Method, container and application for converting biomass material into soluble substances in one step

A biomass material and soluble technology, applied in the direction of electrolytic organic production, cells, electrolytic components, etc., can solve the problems of high cost and complicated lignin conversion process, and achieve the effect of no high temperature treatment, mild reaction conditions and high efficiency conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

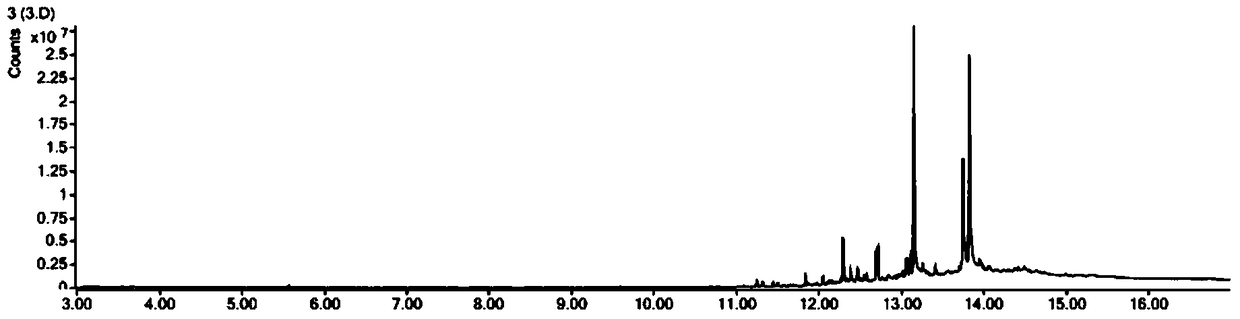

[0078] Utilize the above method, the present invention adopts following conditions to carry out experiment, current intensity: 0.3A; Reaction time is different; The volume concentration of the substance of NaCl: 0.4mol / L; The mass volume ratio of particle electrode and electrolyte: 2%; Mass volume ratio of lignin to electrolyte: 5%; sample was taken after reaction, extracted with ethyl acetate and n-hexane. Using GC-MS to analyze the types of products, the results of GC-MS showed that there were mainly two substances in the product, methyl palmitate and methyl octadecanoate. Since the product needs to be methylated before GC-MS, the actual product should be demethylated accordingly, so the main products of biomass conversion are palmitic acid and octadecanoic acid. The yield and conversion of each product were analyzed by GC-MS. The results of the gas phase detection chart are as follows: figure 1 Shown, product kind and transformation rate are as shown in table 1 and table ...

Embodiment 2

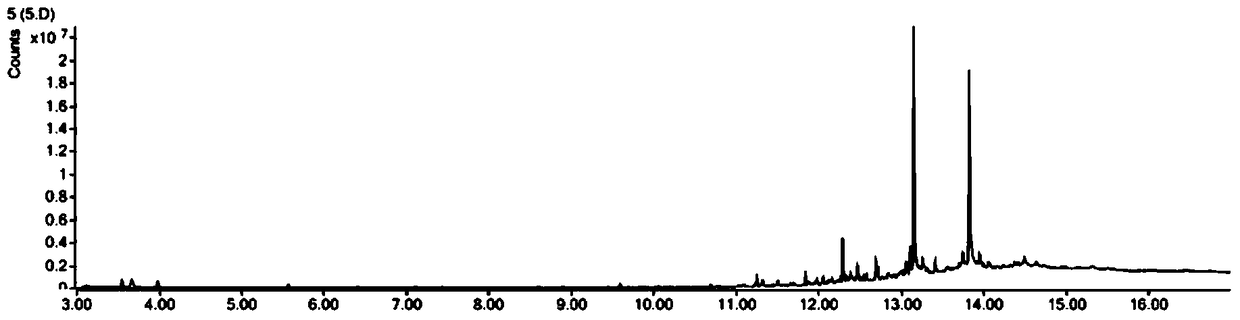

[0084] Utilize the above method, the present invention adopts following conditions to carry out experiment, electric current intensity: 0.3A; The amount concentration of the substance of NaCl: 0.2mol / L; Mass volume ratio: 5%; samples were taken after reacting for different times, and extracted with ethyl acetate and n-hexane. The yield and conversion rate of each product were analyzed by GC-MS, as shown in Table 3. The results of the gas phase detection chart are as follows: figure 2 shown.

[0085] The transformation rate of two kinds of products in the present embodiment of table 3

[0086]

[0087]

Embodiment 3

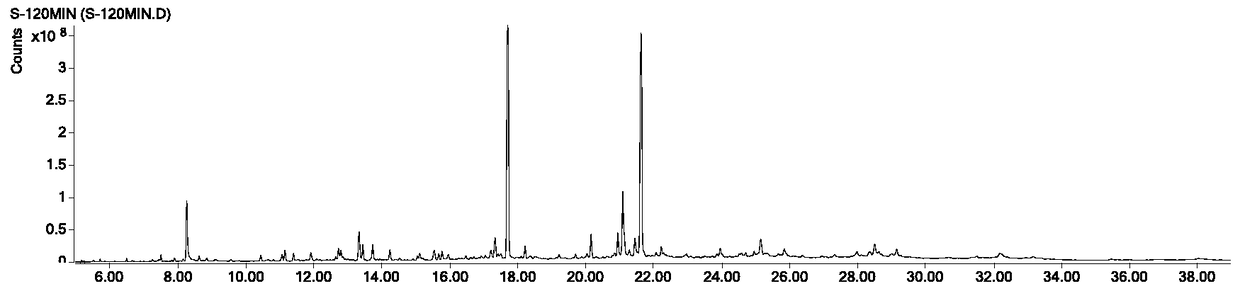

[0089] Utilize the above method, the present invention adopts following conditions to carry out experiment, current intensity: 0.5A; The amount concentration of the substance of NaCl: 0.1mol / L; Mass volume ratio: 5%; samples were taken after reacting for different times, and extracted with ethyl acetate and n-hexane. The yield and conversion rate of each product were analyzed by GC-MS, as shown in Table 4. The results of the weather monitoring map are as follows: image 3 shown.

[0090]The conversion rate of two kinds of products in the present embodiment of table 4

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com