A Plasma Synthetic Jet Actuator for High Altitude Vehicles

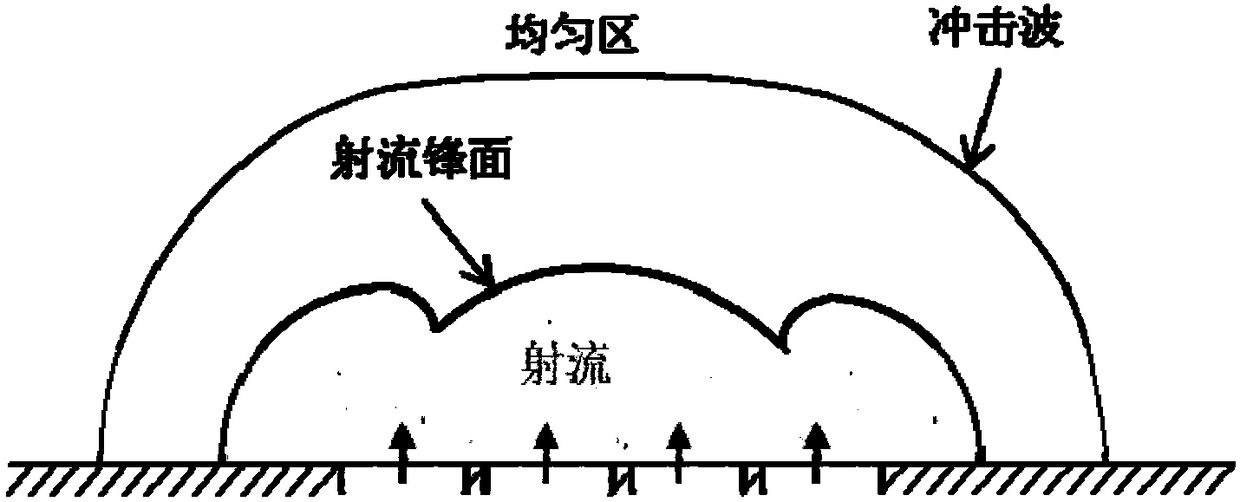

A plasma and synthetic jet technology, applied in the direction of plasma, electrical components, etc., can solve the problems of gas path organization and flow control effect, failure to achieve plasma synthetic jet, effective work of jet actuator, etc., to improve uniformity and momentum exchange ability, improve flow uniformity and momentum exchange ability, and broaden the effect of flow control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

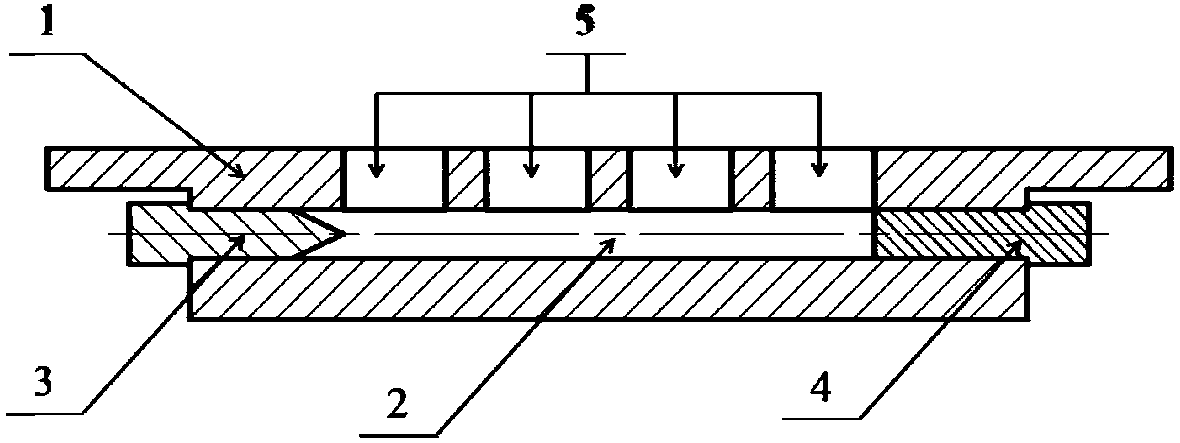

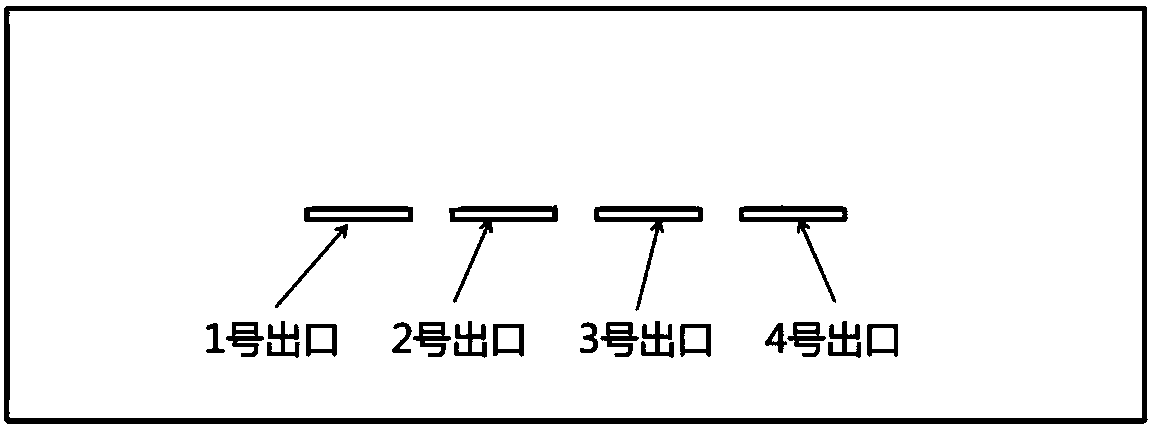

[0017] see figure 1 and figure 2 Shown, be that the present invention is used for a kind of high-altitude aircraft plasma synthetic jet exciter, comprise exciter body 1, cathode discharge electrode 3, anode discharge electrode 4, cathode discharge electrode 3, anode discharge electrode 4 external high-voltage pulse power supply (not shown icon). The exciter body 1 is provided with through holes 2 passing through both ends of the exciter body. The cathode discharge electrode 3 and the anode discharge electrode 4 are made of tungsten copper alloy. The upper surface of the exciter body 1 is also provided with several air release grooves 5 communicating with the through holes. The cathode discharge electrode 3 is inserted and fixed at one end of the through hole 2 , while the anode discharge electrode 4 is inserted and fixed at the other end of the through hole 2 . The cathode discharge electrode 3, the anode discharge electrode 4 and the through hole 2 are sealed with high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com