Method for preparing biodegradable filling materials, product prepared by aid of method and application of product

A filling material and biological technology, applied in the field of materials, can solve the problems of slow degradation, easy to cause inflammation or foreign body granuloma, poor cell affinity, etc., to achieve slow degradation, environmentally friendly preparation process, and good tissue compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mixing the matrix material and the dispersed phase material at a mass ratio of 10:0 and dissolving them in hexafluoroisopropanol to obtain a polymeric organic solvent; the matrix material is polydioxanone;

[0037] (2) Dry the polymeric organic solvent at 60°C and a vacuum of 94KPa for 6h, remove the hexafluoroisopropanol, extrude it with a plastic extruder and freeze it quickly, at -20°C, the power is 45kW , the pulverization fineness is 60 mesh low-temperature pulverizers and low-temperature pulverization to obtain microspheres with a particle size of 250 μm.

Embodiment 2

[0039] (1) Mixing polydioxanone and polylactic acid in a mass ratio of 9:1 and dissolving them in dimethyl sulfoxide to obtain a polymeric organic solvent;

[0040] (2) Dry the polymeric organic solvent at 63°C and a vacuum of 95KPa for 5h, remove dimethyl sulfoxide, extrude it with a plastic extruder and freeze it quickly, at -60°C, the power is 55kW , the pulverization fineness is 400 mesh low-temperature pulverizers and low-temperature pulverization to obtain microspheres with a particle size of 38 μm.

Embodiment 3

[0042] (1) Mixing polydioxanone and polycaprolactone at a mass ratio of 8:2 and dissolving them in N,N-dimethylformamide to obtain a polymeric organic solvent;

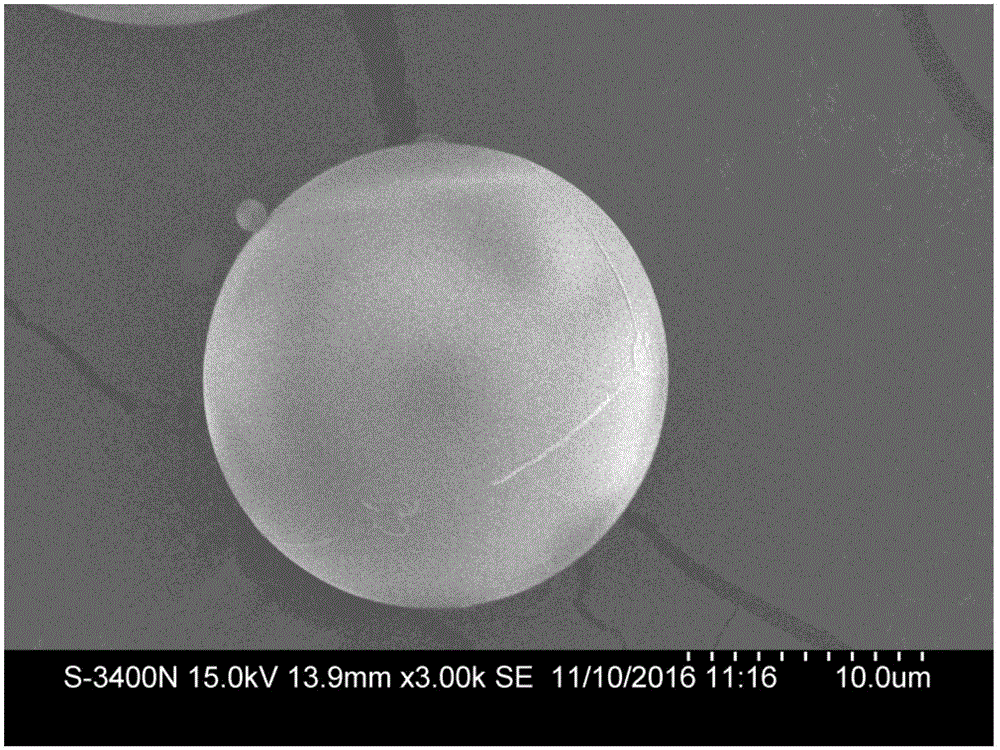

[0043] (2) Dry the polymeric organic solvent at 65°C and a vacuum of 96KPa for 4 hours, remove N,N-dimethylformamide, extrude it with a plastic extruder and freeze it quickly, and store it at -80°C , the power is 60kW, and the crushing fineness is 800 mesh low-temperature pulverizers to pulverize at low temperature to obtain microspheres. The microspheres are magnified 3000 times under a scanning electron microscope, and the results are as follows figure 1 shown by figure 1 It can be seen that the size of the microspheres is 18 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com