Impingement Flow Oil-Water Solubilization Method

A technology of impact flow reaction and impact box, which is applied in the field of oil fume purification, can solve the problems of secondary pollution of smoke and dust, manual cleaning, short contact time, etc., and achieve the effect of improving the emission purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

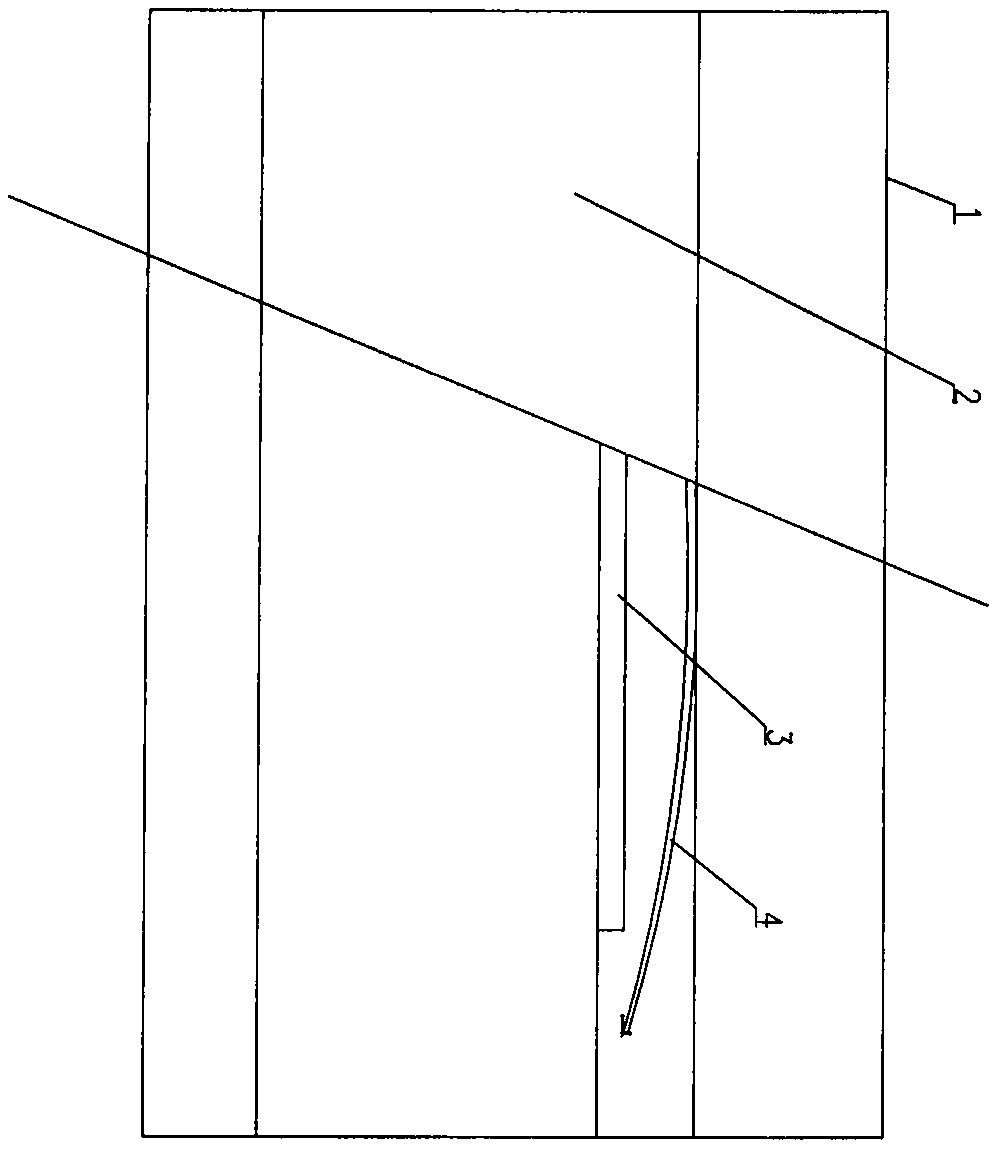

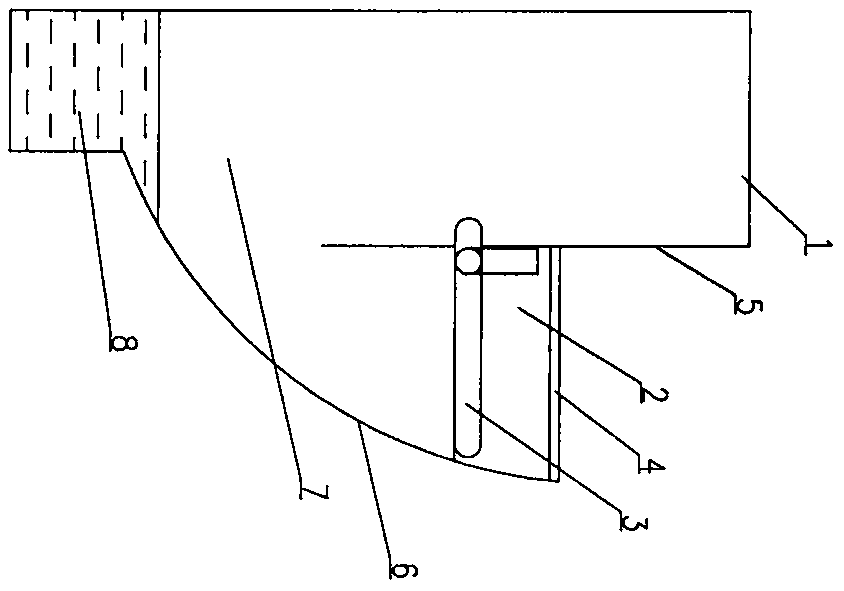

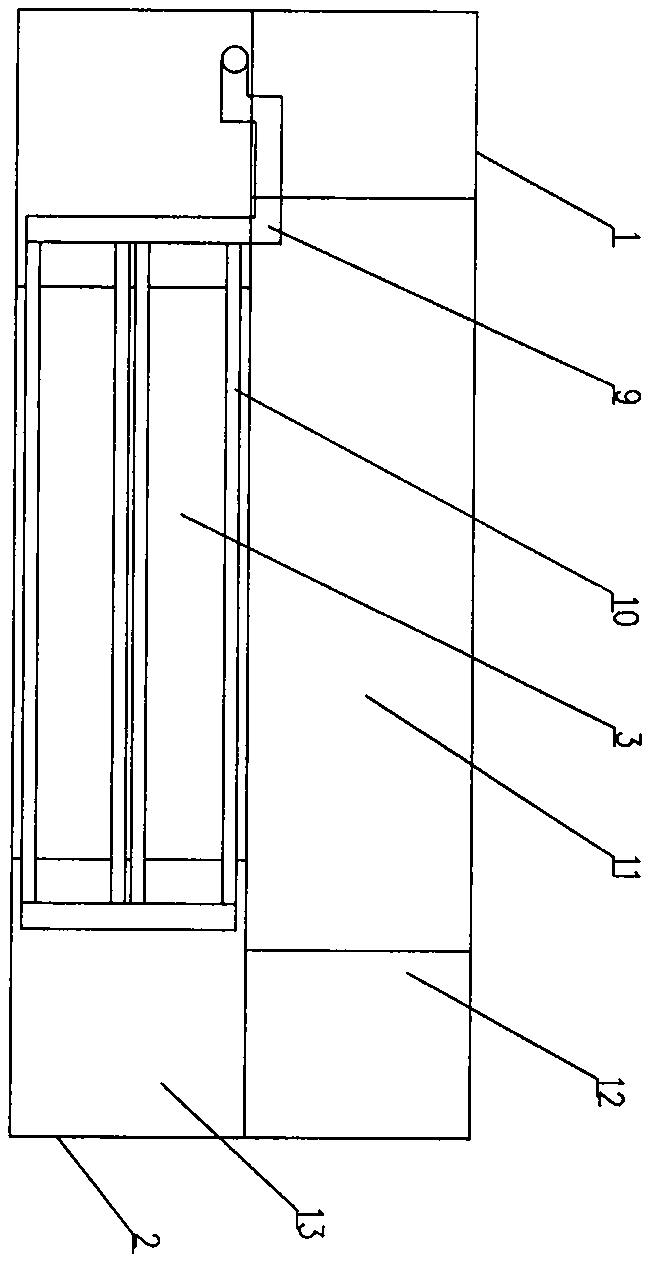

[0014] Examples such as Figure 1-4As shown, an impinging flow oil-water solubilization method is a technology for removing harmful substances in oil fume by using oil fume absorption accelerator and intelligent equipment. The intelligent equipment is equipped with an intelligent control system, impact flow reaction system, oil fume The absorption system and the oil fume temperature automatic monitoring system, the intelligent control system is provided with a control box, and the control box is equipped with a microcomputer control device 14, an oil fume absorption accelerator box 16, an accelerator stock liquid storage box 15 and a high-pressure water pump 17; The impinging flow reaction system is provided with an oil fume impact box 1, and an oil fume impact area 3 is arranged inside the oil fume impact box 1; the oil fume absorption system is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com