Method and system for removing iron and manganese from underground water

A groundwater, iron and manganese technology, applied in the direction of contaminated groundwater/leachate treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as penetration, effluent manganese not up to standard, iron and manganese oxidation into particles, etc. , to achieve the effect of small structure and site requirements, stable operation, and prevention of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

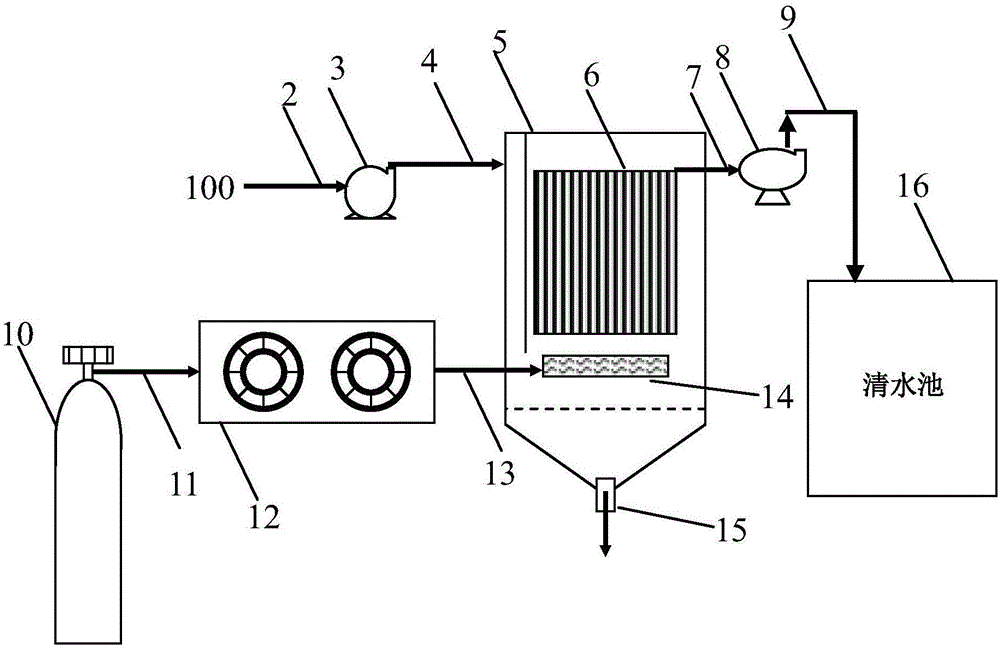

[0030] like figure 1 As shown, the system for removing iron and manganese in groundwater in this specific embodiment includes: an ozone generator 12, a membrane reaction tank 5, a micro-nano aerator 14 and a ceramic membrane module 6 arranged in the membrane reaction tank 5.

[0031] The ozone generator 12 includes an air inlet pipe 11 and an air outlet pipe 13 . The gas source 10 adopts air or pure oxygen that has been pretreated (dust removal, drying, etc.), or oxygen with a purity of 90% to 92% obtained by air compression, freeze drying, and sieving, and the gas source pressure is 0.04 to 0.45MPa . Air source 11 selects air source or oxygen source according to specific needs. The gas source 10 enters the ozone generator 12 through the intake pipe 11, and produces ozone-containing gas through high-voltage discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com