Method for preparing gold nano-flowers

A nanoflower, gold preparation technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of narrow production material range, expensive reaction conditions, uncontrollable morphology, etc. The effect of analysis and design, simple preparation process, and regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

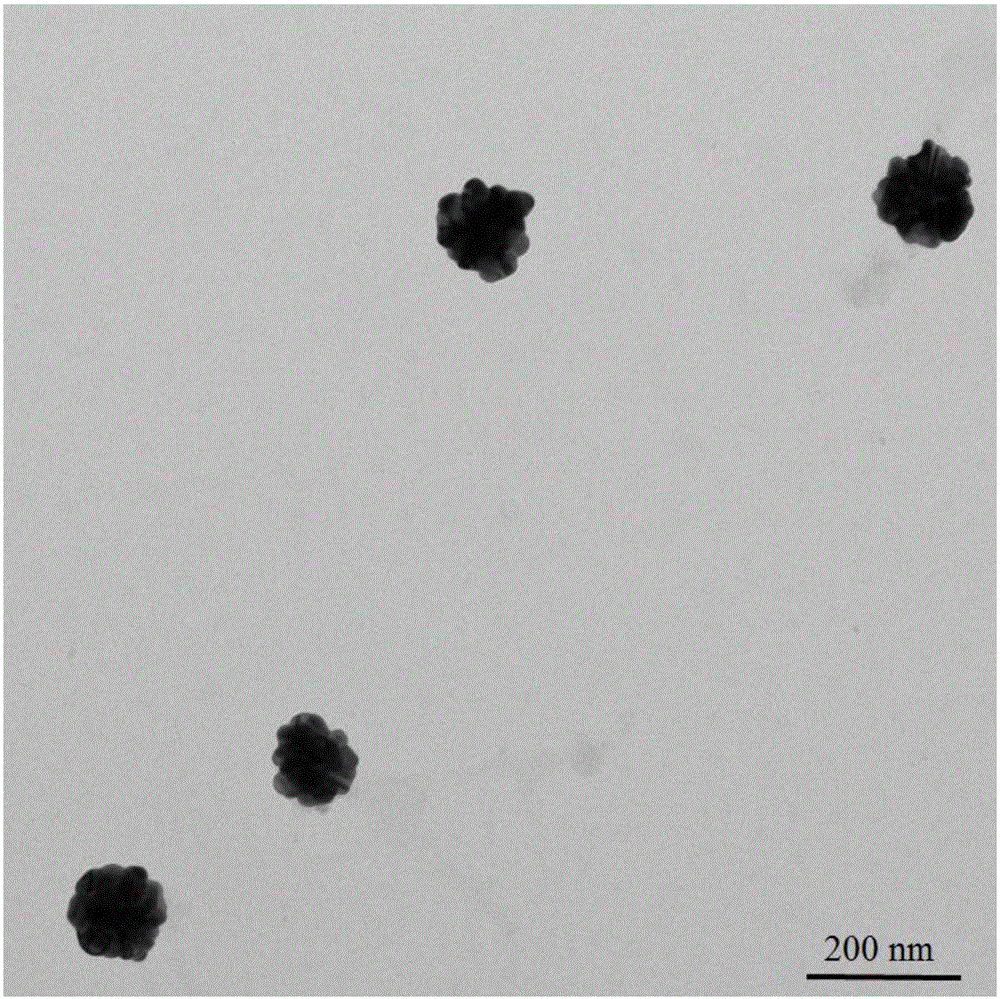

[0024] Take 0.57 mg of vapreotide acetate (Wuhan Dongkangyuan Technology Co., Ltd.), and dissolve it in 1 mL of hydrochloric acid solution with pH 2.0 to prepare a vapreotide acetate solution. Place the vapreotide acetate solution in a 60°C metal bath for 40 minutes, Then it was ultrasonically treated at 80 Hz for 30 s; 400 μL of vapreotide acetate solution after the metal bath was mixed with 400 μL of 5.0 mM gold trichloride aqueous solution (Tianjin Chemical Reagent Factory) and then placed in a constant temperature oscillator in a water bath, and the control speed was 110 rpm , and incubated at 23°C for 20 hours; finally, 50 μL of 8.0 mM sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) was added dropwise for reduction, the dropping speed was 2 drops / min, 25 μL / drop, and the temperature was 23°C , and reacted for 20 minutes to make it slowly change from light yellow to blue purple, and obtain vapreotide acetate-gold nanoflowers.

[0025] The m...

Embodiment 2

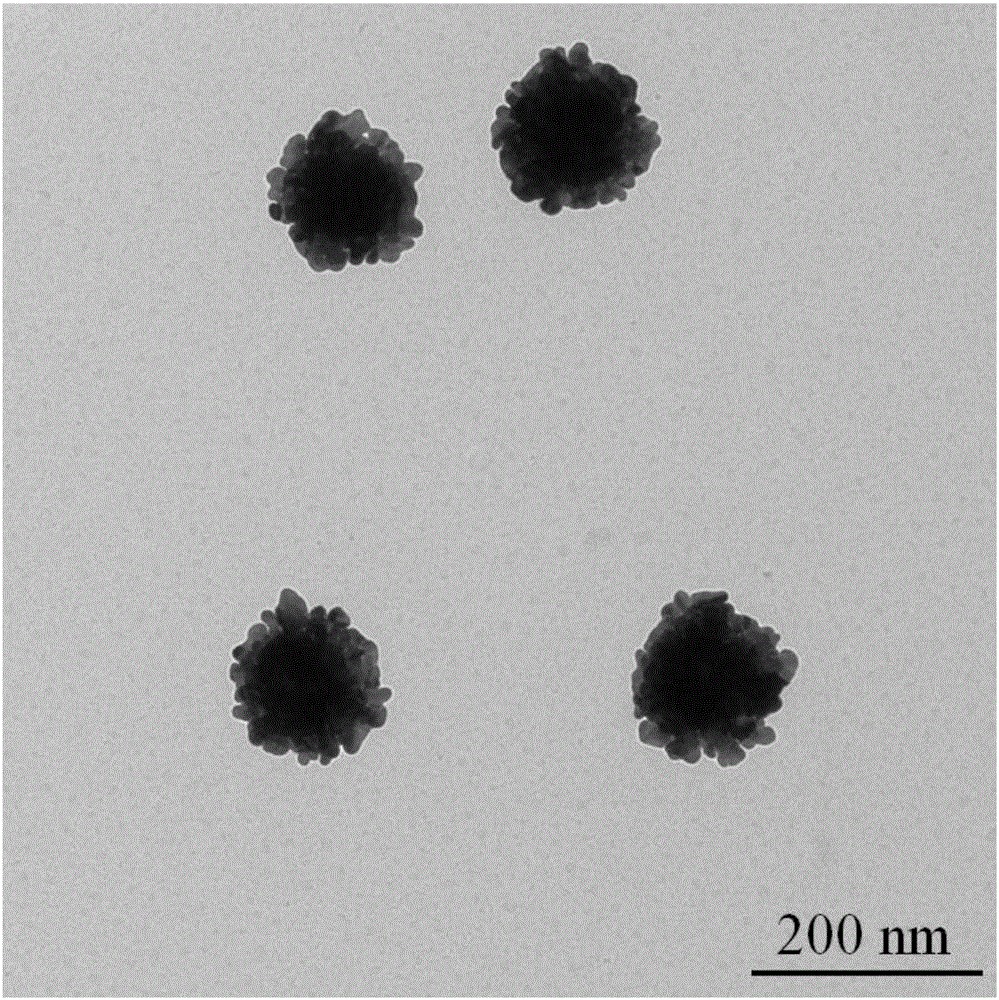

[0027] Take 0.68 mg of vapreotide acetate (Wuhan Dongkangyuan Technology Co., Ltd.), and dissolve it in 1 mL of hydrochloric acid solution with pH 2.5 to prepare a vapreotide acetate solution. Place the vapreotide acetate solution in a metal bath at 62°C for 42 minutes. Then it was ultrasonically treated at 80 Hz for 40 s; 400 μL of vapreotide acetate solution after the metal bath was mixed with 400 μL of 7.0 mM gold trichloride aqueous solution (Tianjin Chemical Reagent Factory) and then placed in a constant temperature oscillator in a water bath, and the control speed was 115 rpm , and incubated at 23°C for 21 hours; finally, 100 μL of 10.0 mM sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) was added dropwise for reduction, the dropping speed was 2 drops / min, 25 μL / drop, and the temperature was 23°C , and reacted for 22 minutes to make it slowly change from light yellow to blue-purple, that is, to obtain vapreotide acetate-gold nanoflowers.

...

Embodiment 3

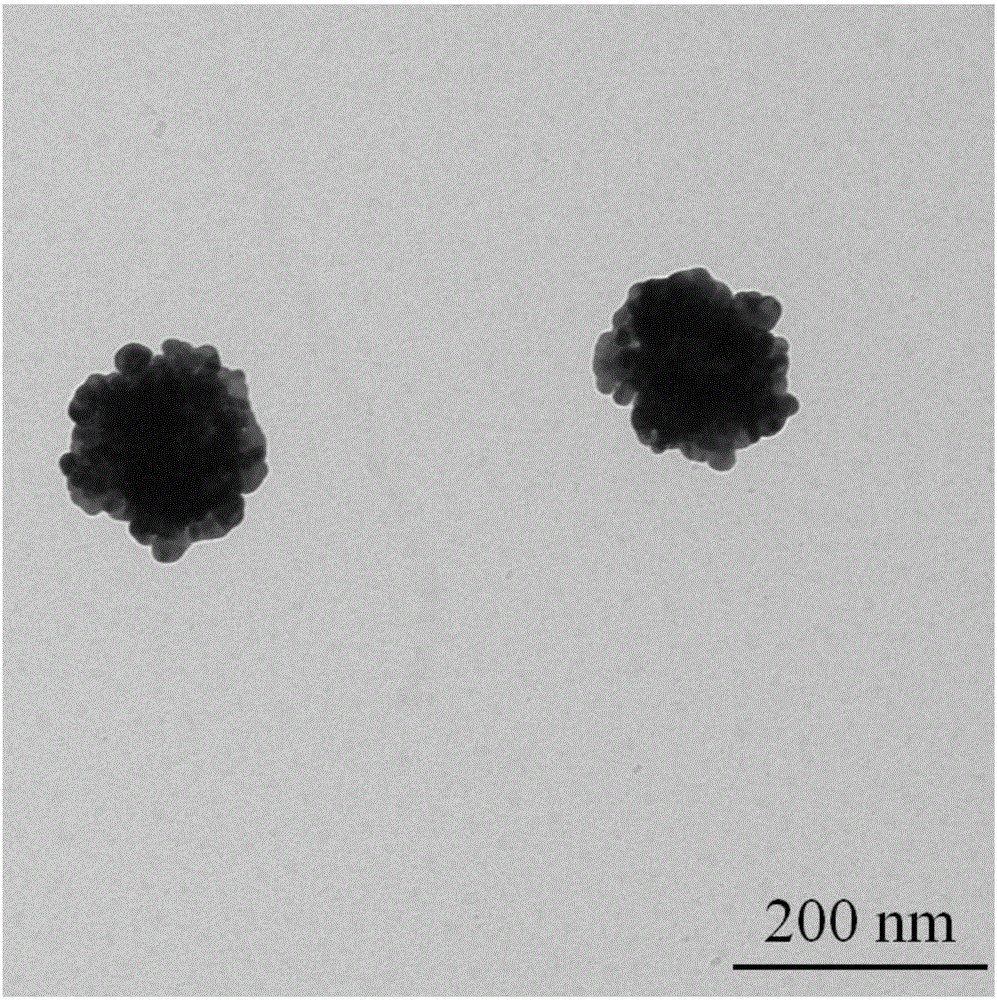

[0030] Take 0.79 mg of vapreotide acetate (Wuhan Dongkangyuan Technology Co., Ltd.), and dissolve it in 1 mL of hydrochloric acid solution with a pH of 3.0 to prepare a vapreotide acetate solution. Place the vapreotide acetate solution in a 64°C metal bath for 44 minutes, Then it was ultrasonically treated at 80 Hz for 50 s; 400 μL of vapreotide acetate solution after the metal bath was mixed with 400 μL of 9.0 mM gold trichloride aqueous solution (Tianjin Chemical Reagent Factory) and placed in a constant temperature oscillator in a water bath, and the control speed was 120 rpm. , and incubated at 23°C for 22 hours; finally, 150 μL of 12.0 mM sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) was added dropwise for reduction, the dropping speed was 2 drops / min, 25 μL / drop, and the temperature was 23°C , and reacted for 24 minutes to slowly change from light yellow to blue-purple, that is, to obtain vapreotide acetate-gold nanoflowers.

[0031] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com