Ignition supercharging type engine braking method

An engine braking and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., to achieve the effect of increasing resistance and increasing braking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

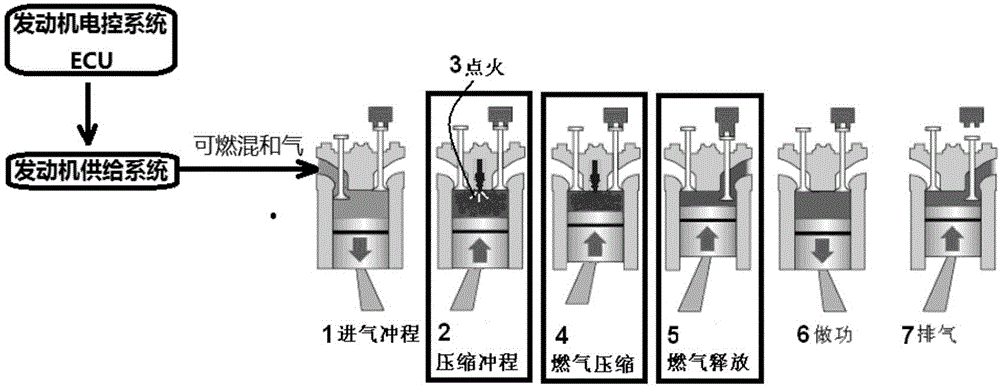

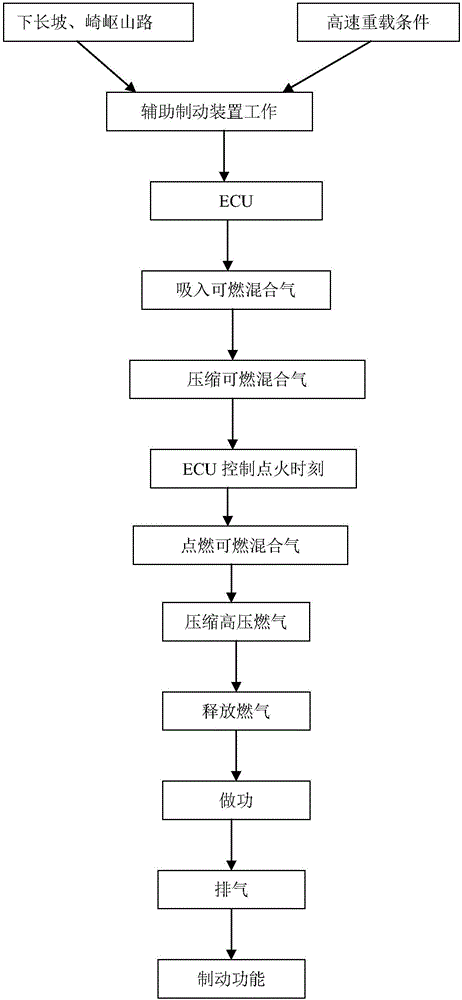

[0025] Such as figure 1 As shown, the principle of the ignition supercharged engine braking technology of the present invention consists of seven working stages: intake stroke 1, compression stroke 2, ignition 3, gas compression 4, gas release 5, work 6, and exhaust 7.

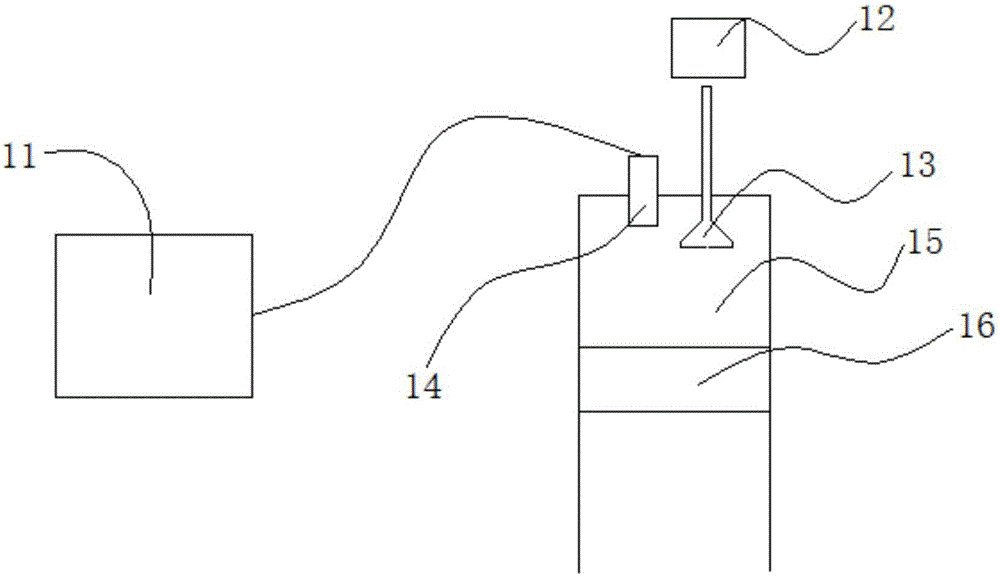

[0026] An ignition supercharged engine braking method, the device providing engine braking includes an electronic control unit 11, an engine braking device 12, an exhaust valve 13, an ignition device 14, a cylinder 15, a piston 16 and an engine supply system; specific steps as follows:

[0027] Step 1: In the intake stroke stage, the electronic control unit 11 sends a signal to the engine supply system to suck the combustible mixture gas into the cylinder 15 as a working medium;

[0028] Step 2: the electronic control unit 11 collects the crankshaft position signal of the crankshaft sensor, sends an instruction to the ignition device 14 after the compression stroke starts, ignites the combustible gas mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com