Brick kiln for firing coal gangue bricks

A coal gangue and brick kiln technology, which is applied in the direction of furnace control devices, furnace types, waste heat treatment, etc., can solve the problems of inflexible control of kiln temperature, unstable product quality, and low processing efficiency, so as to make full use of waste heat and make full use of Energy and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

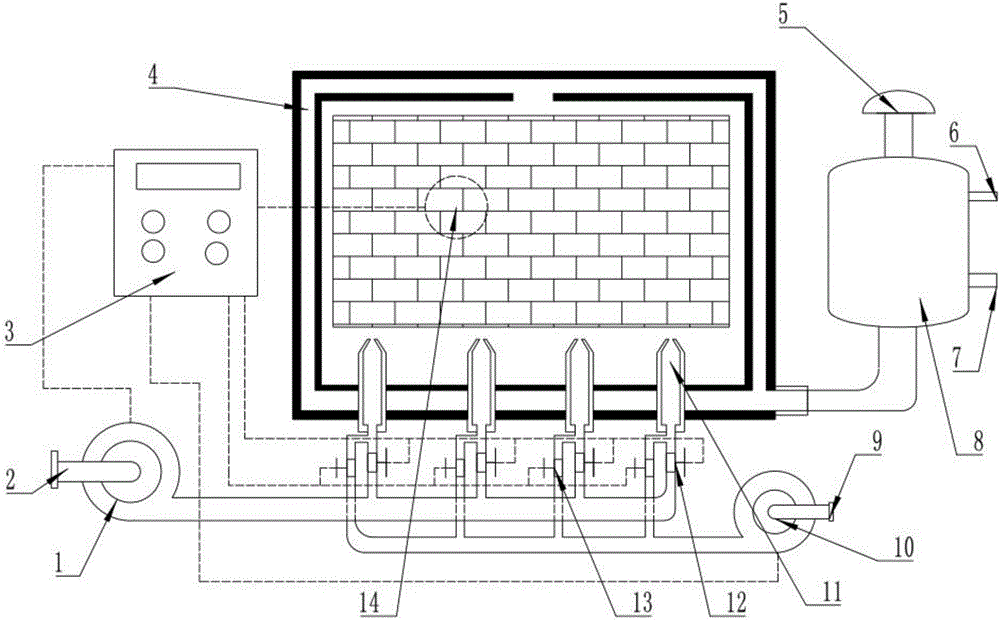

[0023] Such as figure 1 As shown, a brick kiln for firing coal gangue bricks is mainly composed of a firing furnace, a fuel control device and a waste heat collection device; the firing furnace is mainly composed of a gas booster 1, a gas inlet 2, and a kiln 4 , an air inlet 9, a blower 10, a burner 11, a gas valve 12, and an air valve 13; the kiln 4 is a cuboid hollow structure, the furnace wall of the kiln 4 has two layers, and a hollow flue is between the inner and outer layers; The burner 11 is arranged on the bottom of the kiln 4, and the flame nozzle of the burner 11 is arranged on the inside of the kiln 4, and the burner 11 passes through the furnace wall and is the same as the outside, and the burner 11 has two air inlets, and the burner 11 One air inlet is connected with gas valve 12, another air inlet of burner 11 is connected with air valve 13; The gas outlets are connected; the gas supercharger 1 is provided with a gas inlet 2 , and the blower 10 is provided with ...

Embodiment 2

[0030] On the basis of Example 1, this embodiment discloses a preferred structure of a brick kiln for firing gangue bricks, such as figure 1 As shown, the temperature sensor 14 is an optical temperature sensor. The optical temperature sensor can detect the temperature inside the kiln according to the infrared light emitted from the inside of the kiln.

[0031] Further, an air filter device is arranged on the air inlet 9 . The air filter device can reduce the dust entering the air inside the pipeline and improve the stability of the equipment.

[0032] Further, the gas valve 12 and the air valve 13 are electromagnetic brake valves. The solenoid valve can be controlled by the power supply, and the response is fast, which can improve the stability of the system. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com