A kind of production method of impregnated film paper with low formaldehyde emission

A technology of impregnating adhesive film and low formaldehyde release, which can be used in paper, papermaking, paper coating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of urea-formaldehyde resin:

[0031] Formula: 100kg of formaldehyde with a concentration of 37%, 76kg of urea with a concentration of 98%, 15kg of water, and 7kg of compound additives. The molar ratio of formaldehyde to urea, F / U=0.99

[0032] method:

[0033] (1) Put 100kg of formaldehyde into the reactor at one time, put in 32.7kg of urea, add 15kg of water, and adjust the pH to 8.0 with sodium hydroxide solution;

[0034] (2) Open the oil valve and raise the temperature to 80°C, stop the heat supply, let it automatically rise to 85°C, keep warm for 30 minutes, add formic acid solution, control the pH value at 4.5, and carry out polycondensation reaction at 92°C;

[0035] (3) Add 7kg of compound additives and adjust the pH to 7.0 when the glue solution appears dense white mist in 20°C water, and add 24.3kg of urea when the temperature is lowered to 85°C;

[0036] (4) Cool down to 65°C and add 19kg of urea, adjust the pH to 7.0, continue to cool down to ...

Embodiment 2

[0054]The difference between the impregnated film paper described in this embodiment and Example 1 is: the total amount of urea added during the preparation of urea-formaldehyde resin is 78kg, the molar ratio of formaldehyde to urea, F / U=0.96; in the preparation step of urea-formaldehyde resin The add-on of the first batch of urea in (1) is 33.5kg; The add-on of the second batch of urea in the urea-formaldehyde resin preparation step (3) is 25kg; The add-on of the third batch of urea in the urea-formaldehyde resin preparation step (4) is 19.5kg; if there is a parameter range, the middle value of the corresponding parameter range is taken; others are the same as in Example 1.

Embodiment 3

[0056] The difference between the impregnated film paper described in this embodiment and Example 1 is: the total amount of urea added during the preparation of urea-formaldehyde resin is 80kg, the molar ratio of formaldehyde to urea, F / U=0.94; in the preparation step of urea-formaldehyde resin The addition amount of the first batch of urea in (1) is 34.4kg; the addition amount of the second batch of urea in the urea-formaldehyde resin preparation step (3) is 25.6kg; the addition amount of the third batch of urea in the urea-formaldehyde resin preparation step (4) It is 20kg; if there is a parameter range, take the end value of the corresponding parameter range (Example 1 takes the first end value). Others are the same as in Example 1.

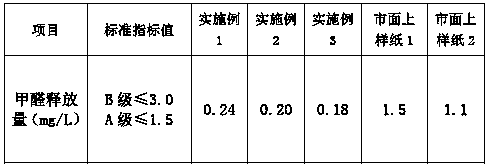

[0057] Table 1

[0058] Example 1-3 is compared with the detection value of formaldehyde emission of impregnated film paper on the market as shown in Table 1

[0059]

[0060] It can be seen from Table 1 that the formaldehyde emission of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com