Sandy kaolin based cordierite glass ceramic material and low-temperature preparation method thereof

A soil-based cordierite and glass-ceramic technology, which is applied in the field of low-temperature co-fired ceramic substrate materials, can solve the problems of increasing energy consumption, polluting the environment, reducing the utilization rate of sandy kaolin, and achieving energy saving and high flexural strength. , the effect of improving utilization and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

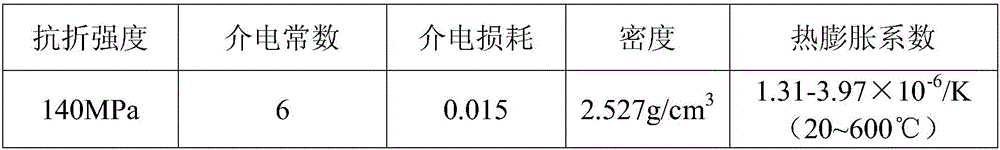

Embodiment 1

[0025] The chemical composition (mass percentage) of sandy kaolin:

[0026] SiO 2 —70-76%, Al 2 o 3 —14-20%, K 2 O—3-5%, Na 2 O—0-0.2%, CaO—0-0.1%, MgO—0-0.1%, Fe 2 o 3 —0.5-1%, MnO—0-0.02%, P 2 o 5 —0-0.02%, TiO 2 —0.3-0.5%;

[0027] The sandy kaolin meeting the requirements of the above components is first crushed, then wet-milled with a planetary mill to a mesh size below 100, and then dried to obtain sandy kaolin powder. Get sandy kaolin powder 30g, add analytically pure MgO, Al in the sandy kaolin powder 2 o 3 and SiO 2 , so that MgO, Al in raw materials 2 o 3 and SiO 2 The molar ratio is 2.5:2:5, then add NH 4 h 2 PO 4 and H 3 BO 3 , such that P 2 o 5 +B 2 o 3 The mass percentage of the glass is 5-6%, fully mixed to prepare the raw material of the glass precursor;

[0028] Pour the raw material of the glass precursor into a corundum crucible, place the corundum crucible in a high-temperature furnace, keep it warm at 1550°C for 4 hours to fully me...

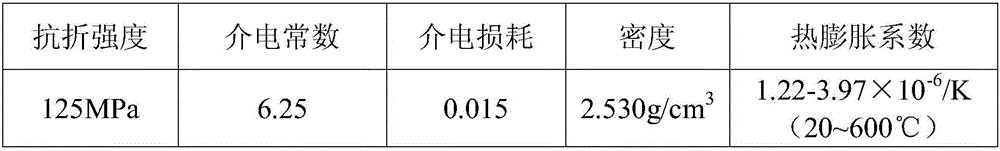

Embodiment 2

[0036] The chemical composition (mass percentage) of sandy kaolin:

[0037] SiO 2 —70-76%, Al 2 o 3 —14-20%, K 2 O—3-5%, Na 2 O—0-0.2%, CaO—0-0.1%, MgO—0-0.1%, Fe 2 o 3 —0.5-1%, MnO—0-0.02%, P 2 o 5 —0-0.02%, TiO 2 —0.3-0.5%;

[0038] The sandy kaolin meeting the requirements of the above components is first crushed, then wet-milled with a planetary mill to a mesh size below 100, and then dried to obtain sandy kaolin powder. Get sandy kaolin powder 40g, add analytically pure MgO, Al in sandy kaolin powder 2 o 3 and SiO 2 , so that MgO, Al in raw materials 2 o 3 and SiO 2 The molar ratio is 2.3:2:5, then add NH 4 h 2 PO 4 and H 3 BO 3 , such that P 2 o 5 +B 2 o 3 The mass percentage is 5-6%, fully mixed to prepare glass precursor raw materials;

[0039] Pour the raw material of the glass precursor into a corundum crucible, place the corundum crucible in a high-temperature furnace, keep it warm at 1550°C for 5 hours to fully melt, take it out directly at...

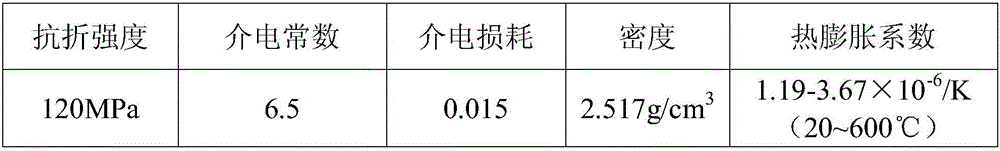

Embodiment 3

[0047] The chemical composition (mass percentage) of sandy kaolin:

[0048] SiO 2 —70-76%, Al 2 o 3 —14-20%, K 2 O—3-5%, Na 2 O—0-0.2%, CaO—0-0.1%, MgO—0-0.1%, Fe 2 o 3 —0.5-1%, MnO—0-0.02%, P 2 o 5 —0-0.02%, TiO 2 —0.3-0.5%;

[0049] The sandy kaolin meeting the requirements of the above components is first crushed, then wet-milled with a planetary mill to a mesh size below 100, and then dried to obtain sandy kaolin powder. Get sandy kaolin powder 50g, add analytically pure MgO, Al in the sandy kaolin powder 2 o 3 and SiO 2 , so that MgO, Al in raw materials 2 o 3 and SiO 2 The molar ratio is 2.1:2:5, then add NH 4 h 2 PO 4 and H 3 BO 3 , such that P 2 o 5 +B 2 o 3 The mass percentage is 5-6%, fully mixed to prepare glass precursor raw materials;

[0050] Pour the raw material of the glass precursor into a corundum crucible, place the corundum crucible in a high-temperature furnace, keep it warm at 1550°C for 6 hours to fully melt, take it out directl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com