Crystal orientation template for BaTiO3-based lead-free piezoelectric ceramics and method for fabricating the same

A lead-free piezoelectric and crystal orientation technology, which is applied in the field of templates for crystal orientation and its preparation, can solve problems such as improving the piezoelectric characteristics of piezoelectric ceramics, and achieve the effects of reducing tissue defects and high displacement characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of lead-free piezoelectric ceramics for crystal orientation according to the present invention comprises the following steps: (a) carrying out the first mixture comprising titanium oxide and the oxide of element A (however, A is Zr or Sn) for the first time Heat treatment to prepare titanium / element A solid solution oxide powder; (b) perform a second heat treatment on the second mixture comprising the above titanium / element A solid solution oxide powder, bismuth oxide and mixed salt to prepare a plate-shaped template precursor and (c) performing a third heat treatment on the third mixture comprising the above-mentioned plate-shaped template precursor and barium precursor to prepare a plate-shaped template represented by the following chemical formula 1:

[0058] [chemical formula 1]

[0059] Ba(Ti 1-x A x )O 3

[0060] (However, A is Zr or Sn, 0

[0061] Next, by using Ba(Ti 0.9 Zr 0.1 )O 3 The preparation method of the template for ...

Embodiment 1

[0104] (1) contains (Ti 0.9 Zr 0.1 )O 2 Preparation of solid solution powder

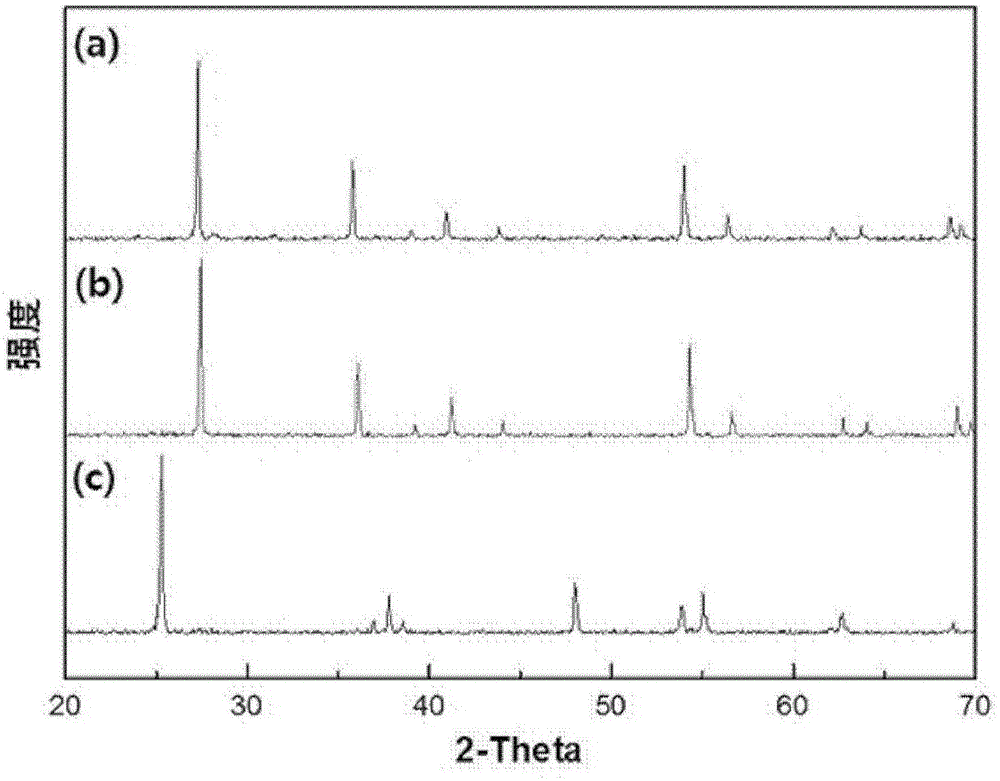

[0105] Weigh titanium dioxide (TiO 2 ), zirconia (ZrO 2 ) raw material powder and use zirconia balls and ethanol as a solvent to crush, dry and put it into an alumina crucible, then heat-treat at 1200°C for 4 hours to make a solid solution powder, and perform X-ray diffraction analysis on the prepared solid solution powder and display the results in the figure 1 .

[0106] Such as figure 1 As shown, for the titanium dioxide powder ( figure 1 (b)) and titanium dioxide raw material powder ( figure 1 (c)) X-ray diffraction analysis results are compared to confirm that the prepared solid solution powder ( figure 1 (a)) is a solid solution of zirconium (Ti 0.9 Zr 0.1 )O 2 Composition ratio of solid solution powder.

[0107] (2) Contains Bi 4 (Ti 0.9 Zr 0.1 )O 12 Preparation of template precursors

[0108] To prepare the template precursor, 3 moles of (Ti 0.9 Zr 0.1 )O 2 Solid solutio...

Embodiment 2

[0119] Except for the second heat treatment at 900 °C for 1 h in the template precursor preparation step and the use of 7 moles of barium carbonate (BaCO 3 , 99%), other parts have utilized the same method as in Example 1 to make templates.

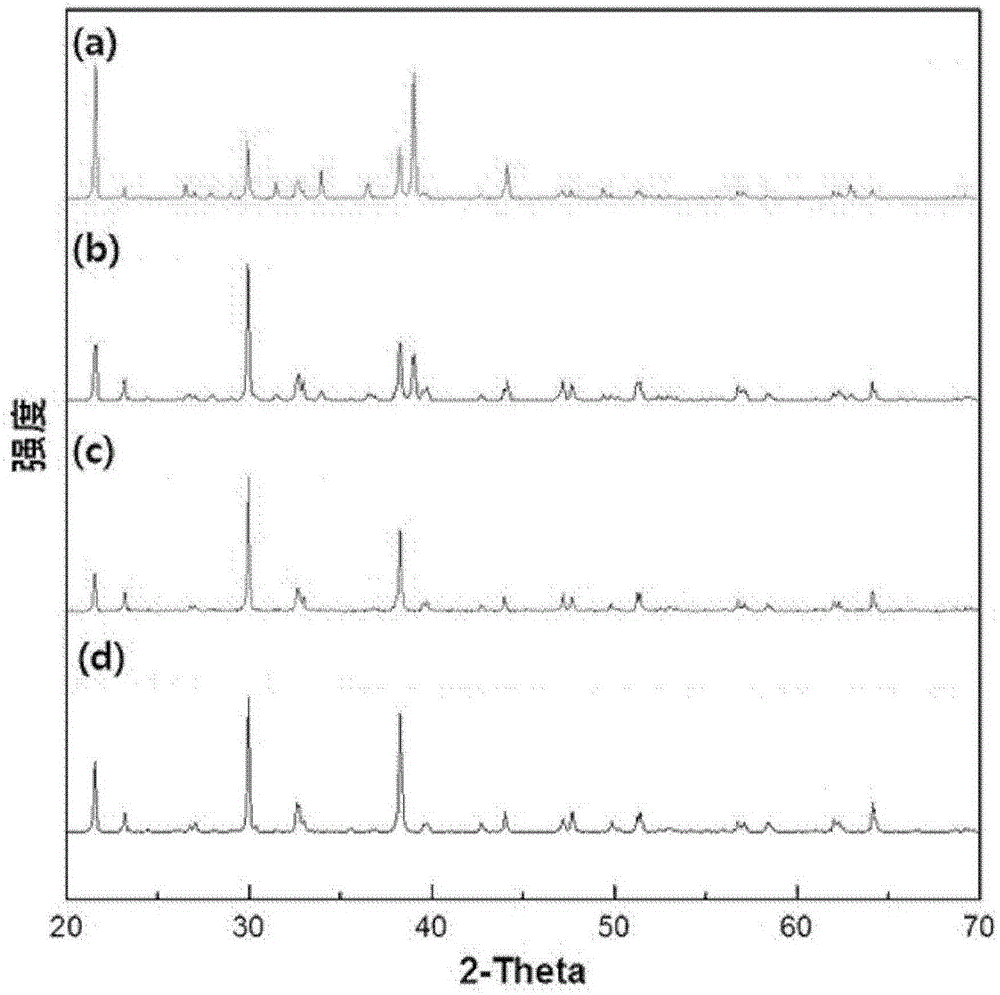

[0120] Furthermore, X-ray diffraction analysis and scanning electron microscope analysis were carried out on the prepared template, and the results are shown in Figure 4 .

[0121] Such as Figure 4 As shown in (a), no additional second phase (second dphase) was detected, such as Figure 4 As shown in (b), it was confirmed that a uniform plate-shaped template of a certain size was formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com