Temperature-resistant salt-resistant monomer and polymer, and preparation method and application thereof

A temperature-resistant, salt-resistant, polymer technology, applied in chemical instruments and methods, sulfonic acid preparation, drilling compositions, etc., can solve problems such as poor temperature-resistant and salt-resistant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

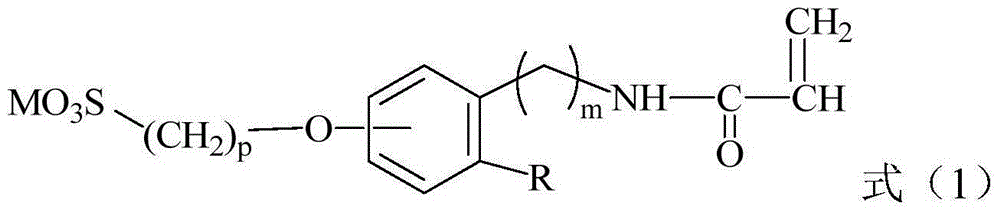

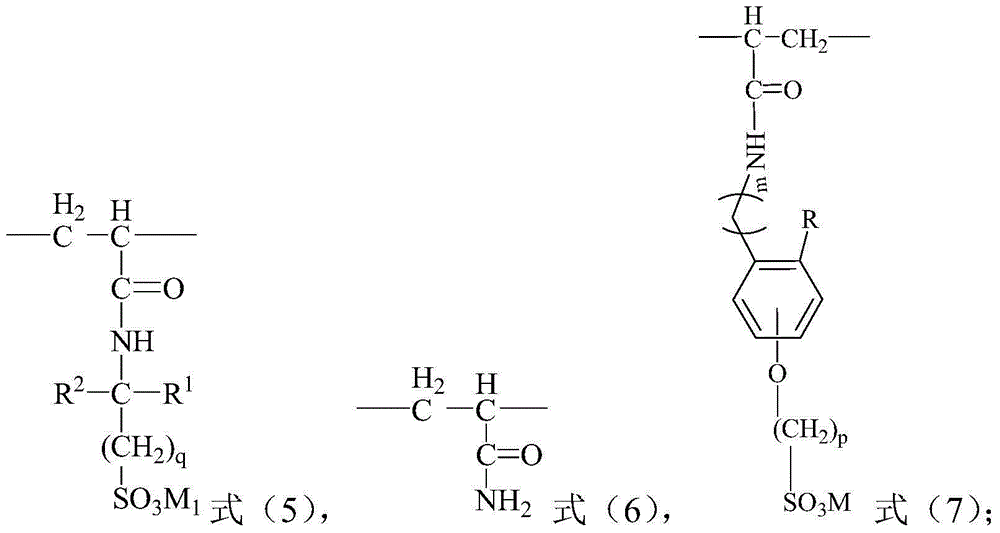

[0038] The present invention also provides a method for preparing a temperature-resistant and salt-resistant monomer, the method comprising the following steps:

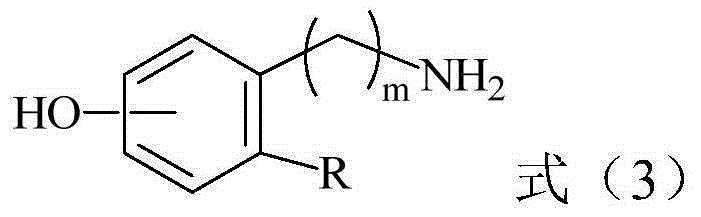

[0039] (1) Under amidation reaction conditions, the amine compound with the structure shown in formula (3) is contacted with acryloyl chloride;

[0040]

[0041] R is H, C1 -C 3 Alkylene, C 2 -C 3 The hydrocarbyl group with unsaturated double bonds or the absence; when R is C 1 -C 3 Alkylene or C 2 -C 3 When a hydrocarbon group with an unsaturated double bond is present, R and N atoms are bonded to form a ring; when R does not exist, the carbon atoms on the benzene ring connected to R are connected to N atoms; 0≤m≤3 and m is an integer;

[0042] (2) Under etherification reaction conditions, the product obtained in step (1) is contacted with haloalkylsulfonic acid; the general formula of the chloroalkylsulfonic acid is MSO 3 -(CH 2 )p 1 -X, X is halogen, p 1 is an integer of 1-3, and M is one of H, Li, Na...

Embodiment approach

[0053] According to a preferred embodiment of the present invention, the temperature-resistant and salt-resistant monomer is prepared by the following method:

[0054] (1) react the amine compound with the structure shown in formula (3) with acryloyl chloride overnight in an ice-water bath at 0°C under alkaline conditions, and then purify the reaction product;

[0055] (2) The product purified in step (1) is heated and refluxed with the haloalkylsulfonic acid and / or hexyllactone at 80°C under alkaline conditions for 2 hours, and the temperature-resistant product is obtained after purification. Anti-salt monomer.

[0056] The present invention has neither the method for purifying the reaction product of the amine compound and acryloyl chloride nor the method for purifying the reaction product of the product purified in step (1) with haloalkylsulfonic acid and / or hexyl sultone In particular, for example, purification can be carried out by extraction, recrystallization and the l...

preparation example 1

[0092] Preparation Example 1 is used to illustrate the temperature-resistant and salt-resistant monomer F1 provided by the present invention and its preparation method.

[0093] Add o-hydroxyaniline (10.9124g, 100mmol) into a dry three-necked flask, then add 250mL of anhydrous THF to dissolve, then add triethylamine (11.1301g, 110mmol), and stir at room temperature 25°C for 30min. Then the whole system was cooled to 0° C. with an ice-water bath, and acryloyl chloride (9.9611 g, 110 mmol) was slowly added dropwise while keeping the temperature constant. After the dropwise addition, naturally slowly return to room temperature 25°C and stir overnight. After the reaction was finished, water (100mL) was added dropwise to quench the reaction system, and then the reaction product was extracted with ether (75mL×3), and the reaction product was extracted with Na 2 SO 4 The organic phase was dried, spin-dried and then recrystallized (the recrystallization solvent was a mixture of n-he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com