Formation method for metal interconnecting structure

A metal interconnection, metal technology, applied in the direction of semiconductor/solid-state device components, electrical components, circuits, etc., can solve the problems of RC delay, electromigration, the performance of metal interconnection structure needs to be improved, etc., to improve performance, reduce resistance, The effect of alleviating the RC delay problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

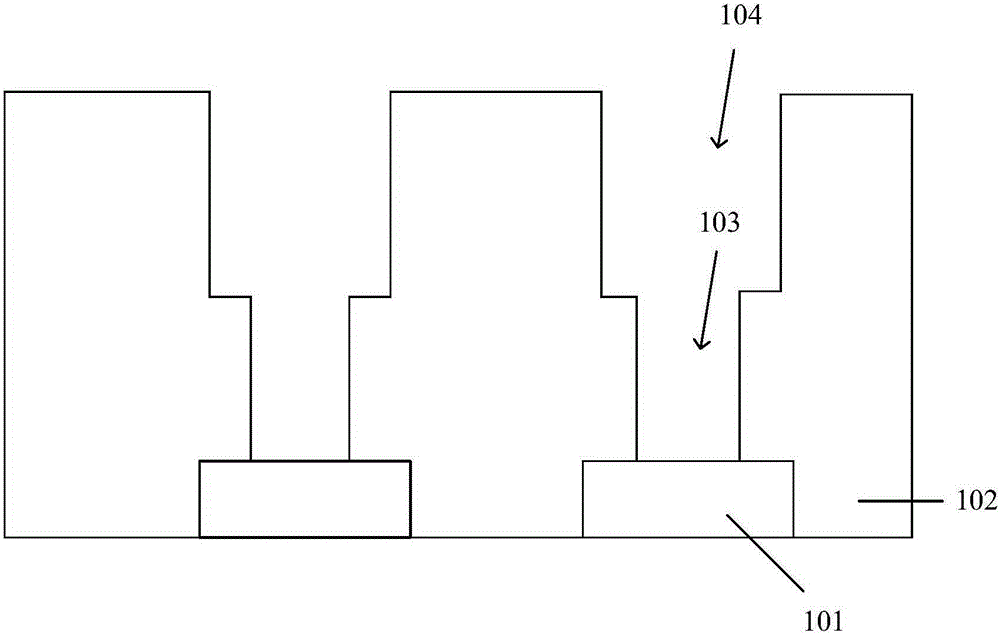

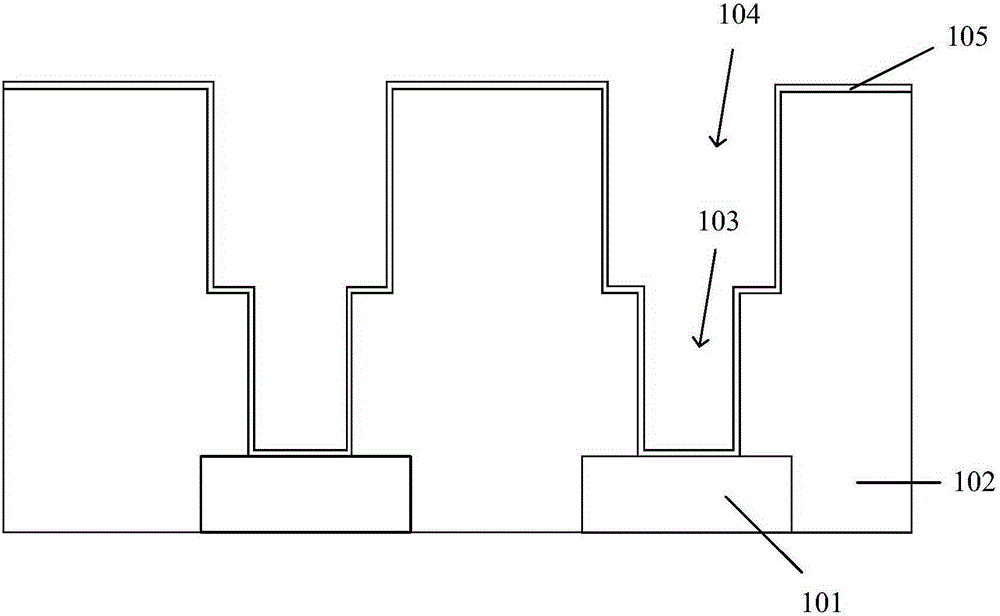

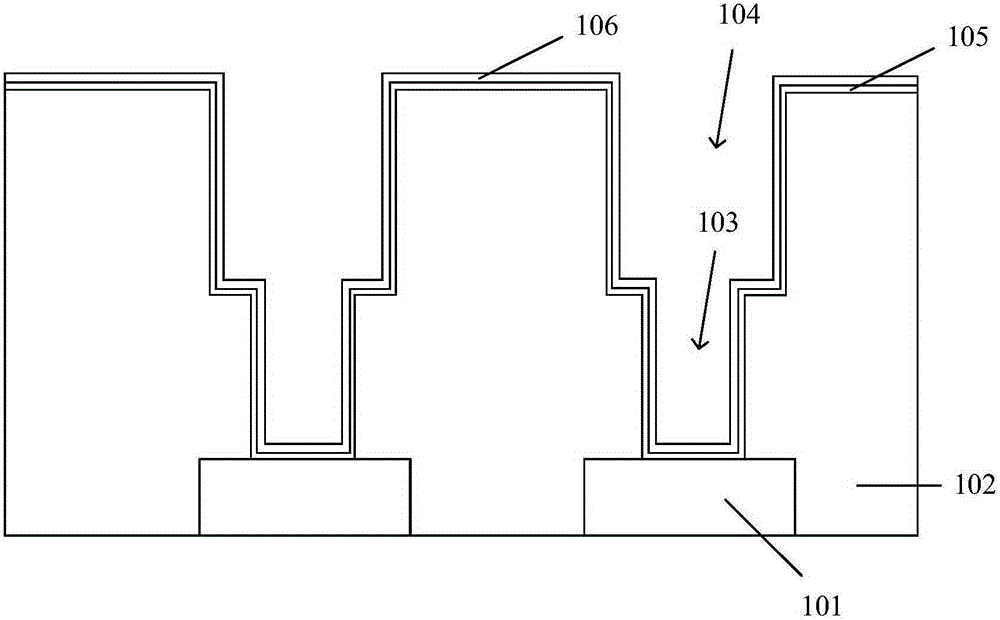

[0029] As mentioned in the background, in the existing semiconductor formation method, a metal nitride barrier layer is usually formed to prevent copper from diffusing into the dielectric layer. In the existing forming method, after forming the contact hole and the trench, the metal nitride barrier layer is directly formed. However, after the contact holes and trenches are formed, there will be many impurities on the surface of the front layer metal exposed at the bottom of the contact holes. These impurities are usually produced by the formation process of the contact holes and trenches. These impurities are usually nitrogen or oxygen elements. . When these impurities are present, the metal nitride barrier layer will cover them on the previous metal surface if the metal nitride barrier layer is formed directly. When subsequent layer metal is filled in the contact holes and trenches, these impurities still exist and cannot be eliminated. These impurities will lead to a decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com