Organic optical conductor

A technology of organic photoconductors and circumferential surfaces, applied in optics, electrical recording, instruments, etc., can solve the problems that affect the quality of production operations and output manuscripts, the difficulty of straightness control, and abnormal lines, etc. The effect of uniformity and small potential deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

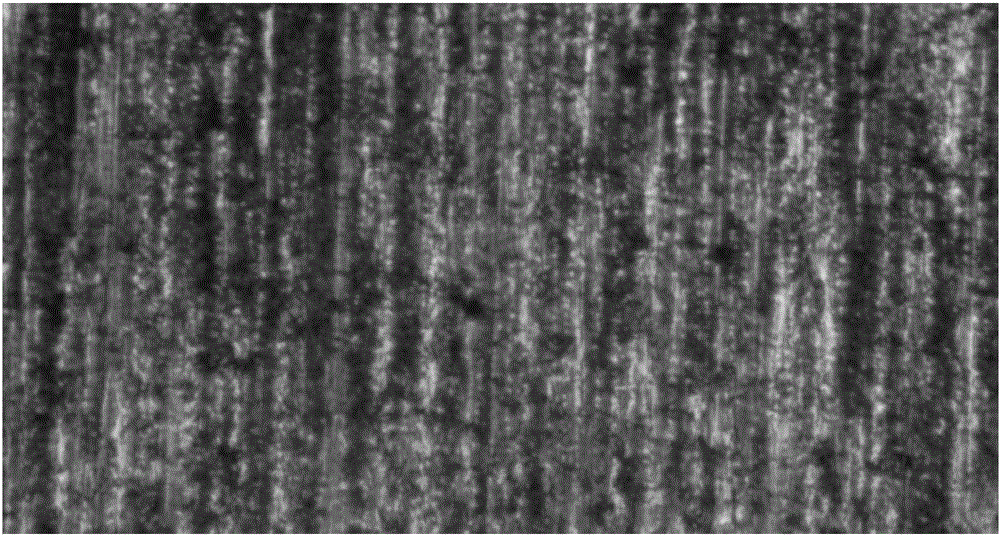

[0026] The present organic photoconductor consists of an aluminum base tube, such as figure 1 As shown, the circumferential surface of the aluminum-based tube is smooth and intermittent wear scars are formed on the circumferential surface, the width of the wear scars is ≤20 μm, and the length of the wear scars is ≤500 μm. The aluminum-based tube is processed by an abrasive belt grinder, the grain size of the abrasive belt is 60 mesh to 800 mesh, the rough and fine grinding or polishing is completed on the peripheral surface of the aluminum-based tube blank at one time, and the Rust, oil stains, spots, grooves, air bubbles and mechanical damage, the roughness is within 1.5μm.

Embodiment 2

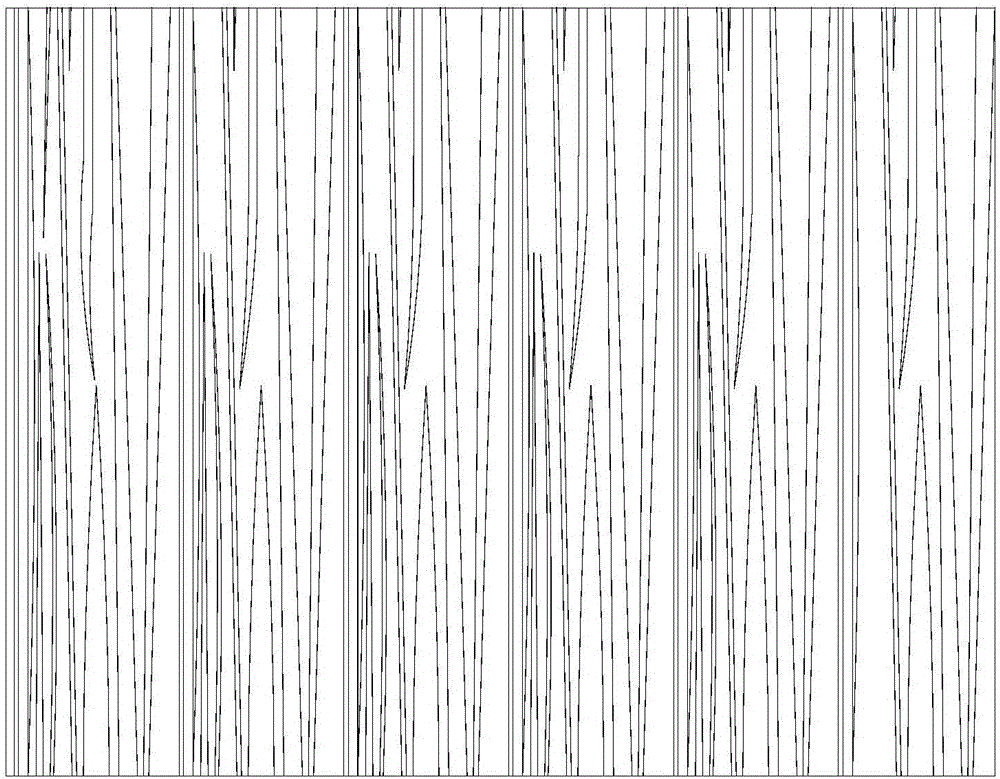

[0028] The present organic photoconductor consists of an aluminum base tube, such as figure 2 As shown, the circumferential surface of the aluminum base pipe is smooth and dislocation-distributed radial lines are formed on the circumferential surface, the width of the radial lines is ≤15 μm, and the length of the radial lines is ≤500 μm. The aluminum-based tube is processed by a grinding wheel grinder. The abrasive material is natural corundum, artificial corundum or artificial corundum. The particle size of the abrasive material ranges from 20 mesh to 360 mesh. The linear speed of the polishing wheel is 18-25m / s. The tube blank is subjected to rough grinding, medium grinding, and fine grinding to remove macroscopic defects on the circumferential surface of the aluminum-based tube, and the roughness is within 1.5 μm.

Embodiment 3

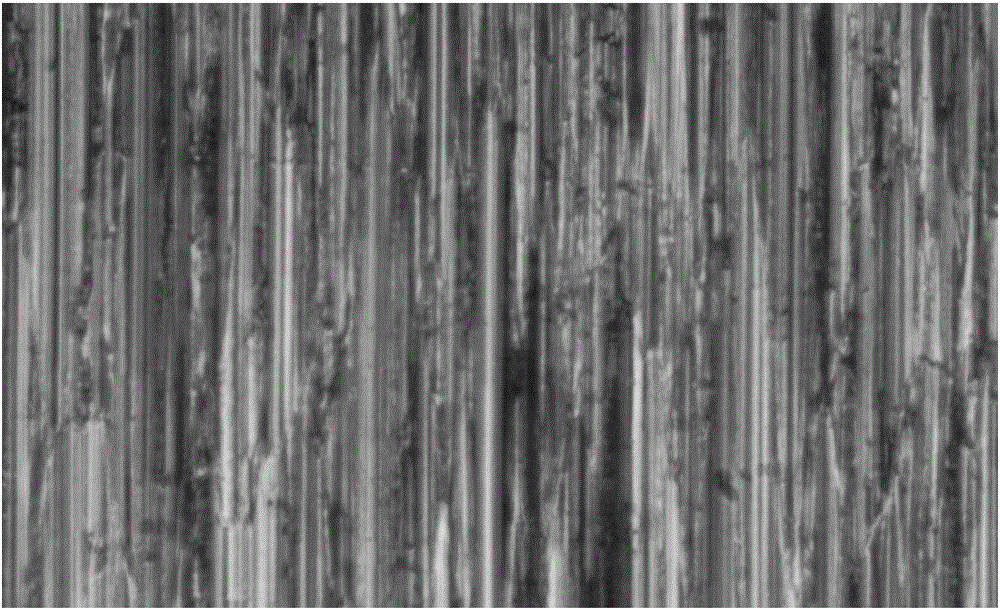

[0030] The present organic photoconductor consists of an aluminum base tube, such as image 3 As shown, the circumferential surface of the aluminum base tube is smooth and the circumferential surface is formed with an axial drawing line, the length of the drawing line is ≤ 500 μm, and the radial micro-fracture crystal structure caused by drawing, the micro-fracture crystal structure The length of the tissue is ≤ 100 μm. The aluminum-based tube is obtained by precision cold drawing. Before the precision cold-drawing, the aluminum ingot used to form the aluminum-based tube blank is subjected to 500-600°C for 8-12 hours of homogenization, and then is extruded through a split-flow combination die and quenched with strong wind. The hot-extruded tube is subjected to aging treatment at 150-300°C for 10-20 hours, and then precision cold-drawn. The concentricity and straightness of the precision cold-drawn tube are within 0.05mm, and the surface roughness of the circumference is within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com