Washing machine with dehydrating and collecting, cutting, and gear driving assemblies

A technology of gear transmission and washing machine, applied in the field of washing machine, can solve the problems of inconvenient maintenance, etc., and achieve the effects of low equipment production cost, simple structure, convenient operation and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

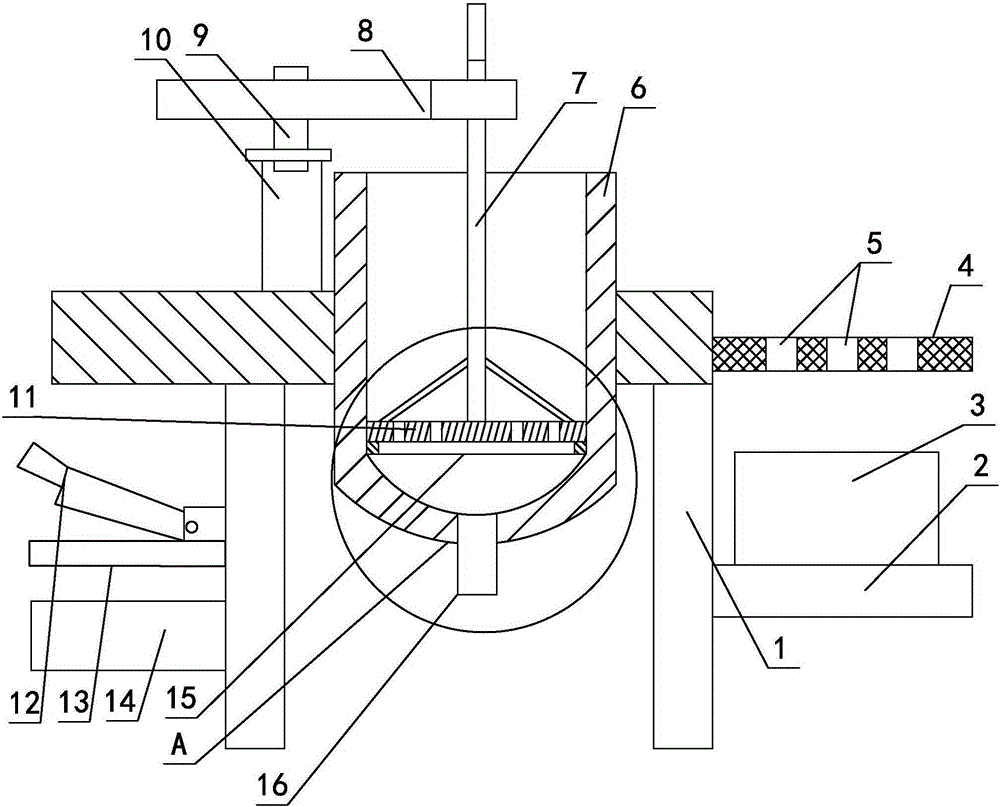

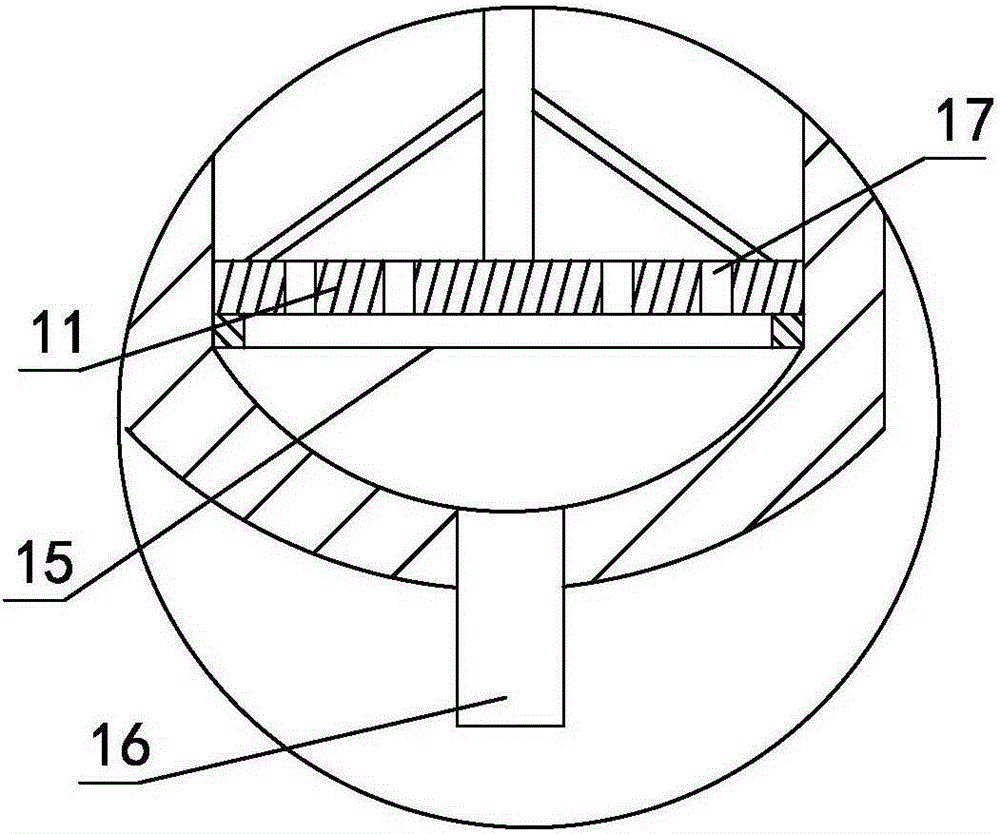

[0026] Such as figure 1 , figure 2 As shown, the cleaning machine with dehydration collection, cutting and gear transmission components includes a workbench 1, a cleaning bucket 6 is vertically installed on the workbench 1, and a drainage pipeline 16 is arranged at the bottom of the cleaning bucket 6. A lifting plate 11 that moves up and down is arranged horizontally inside, and a lifting rod 7 for moving the lifting plate 11 up and down is arranged on the top of the lifting plate 11. Several drainage holes 17 are opened on the lifting plate 11. In the lower left half of the workbench 1 A cutting knife 12 and a cutting board 13 that are mutually cut and matched are arranged horizontally, a waste collection tank 14 is arranged on the workbench 1 below the cutting board 13, and a gear mounting bracket 10 is installed on the workbench 1 near the left side of the cleaning bucket 6, The driving shaft 9 of power transmission is vertically arranged on the gear mounting bracket 10, ...

Embodiment 2

[0031] On the basis of Embodiment 1, the gap between the lifting plate 11 and the cleaning bucket 6 is changed to 20mm; the diameter of the drainage hole 17 is changed to 30mm; the power mechanism includes a hoist, and the hoist is installed through a bracket Above the workbench 1, the rope of the winch is connected with the lifting rod 7.

[0032] Others are the same as embodiment one.

Embodiment 3

[0034] On the basis of the first embodiment, the gap between the lifting plate 11 and the cleaning bucket 6 is changed to 15 mm; the diameter of the drainage hole 17 is changed to 20 mm.

[0035] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com