Waste emulsion treatment method and device

A waste emulsion and treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high temperature, waste of energy, and long treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

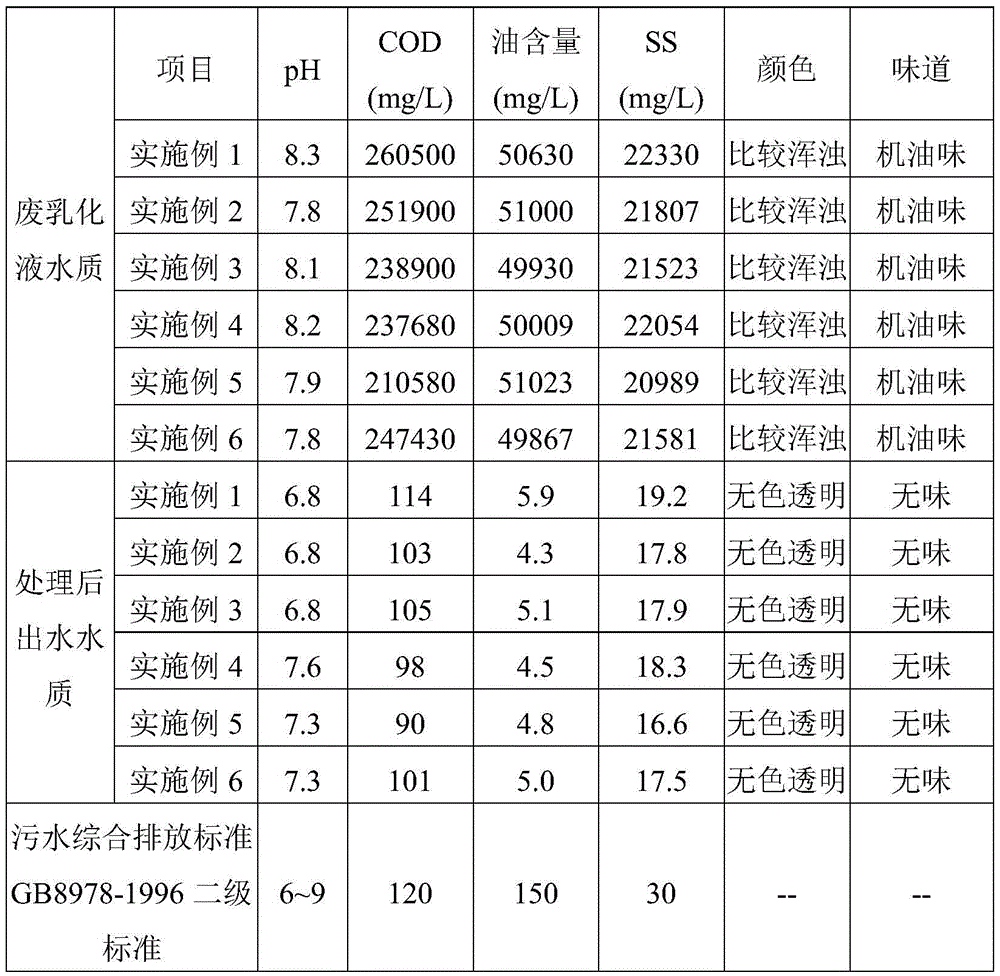

[0052] The water quality composition of a waste emulsion is shown in Table 1.

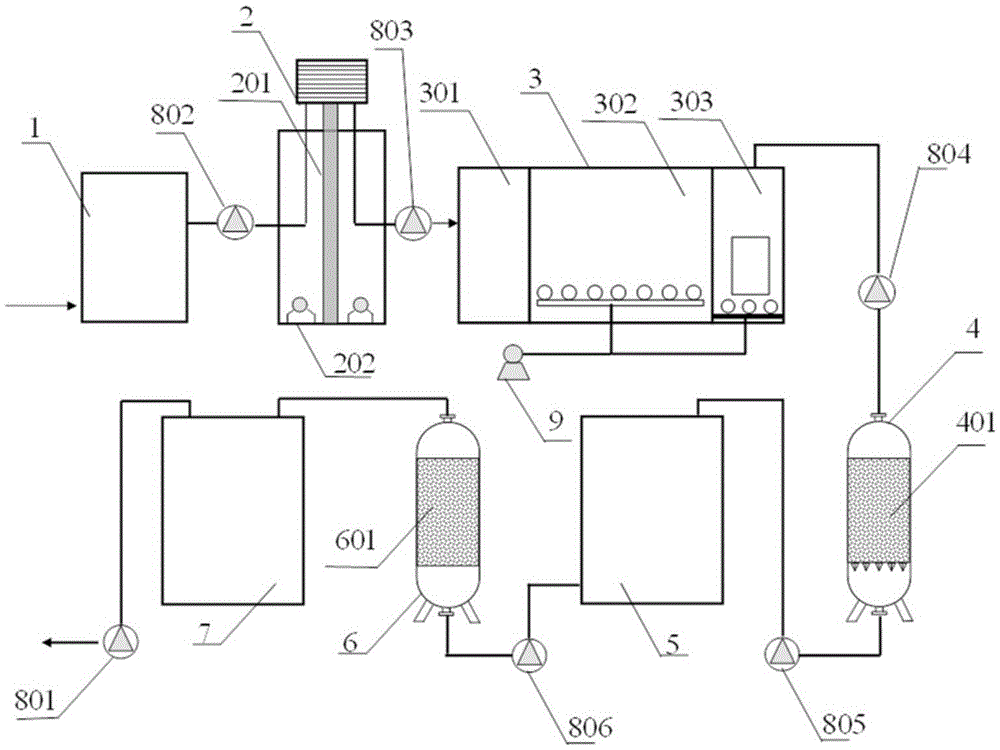

[0053] figure 1 It is a schematic diagram of the processing device of the waste emulsion of Example 1. Among them, the arrow direction is the trend of the waste emulsion in the process flow.

[0054] The above device includes a first water tank 1, a second water pump 802, a solid-liquid separation high-frequency vibrating membrane processor 2, a third water pump 803, a biochemical processor 3, a fourth water pump 804, an ozone oxidation processor 4, a fifth Water pump 805 , second water tank 5 , sixth water pump 806 , activated carbon filter 6 , third water tank 7 , first water pump 801 .

[0055] The solid-liquid separation high-frequency vibrating membrane processor 2 is provided with a vibration center rod 201, and a vibration exciter 202 is provided at the bottom.

[0056] The biochemical processor 3 is sequentially provided with an anaerobic processor 301, an aerobic contact oxidation proce...

Embodiment 2

[0067] The water quality components of a certain waste emulsion are shown in Table 1. Using the treatment device in Example 1, the process for treating the waste emulsion includes the following steps:

[0068] (1) The 45°C waste emulsion is treated by a high-frequency vibrating membrane processor for solid-liquid separation after passing through the feed pump; wherein, the feed water pressure is 2.0MPa, the feed pump frequency is 27.3Hz, the vibration exciter frequency is 46.3Hz, and the concentrated water pressure is 2.0MPa;

[0069] (2) The water produced by the high-frequency vibrating membrane processor for solid-liquid separation is directly subjected to anaerobic treatment, aerobic contact oxidation treatment, and MBR membrane filtration treatment in sequence; among them, the residence time of anaerobic treatment is 48h, the residence time of aerobic treatment is 72h, and the MBR treatment The residence time of membrane treatment is 20h; the aerobic contact oxidation tre...

Embodiment 3

[0074] The water quality components of a certain waste emulsion are shown in Table 1. Using the treatment device in Example 1, the process for treating the waste emulsion includes the following steps:

[0075] (1) The 45°C waste emulsion is treated by a high-frequency vibrating membrane processor for solid-liquid separation after passing through the feed pump; wherein, the feed water pressure is 2.0MPa, the feed pump frequency is 27.3Hz; the vibration exciter frequency is 46.3Hz, and the concentrated water pressure is 2.0MPa;

[0076] (2) The water produced by the high-frequency vibrating membrane processor for solid-liquid separation is directly subjected to anaerobic treatment, aerobic contact oxidation treatment, and MBR membrane filtration treatment in sequence; among them, the residence time of anaerobic treatment is 48h, the residence time of aerobic treatment is 72h, and the MBR treatment The residence time of membrane treatment is 20h; the aerobic contact oxidation tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com