Graphene modified polyurethane insulation board and production method thereof

A polyurethane thermal insulation board and graphene modification technology, applied in thermal insulation, chemical instruments and methods, layered products, etc., can solve the problem of no obvious improvement in thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

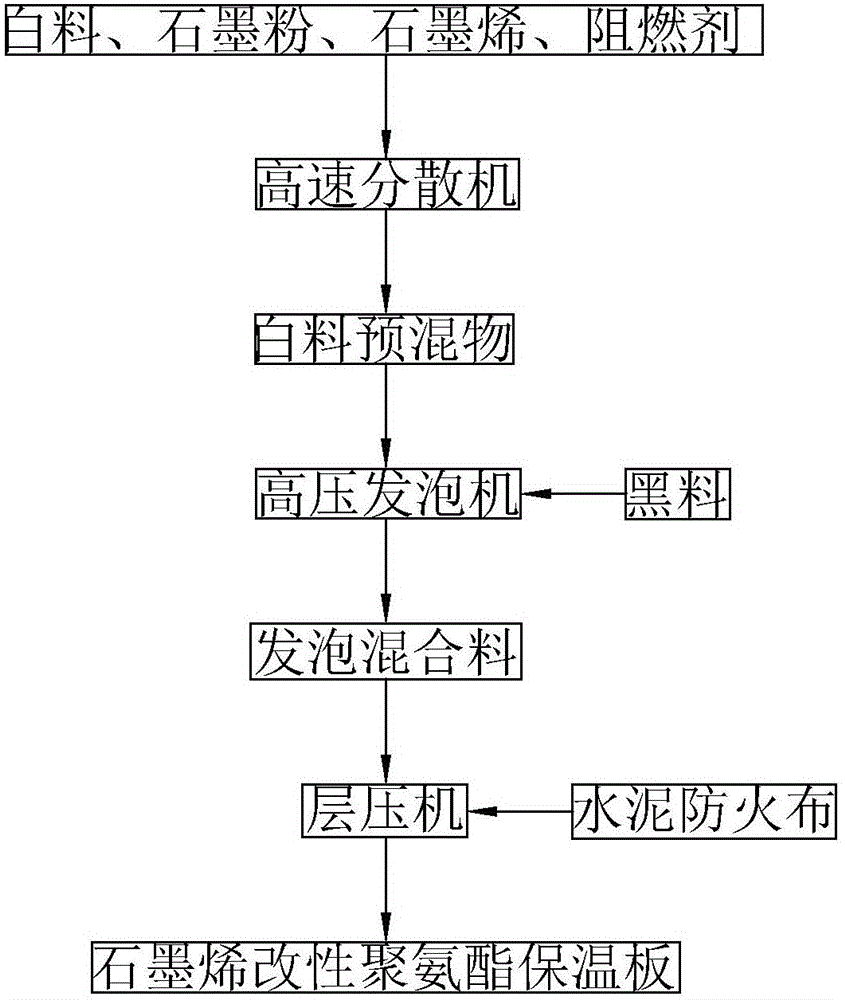

[0038] Example 1: Combining figure 1 and figure 2 The preparation process of graphene modified polyurethane insulation board is described as follows:

[0039] (1) Put 1000g of polyether polyol, 250g of 200-mesh graphite, 5g of graphene, and 5g of dimethyl methylphosphonate into a reaction kettle for pre-mixing for 15 minutes, disperse using a high-speed disperser, and set the speed at 3000r / s to obtain White stock premix.

[0040] (2) Mix the white material premix and 1500 g of polymethyl polyphenylisocyanate and place it in a high-pressure foaming machine, and set the pressure at 0.22 MPa to obtain a mixture.

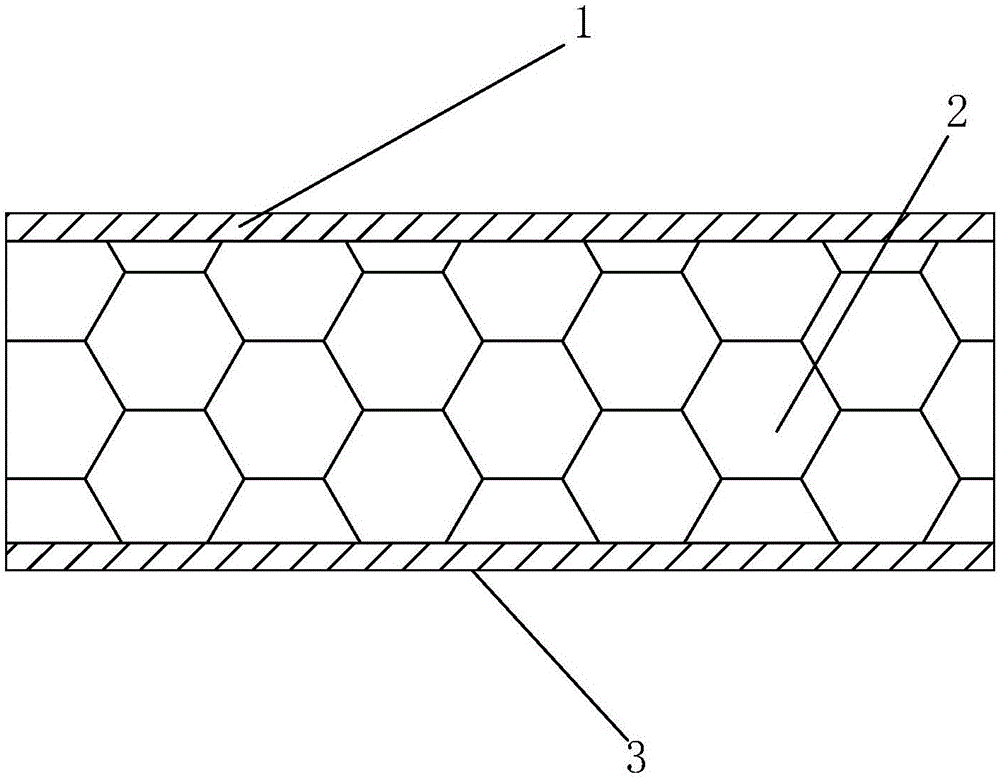

[0041] (3) The laminator includes two upper and lower chain plates. Before the mixture is put into the laminator, the second cement fireproof cloth 3 is pre-laid on the lower chain plate of the laminator, and the upper chain plate of the laminator is transmitted through the rotating shaft. The first cement fireproof cloth1. Spread the mixture evenly on the second ...

Embodiment 1

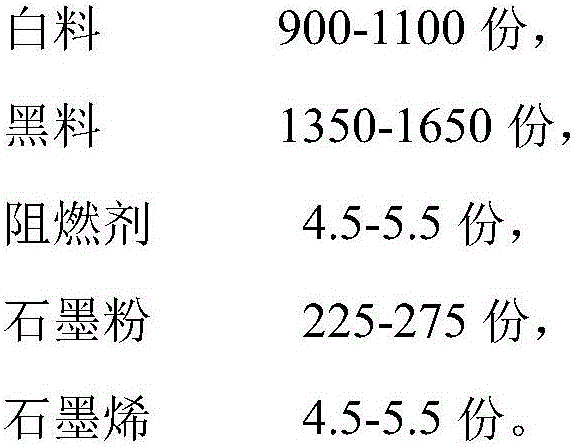

[0057] In Example 1, the graphene-modified polyurethane insulation composite board includes the following components expressed in parts by weight: 1000 parts of polyether polyol, 1500 parts of polymethyl polyphenylisocyanate, 5 parts of dimethyl methylphosphonate , 250 parts of 200 mesh graphite powder, 5 parts of graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com