Formation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve the problems that the electrical performance and reliability of semiconductor devices need to be improved, and achieve the effect of high ability and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

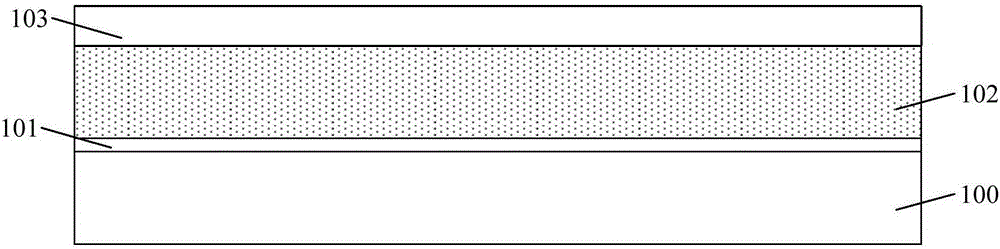

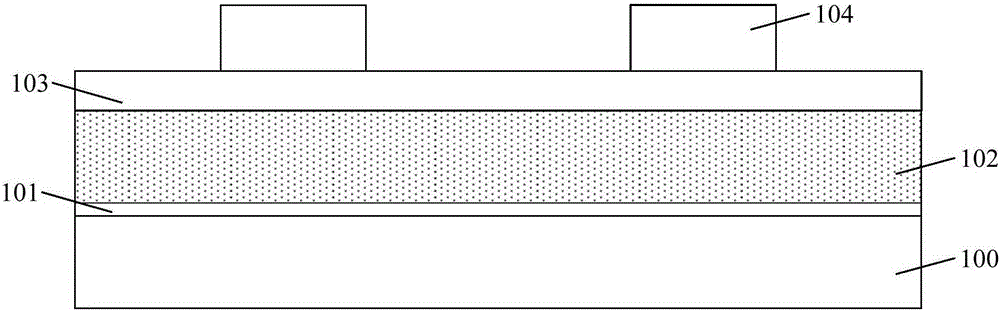

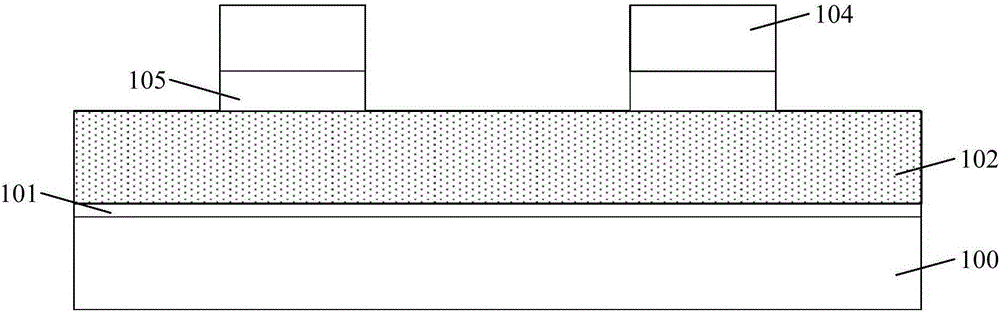

[0035] It can be seen from the background art that the electrical performance of semiconductor devices formed in the prior art needs to be improved.

[0036] It has been found through research that during the first patterning process of the initial hard mask layer, the etching gas used for the first patterning reacts chemically with the material of the initial hard mask layer to form a reaction by-product, and the etching gas It will also chemically react with the material of the first photoresist layer to form reaction by-products. Some of the reaction by-products will be taken away from the etching chamber with the flow of etching gas, and some of the reaction by-products will be taken away from the etching chamber under the action of their own gravity. The drops are attached to the first patterned hard mask layer, so that polymer impurities are formed on the first patterned hard mask layer and on the polysilicon layer around the first patterned hard mask layer . Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com