A processing method for brazing microstrip boards using printed solder paste

A processing method and technology of microstrip board, applied in metal processing equipment, welding equipment, manufacturing tools, etc., to achieve the effects of improving efficiency, simple operation, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

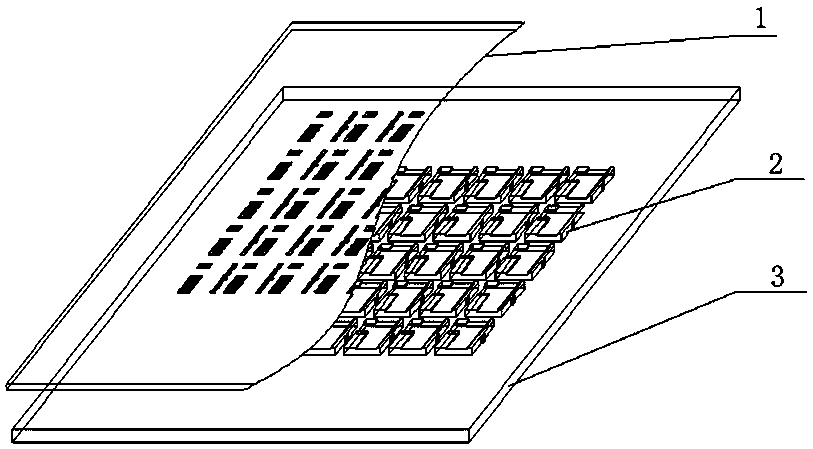

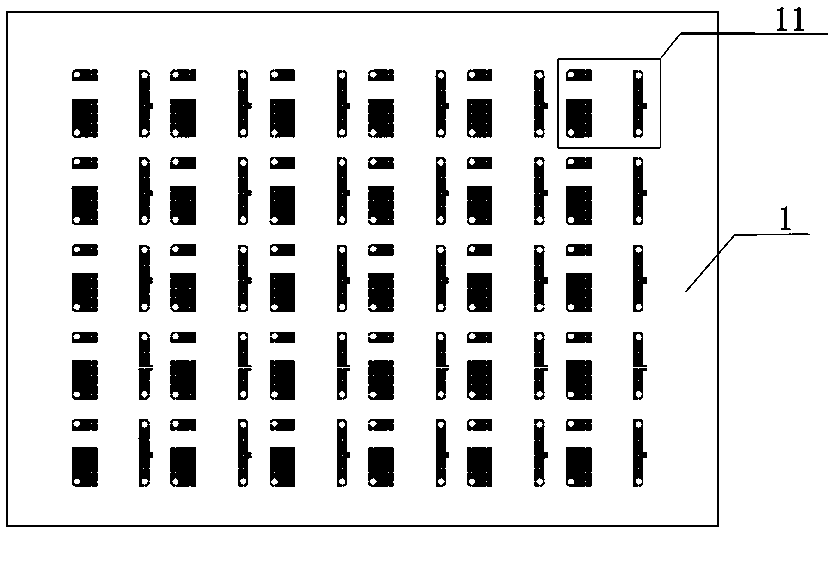

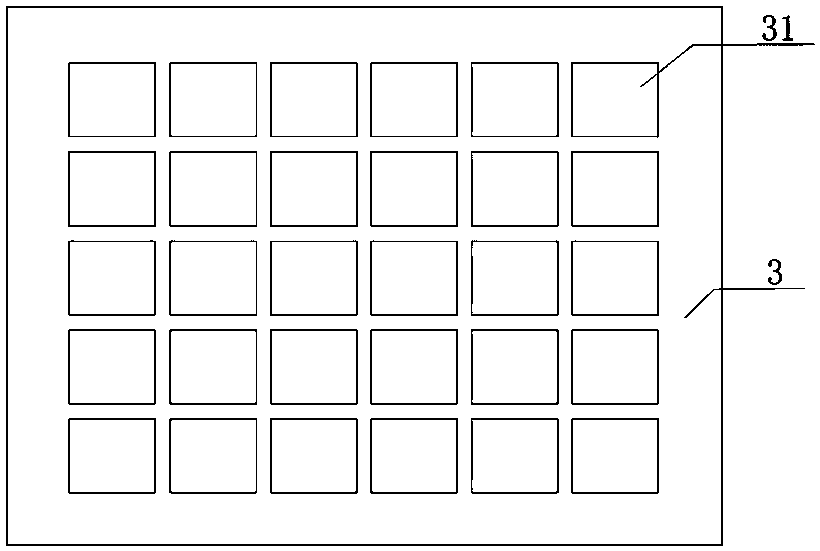

Method used

Image

Examples

Embodiment 1

[0042] Materials used: 1. Solder paste (alpha LR721H3), 2. Absolute ethanol (CH3CH2OH), 3. Dust-free cloth, 4. Anti-static gloves.

[0043] Equipment and tools: 1. Stainless steel scraper (length 200mm), 2. Stencil (370*470mm), 3. Printing platform, 4. Positioning bottom plate, 5. Stirring rod, 6. Solder paste mixer, 7. Ultrasonic cleaner, 8. Reflow oven (VXS374), 9. Thermometer (DATAPAQ / 9000), 10. X-ray detector (Y.Cougar SMT).

[0044] Preparation:

[0045] Take out the stored solder paste from the refrigerator, check the type and expiration date of the solder paste, and stir it with a solder paste mixer: warm it up at room temperature for more than 2 hours before stirring, and stir for 15 minutes.

[0046] Before printing solder paste, use a non-woven cloth to dip an appropriate amount of absolute ethanol to clean the stencil 1. Squeegee, and place them in categories.

[0047] The specific processing steps of the brazed microstrip plate are as follows:

[0048] (1) Clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com