Methane combustion catalyst, and preparation method and application thereof

A methane combustion and catalyst technology, which is applied in combustion methods, catalyst protection, chemical instruments and methods, etc., can solve problems such as high temperature and easy sintering, and achieve the effects of improving high temperature resistance, improving catalytic combustion performance, and avoiding overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides the preparation method of the methane combustion catalyst described in the above technical scheme, comprising the following steps:

[0031] (1) Mix tricobalt tetroxide precursor, templating agent, polyvinylpyrrolidone and hydrogen peroxide in water, and perform hydrothermal reaction to obtain hydrothermal product;

[0032] (2) mixing the hydrothermal product obtained in the step (1) with a noble metal precursor and a silicon dioxide precursor, and reacting to obtain a combustion catalyst precursor;

[0033] (3) Calcining the combustion catalyst precursor obtained in the step (2) to obtain a combustion catalyst with a core-shell structure.

[0034] In the invention, the tricobalt tetroxide precursor, template agent, polyvinylpyrrolidone and hydrogen peroxide are mixed in water, and the hydrothermal reaction is carried out to obtain a hydrothermal product. In the present invention, the precursor of tricobalt tetroxide is preferably a solubl...

Embodiment 1

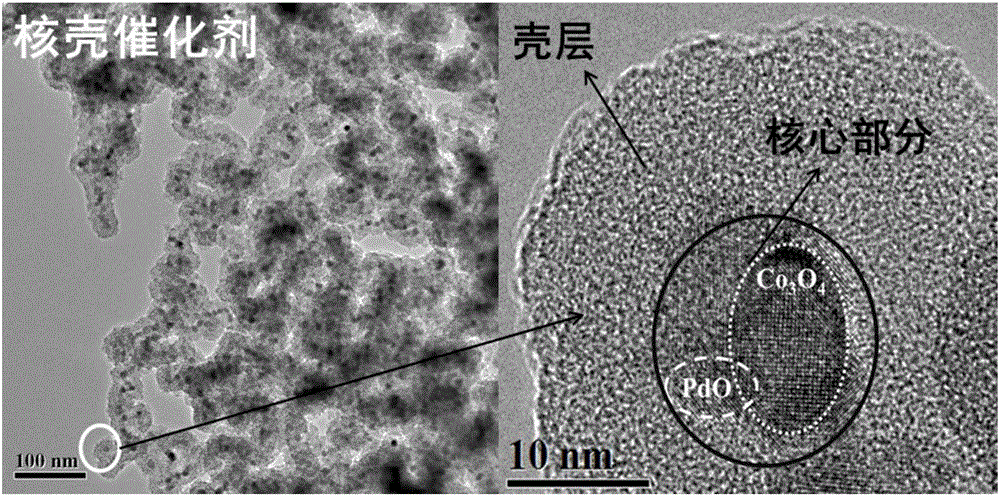

[0057] The core part of the core-shell catalyst of this embodiment is composed of 1.0wt% Pd, 30.0wt% CO 3 o 4 Composition, the rest of the mass is the shell part of SiO 2 .

[0058] The preparation method of this embodiment is:

[0059] (1) Mix 100ml of cobalt nitrate solution with molar concentration of 0.6mol / L and 20ml of 0.05mol / L hexamethylenetetramine aqueous solution in proportion, add 0.0006mol of polyvinylpyrrolidone and 30ml of 3wt% hydrogen peroxide aqueous solution , stirred at 40°C for 4h, and the stirring speed was 200rpm.

[0060] (2) 80ml mass fraction is the PdCl of 0.2wt%Pd 2 solution, directly add the solution described in (1), and continue to stir at 45° C. for 1 hour at a stirring speed of 400 rpm. Then, 128 ml of ethyl orthosilicate ethanol solution with a mass fraction of 50% was added dropwise to the above solution, and stirred at 50° C. for 4 h at a high rotation speed of 1200 rpm. Filter and wash, dry at 120°C for 6 hours, and high-temperature r...

Embodiment 2

[0063] The core part of the core-shell catalyst of this embodiment is made of 0.5wt% Pt, 20.0wt% CO 3 o 4 Composition, the rest is the shell part of SiO 2 .

[0064] The preparation method of this embodiment is:

[0065] (1) Mix 100ml of cobalt nitrate solution with molar concentration of 0.9mol / L and 45ml of 0.05mol / L hexamethylenetetramine aqueous solution in proportion, add 0.0003mol of polyvinylpyrrolidone and 50ml of 15% hydrogen peroxide aqueous solution , stirred at 50°C for 7h, and the stirring speed was 400rpm.

[0066] (2) 36ml mass fraction is the PtCl of 0.5%Pt 2 solution, directly add the solution described in (1), and continue to stir at 50° C. for 2 h at a stirring speed of 300 rpm. Then, 200 ml of ethyl orthosilicate ethanol solution with a mass fraction of 50% was added dropwise to the above solution, and stirred at 70° C. for 6 h at a high rotation speed of 850 rpm. Filter and wash, dry at 100°C for 6 hours, and calcinate at 800°C for 8 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com