Preparation method of carbon/carbon composite material beta-Y2Si2O7 whisker-toughened Y2SiO5/YAS glass-ceramic composite antioxidant coating

A technology of carbon composite material and anti-oxidation coating, which is applied in the field of preparing carbon/carbon composite material composite outer coating to achieve the effects of preventing the development of cracks, improving matching, and shortening the preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

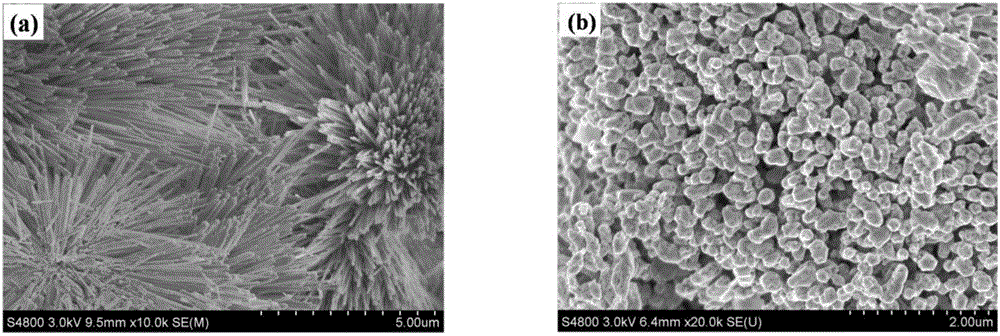

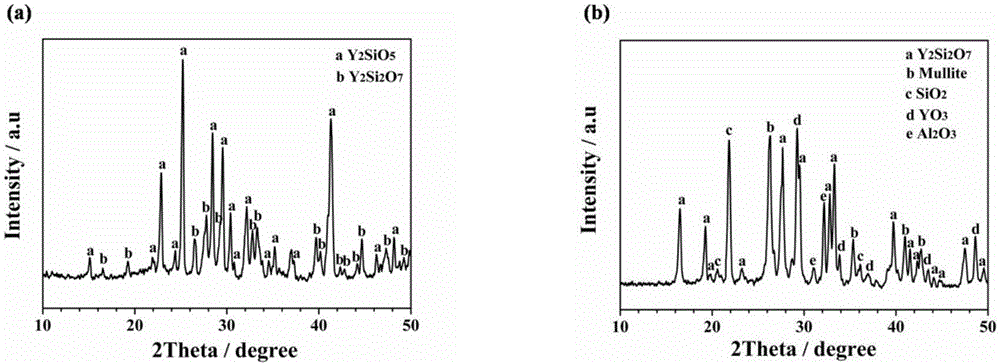

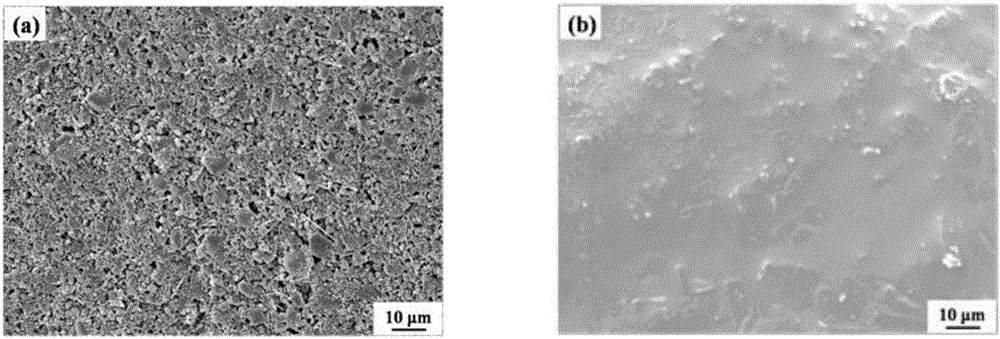

[0045] (1) First take an appropriate amount of Y 2 SiO 5 Powder, β-Y 2 Si 2 o 7 Whiskers, control the mass ratio of the two: β-Y 2 Si 2 o 7 Whiskers: 30wt%, Y2 SiO 5 Powder: 70wt%, dispersed in isopropanol, prepared into a suspension with a concentration of 30g / L, then put the suspension into an ultrasonic generator and vibrated for 10 minutes, took it out, put it into a magnetic rotor, and placed it on a magnetic stirrer Stir for 12h to obtain suspension A;

[0046] (2) Add iodine elemental substance to the suspension A to obtain a mixture, the concentration of iodine in the mixture is 3g / L, then place it on a magnetic stirrer to stir and heat, the stirring time is 2h, and the heating temperature is 60°C to obtain a solution B;

[0047] (3) Pour the suspension B into the hydrothermal kettle, then clamp the C / C composite material sample with SiC coating on the cathode clamp in the hydrothermal kettle, the anode is graphite, and then seal the hydrothermal kettle Then p...

Embodiment 2

[0055] (1) First take an appropriate amount of Y 2 SiO 5 Powder, β-Y 2 Si 2 o 7 Whiskers, control the mass ratio of the two: β-Y 2 Si 2 o 7 Whiskers: 20wt%, Y 2 SiO 5 Powder: 80wt%, dispersed in isopropanol, prepared into a suspension with a concentration of 20g / L, then put the suspension into an ultrasonic generator and vibrated for 8 minutes, took it out, put it into a magnetic rotor, and placed it on a magnetic stirrer Stir for 18h to obtain suspension A;

[0056] (2) Add iodine elemental substance to the suspension A to obtain a mixture, the concentration of iodine in the mixture is 2g / L, then place it on a magnetic stirrer to stir and heat, the stirring time is 1h, and the heating temperature is 80°C to obtain a solution B;

[0057] (3) Pour the suspension B into the hydrothermal kettle, then clamp the C / C composite material sample with SiC coating on the cathode clamp in the hydrothermal kettle, the anode is graphite, and then seal the hydrothermal kettle Then ...

Embodiment 3

[0065] (1) First take an appropriate amount of Y 2 SiO 5 Powder, β-Y 2 Si 2 o 7 Whiskers, control the mass ratio of the two: β-Y 2 Si 2 o 7 Whiskers: 10wt%, Y 2 SiO 5 Powder: 90wt%, dispersed in isopropanol, prepared into a suspension with a concentration of 15g / L, then put the suspension into an ultrasonic generator and vibrated for 5 minutes, took it out, put it into a magnetic rotor, and placed it on a magnetic stirrer Stir for 24h to obtain suspension A;

[0066] (2) Add iodine elemental substance to the suspension A to obtain a mixture, the concentration of iodine in the mixture is 1g / L, then place it on a magnetic stirrer to stir and heat, the stirring time is 2h, and the heating temperature is 70°C to obtain a solution B;

[0067] (3) Pour the suspension B into the hydrothermal kettle, then clamp the C / C composite material sample with SiC coating on the cathode clamp in the hydrothermal kettle, the anode is graphite, and then seal the hydrothermal kettle Then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com