Method for treating high-concentration wastewater produced by refining technology

A technology of high-concentration wastewater and treatment method, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Achieve the effect of energy saving and abnormal handling capacity, eliminating the need for sedimentation tanks and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

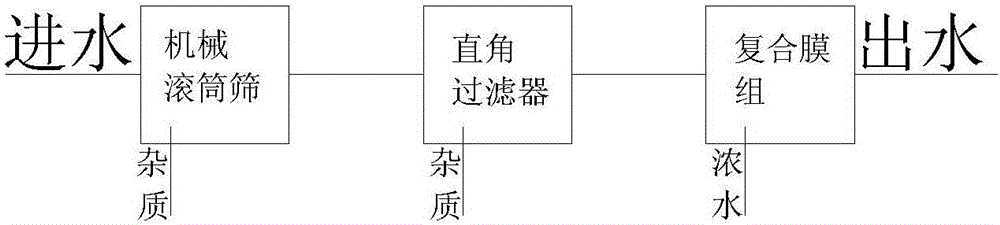

[0015] Such as figure 1 The high-concentration wastewater treatment method that shown a kind of scouring process produces, comprises the steps:

[0016] S1: First, the high-concentration wastewater enters the mechanical drum screen to remove the solid phase waste in the wastewater;

[0017] S2: Then, the wastewater from which solid phase waste has been removed flows into the circulating water tank, and then enters the flat composite membrane group treatment stack through the pump group to remove the slurry and oil in the wastewater, and finally completes the purification to form reusable water, which enters the recycling water Use the sink.

[0018] In some embodiments, S2 can also be: the waste water from which solid phase waste has been removed flows into the circulating water tank, and is sent to the RO membrane group through the pump group to remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com