Cell three-dimensional culture automatic generation device

A three-dimensional culture and generation device technology, which is applied in tissue cell/virus culture devices, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems of unscientific, lack, time-consuming and labor-intensive research models, and achieve experimental results. The process is safe and reliable, and the effect of meeting the needs of three-dimensional culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

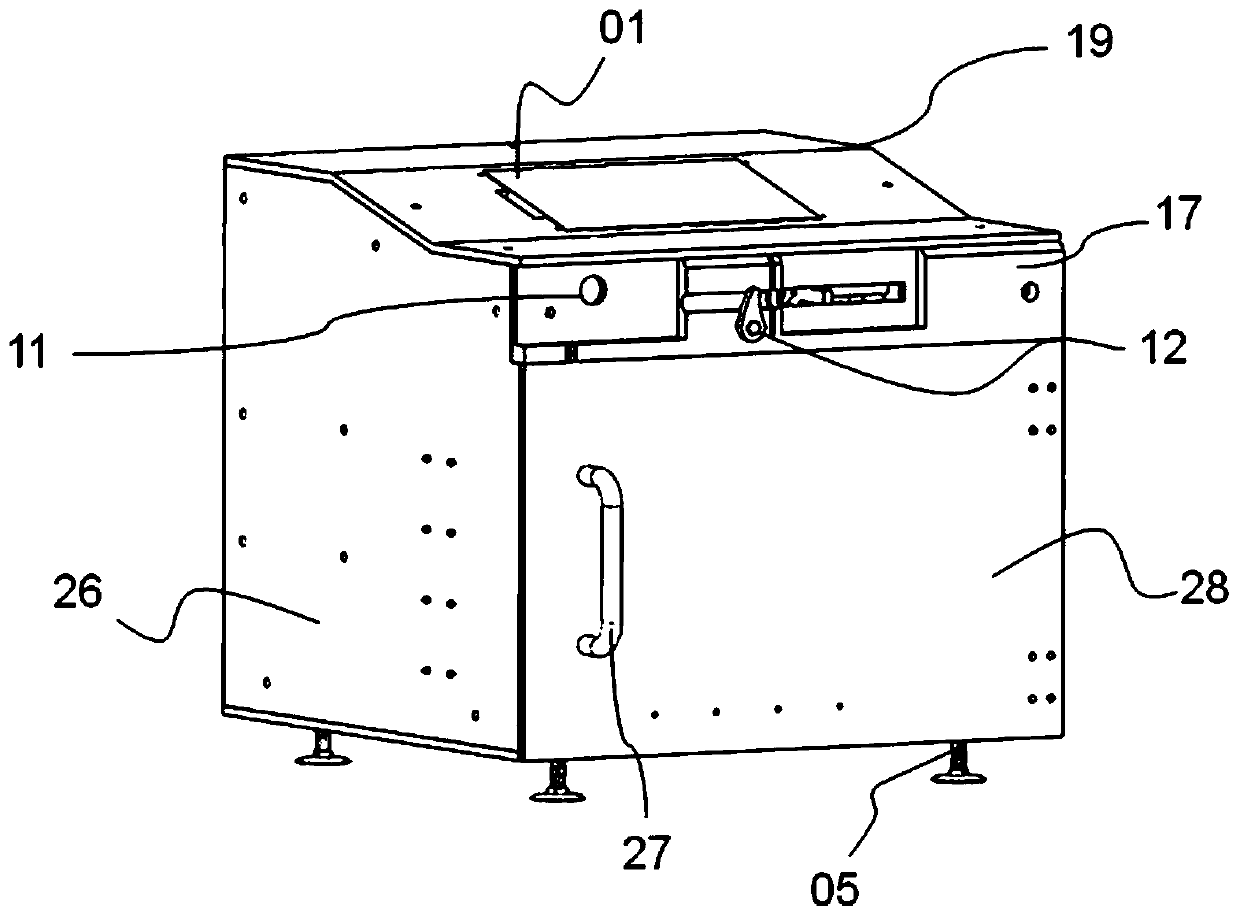

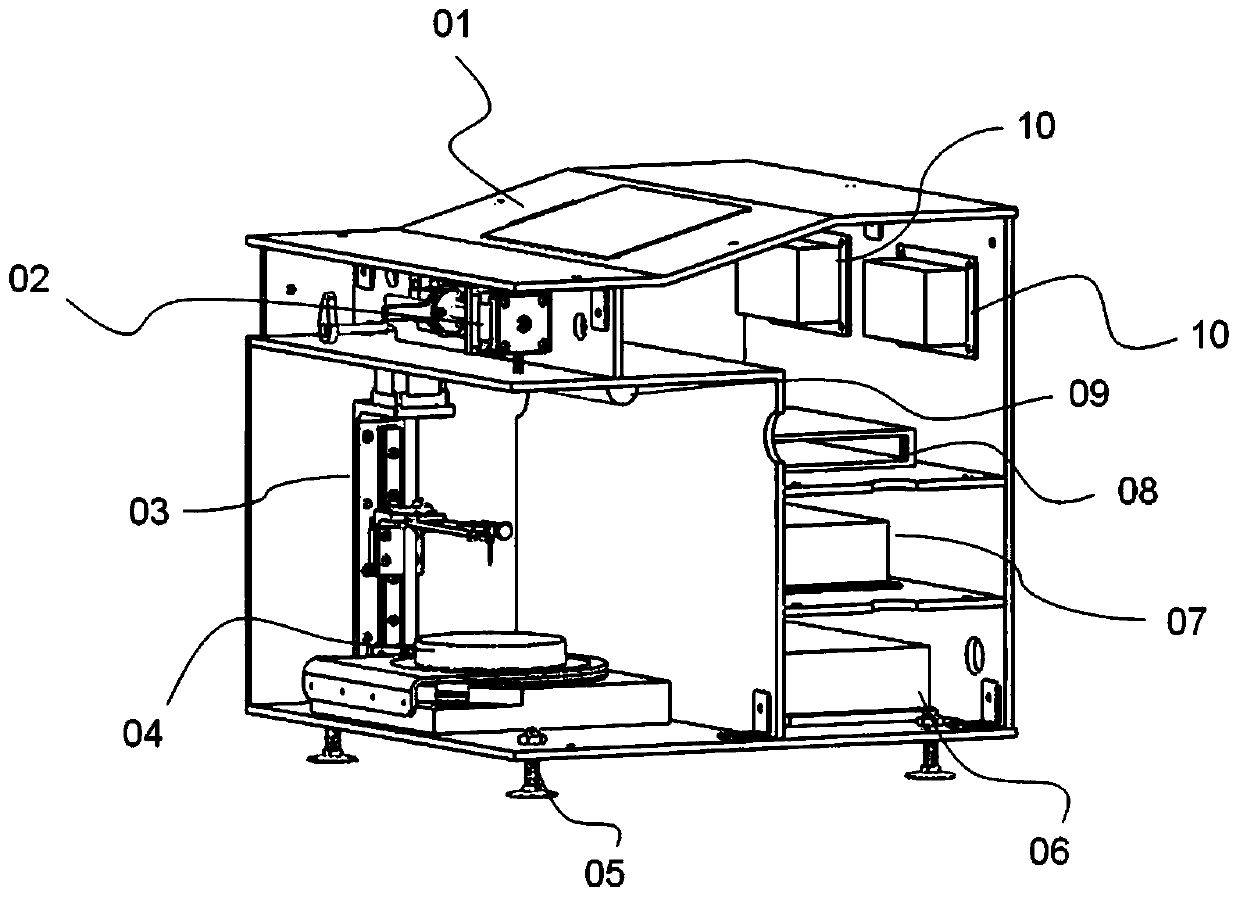

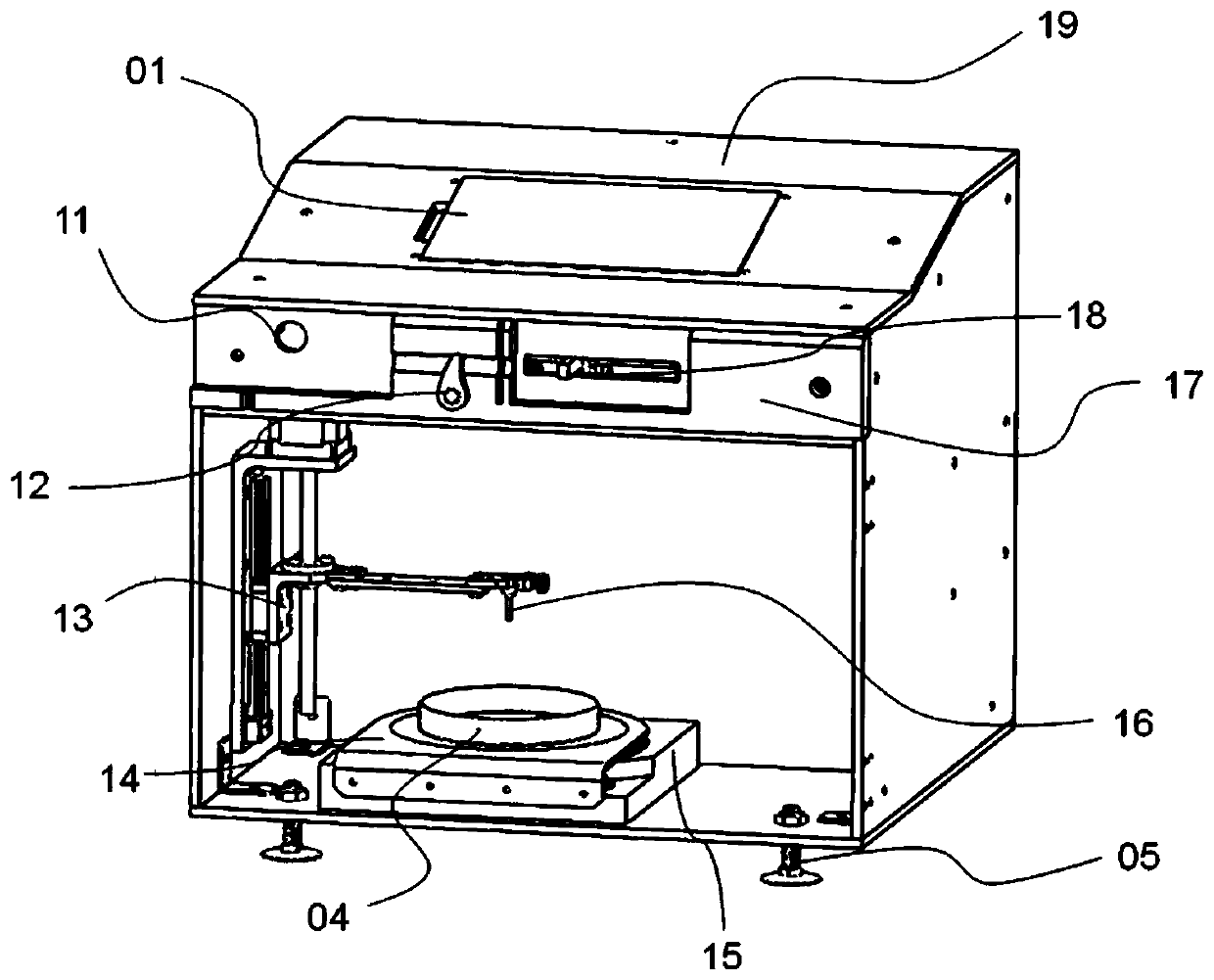

[0040] Such as Figure 1-6 As shown, the present invention provides a kind of automatic generating device for three-dimensional cell culture, including a casing with a working chamber and a storage room in isolation, the casing is composed of an instrument upper cover plate 19, a side wall plate 26, a rear panel, a bottom plate and a front door 28 The lower end of the bottom plate is supported by the base foot 05, the front door is provided with a handle 27, and the upper cover 19 of the instrument is provided with a slope. Specifically, the upper cover 19 of the instrument is in the shape of a broken line, and the slope is equipped with a touch screen 01. Groove for convenient touch display placement, composite ergonomics, touch screen 01 is set in the groove on the slope, convenient for observation and operation, the front door 28 of the casing is made of transparent insulating material to strengthen the insulation strength, and at the same time facilitate the operator Obser...

Embodiment 2

[0049] On the basis of Example 1, as Figure 6 As shown, a conductive support plate 14 is horizontally arranged on the inner side wall of the front door. After the front door is closed, the support plate 14 is just at the upper end of the negative plate 25, and the upper surface of the support plate 14 has petri dish grooves of different sizes. Placed on the support plate, the petri dish can be placed and taken out by opening and closing the door. The support plate has grooves for petri dishes of different specifications to ensure that the petri dish will not slip. The negative plate 14 is arranged at the bottom of the working chamber through an insulating plate 15 to enhance the insulation strength, while the negative plate 25 is connected to the ground wire to increase safety.

Embodiment 3

[0051] On the basis of Example 1, as figure 2 As shown, there is an ultraviolet germicidal lamp 09 on the upper end of the working room. The ultraviolet germicidal lamp is connected to the switching power supply and the single-chip microcomputer respectively. When starting up, the ultraviolet germicidal lamp automatically enters the sterilization program to reduce the pollution source in the working room. The sterilization program ends automatically and the machine enters the standby mode. state, the automated three-dimensional cell culture process is performed by controlling the touch screen.

[0052] The three-dimensional cell culture automatic generation device includes: the casing, which is hollow inside; the ultraviolet germicidal lamp, placed in the operating space, after starting up, the ultraviolet germicidal lamp automatically enters the sterilization program, automatically ends, and the machine enters the standby state; , this product is equipped with two stepping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com