Method for producing carbon material

A carbon material and municipal solid waste technology, applied in the field of carbon material production, can solve the problems of difficult to meet high standards, low product quality, and low comprehensive utilization of waste, and achieve improved carbonization efficiency, improved heating efficiency, and increased thermal efficiency. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

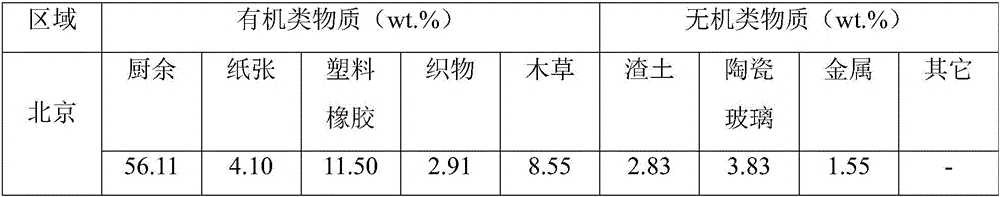

[0057] Municipal solid waste from Wuluju garbage compression and transfer station in Haidian District, Beijing was selected, and the composition of the garbage was tested as shown in Table 1 below:

[0058] Table 1: Composition of MSW

[0059]

[0060] Carry out high-temperature distillation and carbonization of the above-mentioned garbage through the following steps: After removing the dregs, glass, stones, ceramics and metals in the garbage through a garbage sorting machine such as a specific gravity sorting machine, put the garbage into the garbage transport device, and then put the garbage Pulverize; pass the garbage transport device through the high-temperature distillation carbonization device; take out the gas stream from the upper part of the high-temperature distillation carbonization device; pass the gas stream through the catalyst bed in gaseous form; condense and separate the effluent from the catalyst bed to obtain a liquid combustible material and water; carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com