Synthesis method of sub-five nanometer truncated octahedron PtCu nanocrystal

A technology of nanocrystals and synthesis methods, applied in the field of synthesis of PtCu nanocrystals, can solve the problems of new alloy crystal structure, low quality activity and high cost, and achieve the effects of novel crystal structure, excellent catalytic performance and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

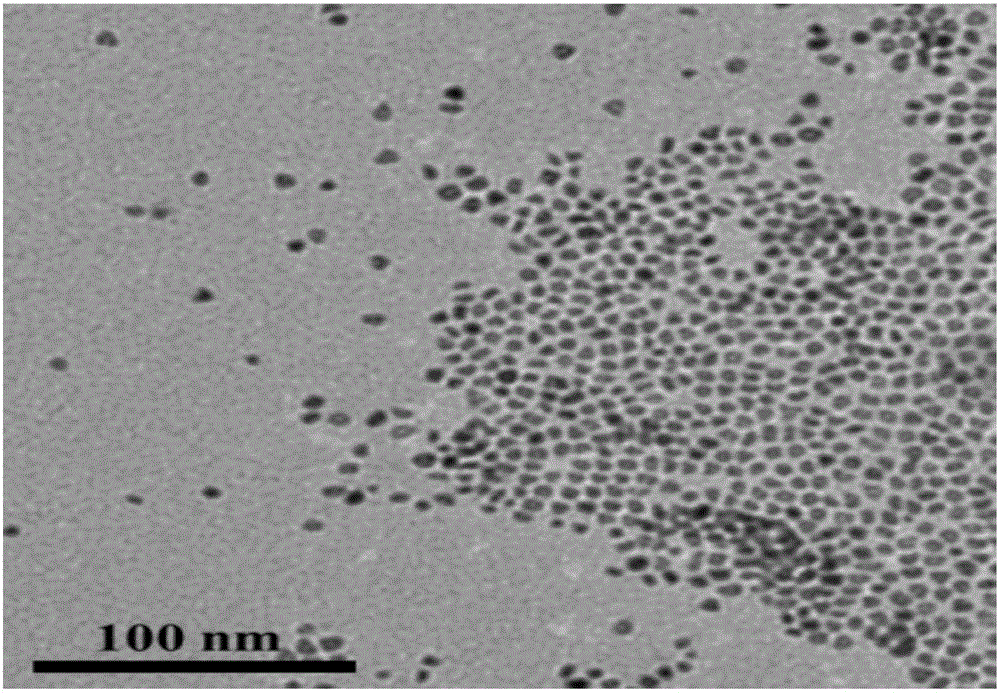

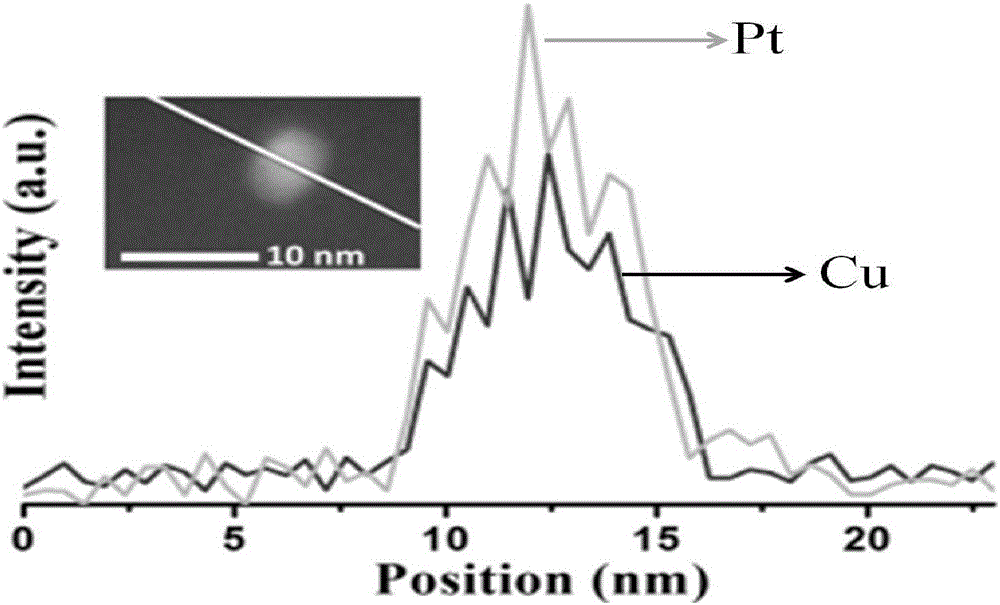

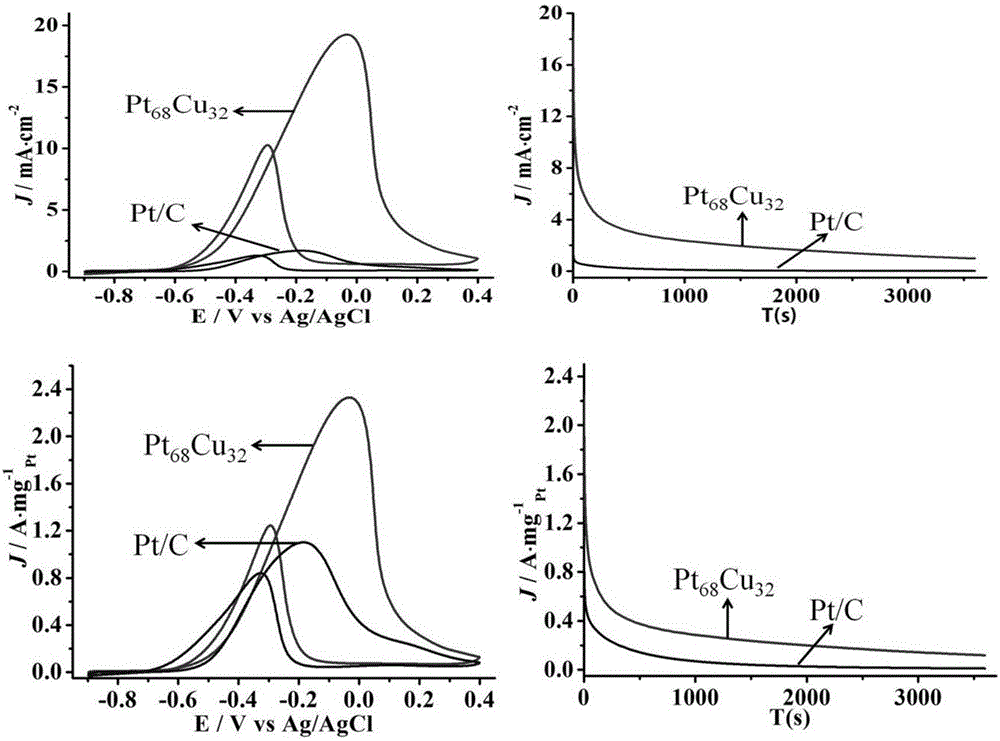

[0027] Such as Figure 1~4 Shown, a kind of synthetic method of the PtCu nanocrystal of sub-5 nanometer truncated octahedron comprises the steps:

[0028] In the first step, add PVP and NaI into the organic solvent DMF together, and stir at room temperature for 5-8 minutes;

[0029] The second step, adding 0.01 to 0.1 mol of metal platinum salt precursor solution and copper salt precursor solution to the mixed solution obtained in step (1), stirring at room temperature for 3 to 10 minutes;

[0030] The third step, adding hydroxylamine hydrochloride to the mixed solution obtained in step (2), stirring at room temperature for 1 to 10 minutes;

[0031] The fourth step is to transfer the mixed solution obtained in step (3) to an autoclave for a reaction time of 2 to 12 hours, and the temperature of the autoclave is controlled at 100 to 150°C;

[0032] The fifth step is cooling the product obtained in step (4), washing it, and centrifuging to obtain sub-5 nm truncated octahedral ...

Embodiment 1

[0038] A kind of synthetic method of the PtCu nano crystal of sub-5 nanometer truncated octahedron, comprises the steps:

[0039] (1) Add PVP and NaI to the organic solvent DMF together, stir at room temperature for 5-8 minutes, the mass ratio of PVP to NaI is 1:3; the amount of organic solvent DMF added needs to completely dissolve PVP and NaI;

[0040] (2) Add metal platinum salt and copper salt precursor solution to the mixed solution obtained in step (1), the amount of metal salt precursor is 0.01-0.1mol; stir at room temperature for 3-10 minutes, the platinum salt precursor and copper salt The molar ratio of the precursor is 1:1;

[0041] (3) Add hydroxylamine hydrochloride to the mixed solution obtained in step (2), stir at room temperature for 1 to 10 minutes, and the mass ratio of hydroxylamine hydrochloride to PVP is 3:1;

[0042] (4) Transfer the mixed solution obtained in step (3) to an autoclave for reaction for 8 hours, and control the temperature at 130°C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com