Preparation method for mesoporous-microporous composite hydroisomerization dewaxing catalyst

A catalyst and microporous technology, which is applied in the field of preparation of mesoporous-microporous composite molecular sieve and its hydroisomerization catalyst, can solve the problems of few application reports and the like, and achieve the effect of high dispersion of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The synthesis of ZSM-23 is according to the disclosed method of U.S. Patent US4076842: 1. 13.76g aluminum sulfate, 64g deionized water and 6.8gNaOH are mixed, stirred evenly, then add 36.4g pyrrolidine and continue to stir; 2. 321.9g silica sol (30% SiO 2 ,70%H 2 0) Add the above solution and stir until a gel is formed; ③ put the above gel in a high-pressure reactor to heat and stir, and continuously crystallize at 180°C for 72h; ④ Wash and filter the product until the filtrate is neutral, and The filter cake was dried at 110°C for 8h to obtain SiO 2 / Al 2 o 3 ZSM-23 molecular sieve raw powder with a molar ratio of about 40. The amount of aluminum sulfate is Al 2 o 3 In terms of, the amount of NaOH is Na 2 In terms of O, the amount of silica sol is SiO 2 Calculated, the feeding molar ratio is as follows: SiO 2 / Al 2 o 3 =40,Na 2 O / SiO 2 =0.05, Pyd / SiO 2 =0.32,H 2 O / SiO 2 =10.

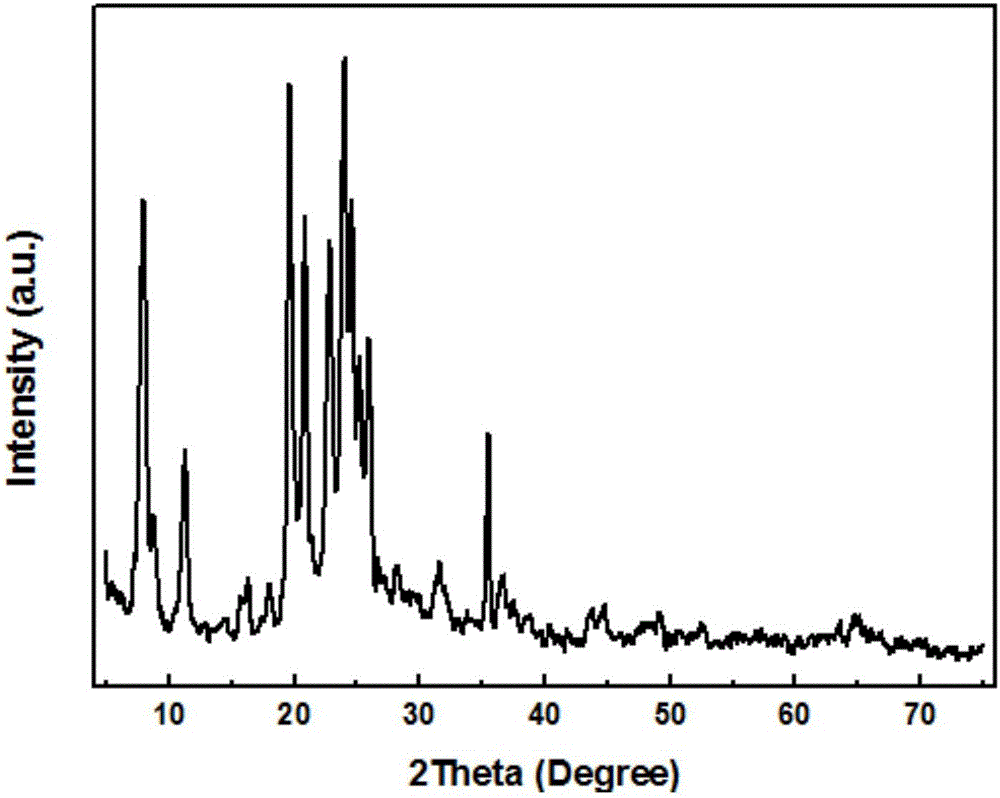

[0058] Some samples were taken for X-ray diffraction analysis. figure 1 The...

Embodiment 2

[0060] Weigh 16g cetyltrimethylammonium bromide (CTAB), add 777g deionized water, stir until dissolved, then add 33.3g silica sol (30% SiO 2 , 70%H 2 O), 1.25g aluminum sulfate, 40g ZSM-23 molecular sieve powder, mix evenly, finally add a certain amount of NaOH to adjust the pH of the solution to 10-11, and continue to stir for 2h. The reaction solution was put into a crystallization kettle, and crystallized at 120°C for 24 hours; the reaction product was cooled, washed, and dried to obtain the composite molecular sieve powder As-ZM. The mesoporous MCM-41 molecular sieve accounts for about 20 wt% of the composite molecular sieve.

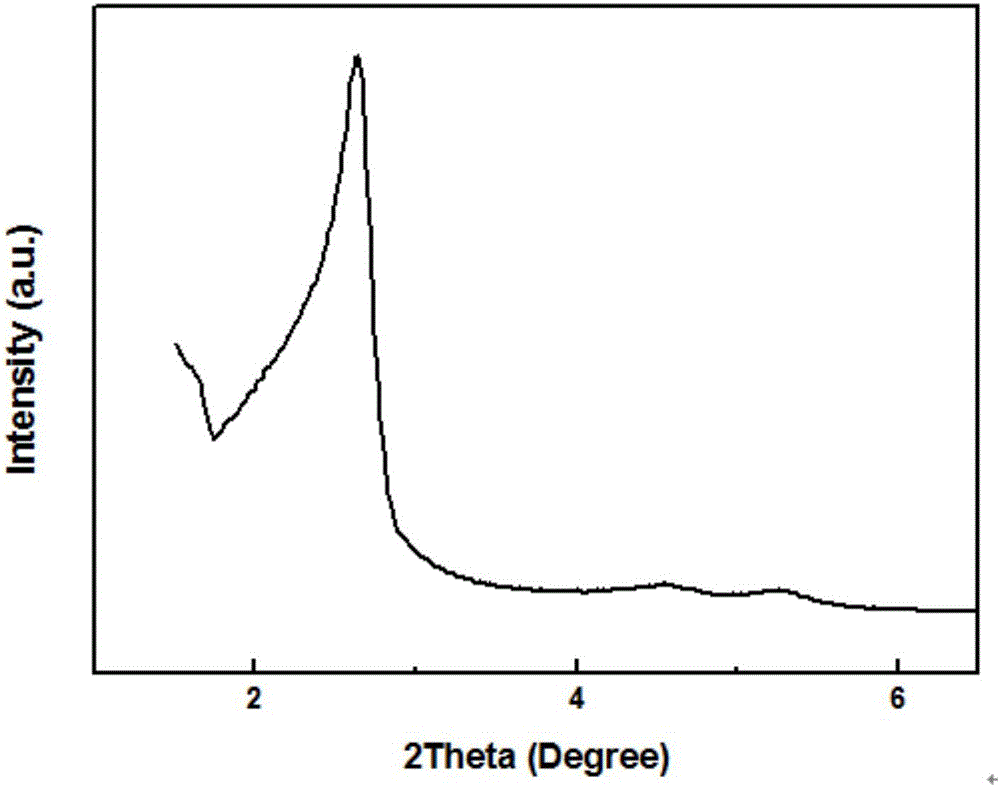

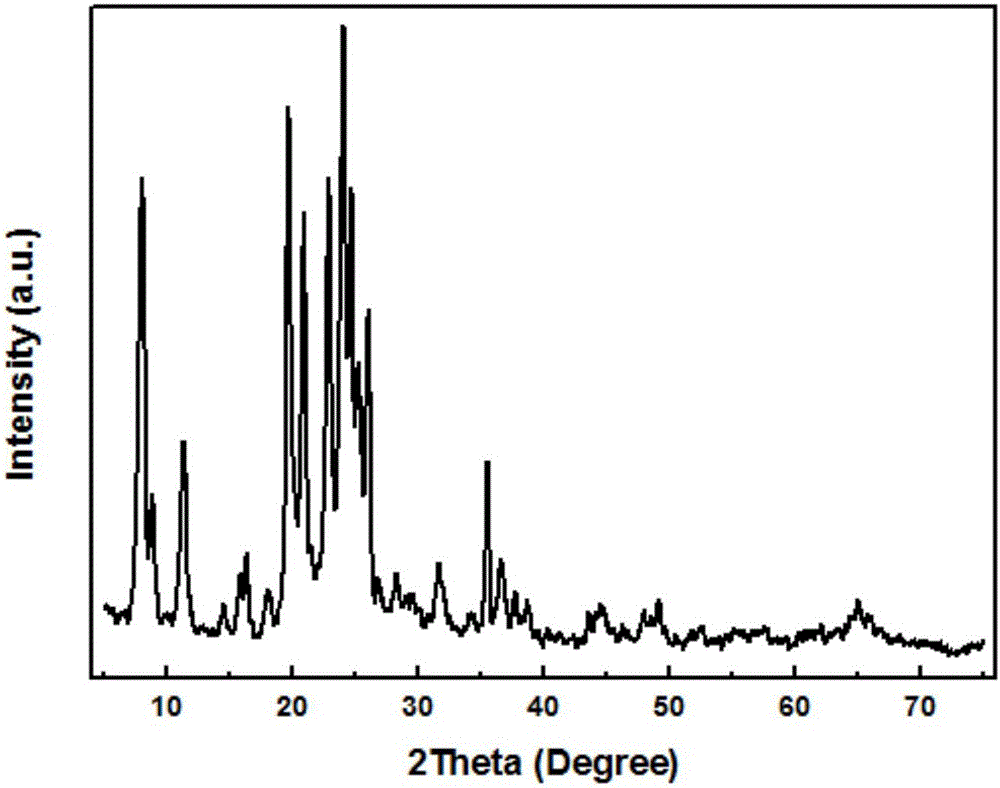

[0061] Some samples were taken for X-ray diffraction analysis. figure 2 It is the wide-angle XRD pattern of composite molecular sieve ZM, and the result shows that there is ZSM-23 molecular sieve in the obtained sample, image 3 The small-angle XRD diffraction pattern of the composite molecular sieve ZM shows that MCM-41 molecular sieve exists i...

Embodiment 3

[0063] Weigh 24g P123, add 577g deionized water, stir until dissolved, then add 33.3g silica sol (30% SiO 2 ,70%H 2 O), 1.25g aluminum sulfate, 40g ZSM-23 molecular sieve powder, mix evenly, finally add a certain amount of HCl to adjust the pH of the solution to 2-4, and continue to stir for 2h. The mixed slurry was put into a crystallization kettle, and crystallized at 100°C for 24 hours; the reaction product was cooled, washed, and dried to obtain the composite molecular sieve powder As-ZS. Among them, the mesoporous SBA-15 molecular sieve accounts for about 20 wt% in the composite molecular sieve.

[0064] Some samples were taken for X-ray diffraction analysis. Figure 4 It is the wide-angle XRD pattern of composite molecular sieve ZS, and the result shows that there is ZSM-23 molecular sieve in the obtained sample, Figure 5 The small-angle XRD diffraction pattern of the composite molecular sieve ZS shows that SBA-15 molecular sieve exists in the obtained sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com