Reflective fiber sensor for liquid temperature measurement

A fiber optic sensor and liquid temperature technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of dynamic response influence, measurement limitation of fiber optic temperature sensor, etc., achieve fast response, eliminate light source light power changes, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

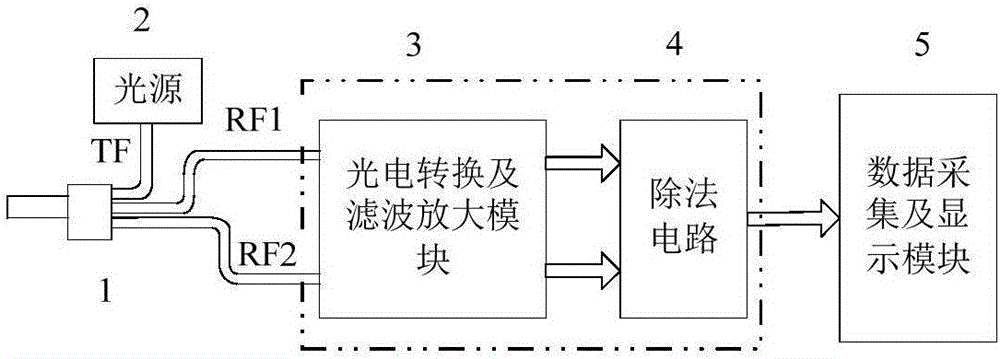

[0025] see figure 1 As shown, the present invention is a reflective optical fiber sensor for liquid temperature measurement, including an optical fiber probe 1, a light source 2, a photoelectric conversion and filter amplification module 3, a division circuit 4 (which can be replaced by a host computer) and an acquisition and display module 5 .

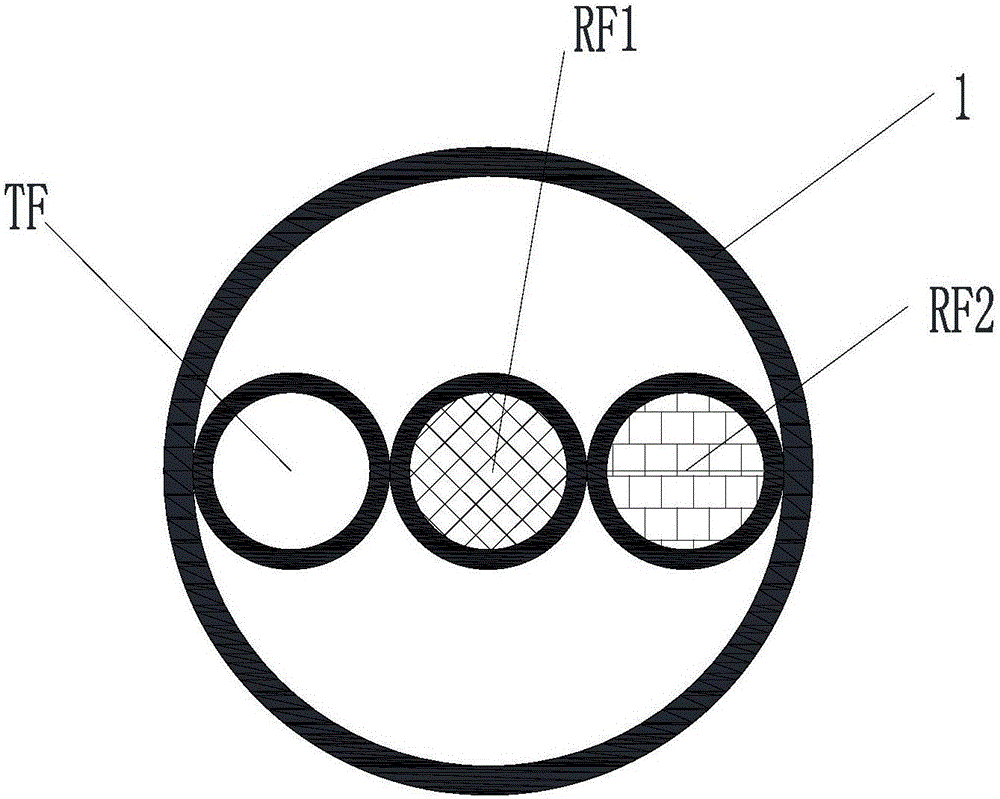

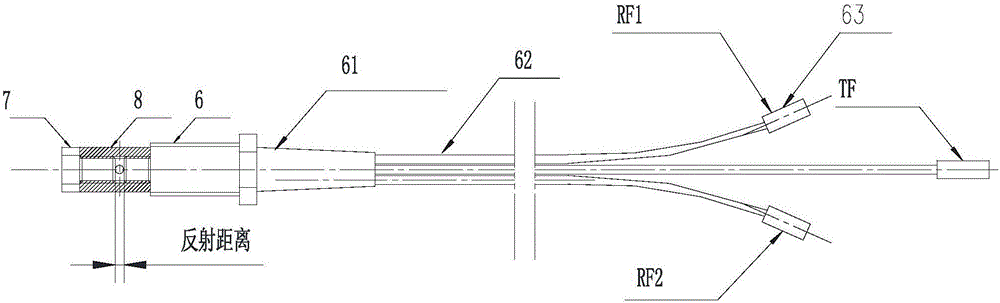

[0026] The light source 2 is a semiconductor laser with a wavelength of 650nm, and the acquisition and display module 5 is composed of a single-chip microcomputer and its peripheral circuits. For the fiber arrangement of fiber optic probe 1, see figure 2 , where one transmitting fiber TF and two receiving fibers are the first receiving fiber RF1 and the second receiving fiber RF2 respectively, and the axial distance between the two receiving fibers and the transmitting fiber is different: the first receiving fiber RF1 is arranged on the transmitting fiber Between TF and the second receiving optical fiber RF2, the axes of the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com