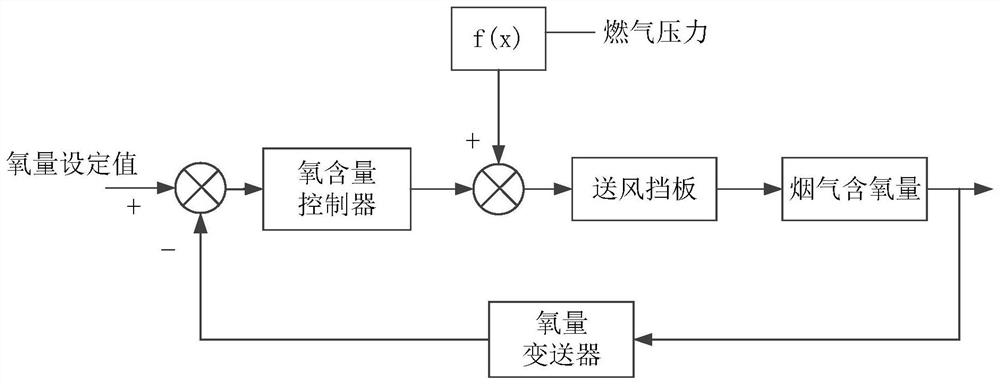

[0054] refer to figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com