Preparation method and application of carbon nitrogen/titanium dioxide composite material

A technology of titanium dioxide and composite materials, applied in the direction of titanium dioxide, titanium oxide/hydroxide, material analysis using wave/particle radiation, etc., can solve the problems of affecting photoelectric detection, easy recombination of electrons and holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of carbon nitrogen / titanium dioxide composite material, comprising: mixing carbon nitride, trivalent titanium salt, hydrogen peroxide and anionic surfactant in water, heating and reacting to obtain an intermediate product; Calcined in a protective atmosphere to obtain a carbon nitrogen / titanium dioxide composite material.

[0031] The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0032] Wherein, the carbon nitride can be carbon nitride well-known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably prepared according to the following method: melamine is calcined at high temperature in a protective atmosphere to obtain carbon nitride.

[0033] According to the present invention, it is preferred to adopt temperature-programmed melamine to reach the temperature of high-temperature calcinati...

Embodiment 1

[0046] 1.1 Synthesis of ultrathin carbon nitride:

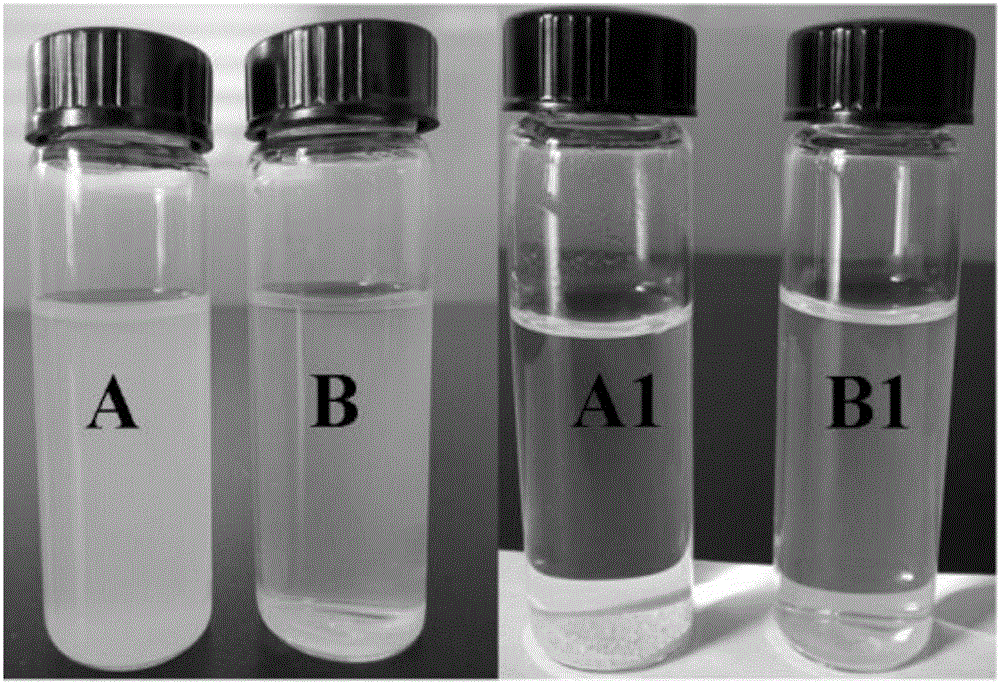

[0047] Weigh 2 grams of melamine and put it into a crucible, and heat it to 500°C under a nitrogen atmosphere (the heating rate of the temperature program is 2.5K min -1 ), held at constant temperature for 2 hours, then cooled to room temperature. Centrifuge and wash several times with methanol and secondary water respectively, and dry at 70°C for 12 hours to obtain bulk carbon nitride (abbreviated as bg-C 3 N 4 ). Ultrasonic disperse the obtained product into secondary water, let the solution settle naturally, then centrifuge to take the supernatant for later use, and obtain ultra-thin carbon nitride (utg-C for short). 3 N 4 );

[0048] 1.2 Synthesis of ultra-thin carbon-nitrogen / titanium dioxide composites:

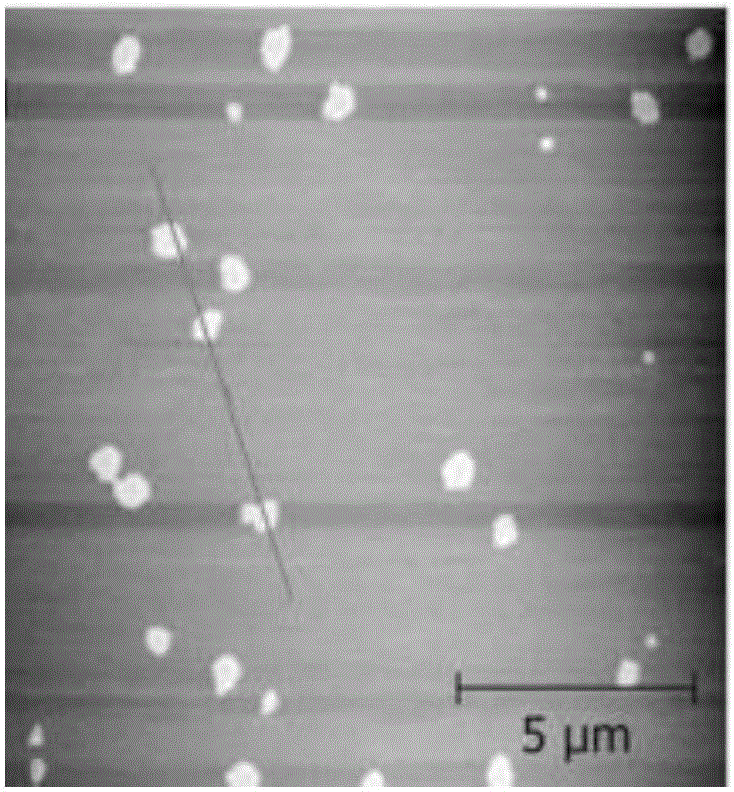

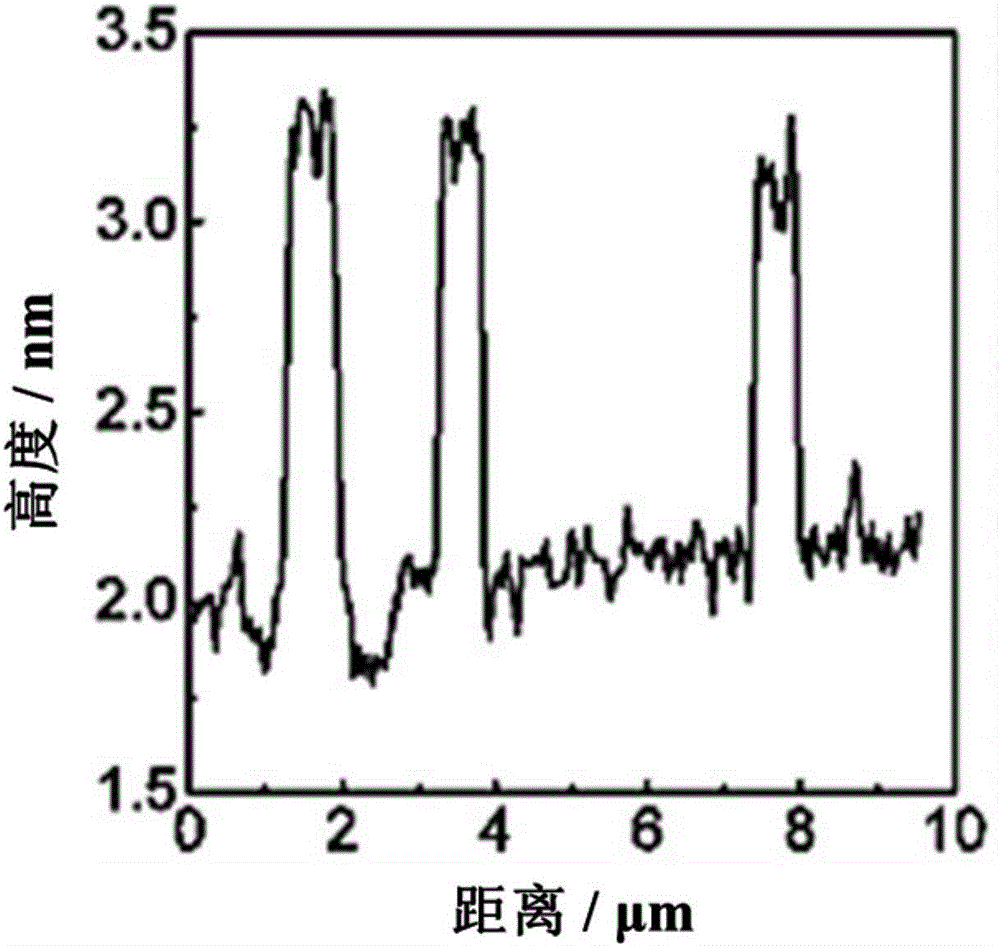

[0049] 3 mg utg-C 3 N 4 and 1.5 mg of sodium dodecylsulfonate were dispersed in secondary water and stirred evenly for 1 hour. Next, 10 milliliters of titanium trichloride (0.6 mol per liter) and 5 milliliters...

Embodiment 2

[0060] 2.1 Synthesis of ultrathin carbon nitride:

[0061] Weigh 2 grams of melamine and put it into a crucible, and heat it to 530°C under a nitrogen atmosphere (the heating rate of the temperature program is 2.5K min -1 ), held at constant temperature for 2 hours, then cooled to room temperature. Centrifuge and wash several times with methanol and secondary water respectively, and dry at 70°C for 12 hours to obtain bulk carbon nitride (abbreviated as bg-C 3 N 4 ). Ultrasonic disperse the obtained product into secondary water, let the solution settle naturally, then centrifuge to take the supernatant for later use, and obtain ultra-thin carbon nitride (utg-C for short). 3 N 4 ).

[0062] 2.2 Synthesis of ultrathin carbon nitride / titanium dioxide composites:

[0063] 3 mg utg-C 3 N 4 and 2 mg of sodium dodecylsulfonate were dispersed in secondary water and stirred evenly for 1 hour. Next, 15 milliliters of titanium trichloride (0.6 mol per liter) and 5 milliliters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com