Anti-ultraviolet and waterproof mobile phone hardening film

A hardening film and anti-ultraviolet technology, which is applied in the direction of chemical instruments and methods, lamination, coating, etc., can solve the problems of human eye visual fatigue, myopia, and ultraviolet rays that damage the skin, and achieve increased antistatic effect and strong shielding UV rays, effects of improving water resistance and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

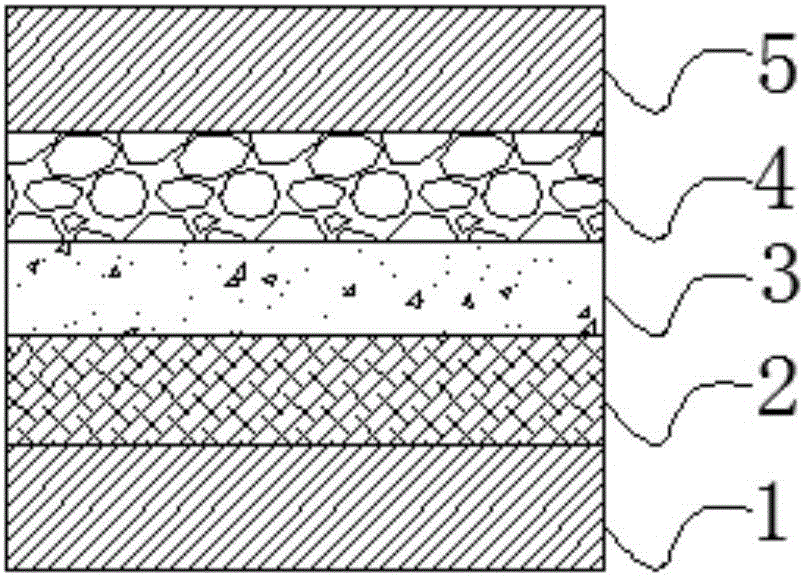

[0027] Embodiment 1: a kind of anti-ultraviolet, waterproof mobile phone hardening film, such as figure 1 As shown, it includes a film body, and the film body is sequentially provided with a first release film layer 1, a base layer 2, an anti-ultraviolet layer 3, a waterproof layer 4 and a second release film layer 5 from bottom to top. The composition raw materials of layer 3 are counted in parts by weight as follows: 20 parts of nano-titanium dioxide, 40 parts of benzotriazole, 15 parts of dibutyl phthalate, 14 parts of epoxy resin and 1 part of diluent, the waterproof layer 4 The composition raw materials are calculated in parts by weight as follows: 30 parts of polyurethane resin, 20 parts of butyl acetate, 10 parts of chloroalkyl ester and 1 part of fluorescent powder.

[0028] The diluent is at least one of ethylene glycol, propanol and isobutanol.

[0029] The phosphor is at least one of europium oxide phosphor, cerium oxide phosphor, alumina phosphor and barium oxide ...

Embodiment 2

[0036] Embodiment 2: a kind of anti-ultraviolet, waterproof mobile phone hardening film, such as figure 1 As shown, the rest are the same as in Example 1, except that the composition raw materials of the UV protection layer 3 are calculated in parts by weight as follows: 25 parts of nano-titanium dioxide, 50 parts of benzotriazole, 20 parts of dibutyl phthalate parts, 16 parts of epoxy resin and 2 parts of diluent, the composition raw materials of described waterproof layer 4 are counted by the following parts by weight: 35 parts of polyurethane resin, 45 parts of butyl acetate, 15 parts of chloroalkyl ester and 3 parts of fluorescent powder, The thickness of the waterproof layer 4 is 10 μm, the thickness of the ultraviolet protection layer 3 is 6 μm, the thickness of the base layer 2 is 12 μm, the first release film layer 1 and the second release film layer 5 The thickness is 13 μm.

Embodiment 3

[0037] Embodiment 3: a kind of anti-ultraviolet, waterproof mobile phone hardening film, such as figure 1 As shown, the rest are the same as in Example 1, except that the composition raw materials of the UV protection layer 3 are calculated in parts by weight as follows: 30 parts of nano-titanium dioxide, 60 parts of benzotriazole, 25 parts of dibutyl phthalate parts, 18 parts of epoxy resin and 3 parts of diluent, the composition raw materials of described waterproof layer 4 are counted according to the following parts by weight: 40 parts of polyurethane resin, 60 parts of butyl acetate, 20 parts of chloroalkyl ester and 5 parts of fluorescent powder, The thickness of the waterproof layer 4 is 20 μm, the thickness of the ultraviolet protection layer 3 is 10 μm, the thickness of the base layer 2 is 15 μm, the first release film layer 1 and the second release film layer 5 The thickness is 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com