Macromolecular biological energy gathering synergistic fertilizer and preparing technology thereof

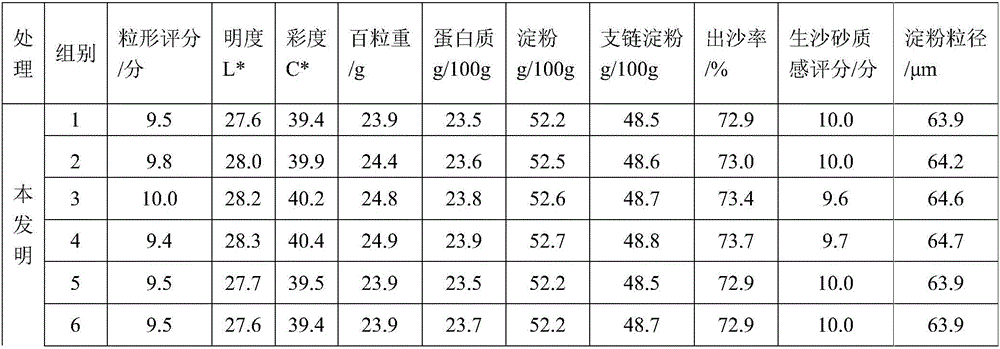

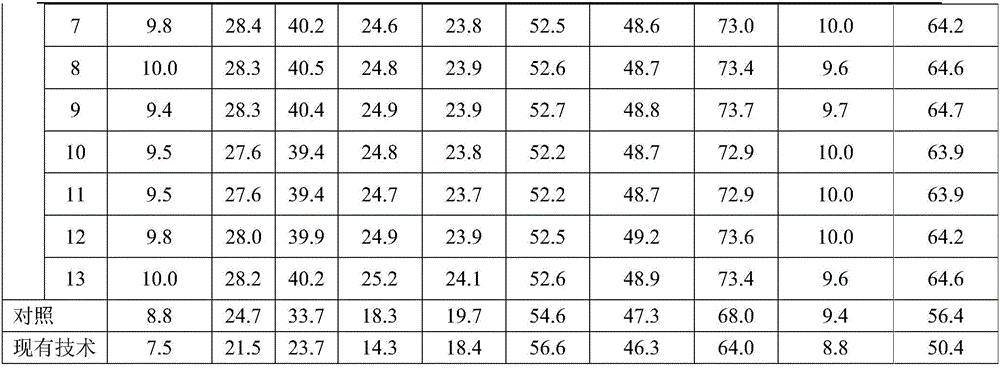

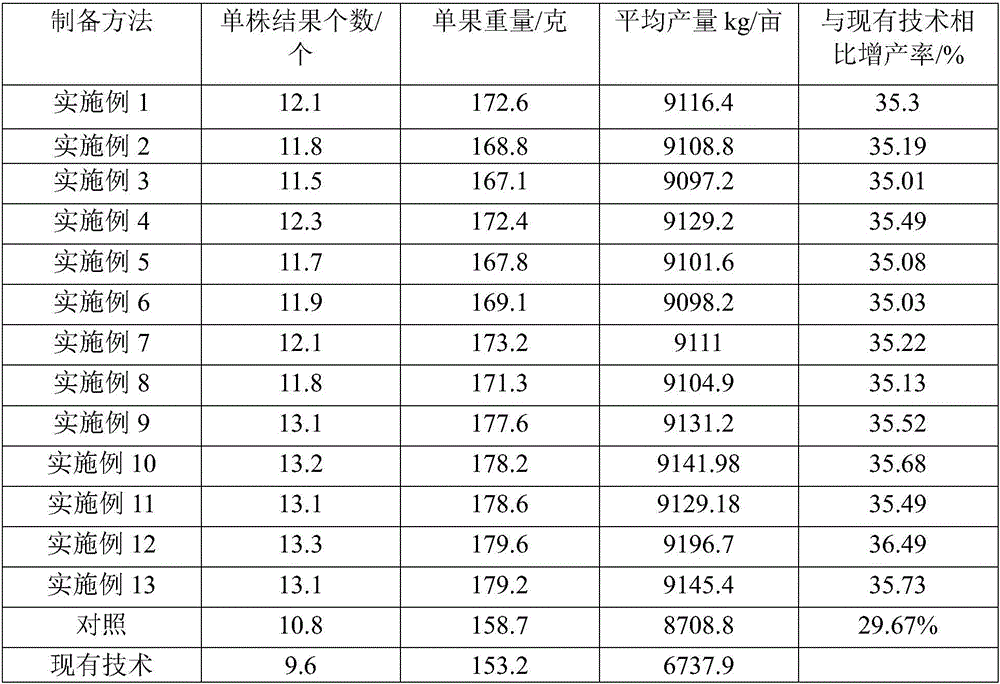

A preparation process and polymer technology, applied in the direction of layered/coated fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of low utilization rate of compound fertilizers, and achieve the promotion of the formation of amino acids, the synthesis of amino acid substances, and the quality of crops Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A macromolecule bio-energy-gathering and synergistic fertilizer comprises the following raw materials in parts by weight: 88 parts of nitrogen-phosphorus binary compound fertilizer and 12 parts of macromolecule bio-energy-gathering synergist.

[0031] The polymer bio-gathering synergist is prepared by the following method:

[0032] A. Preparation of fermented product: Mix plant straw powder and starch with a mass ratio of 3.8:1, then add fermentation agent and water, wherein the amount of fermentation agent is 0.08% of the total mass of plant straw powder and starch, at 58 ℃ constant temperature fermentation for 45 hours, and then 78 ℃ constant temperature fermentation for 40 hours, after the fermented material is dehydrated by the centrifuge, it enters the dryer for drying, and the inlet temperature of the dryer is controlled at 75-80 ℃, and the outlet temperature is 38-42 ℃ , and then transport the dried material to a cooler for cooling to obtain a fermentation produc...

Embodiment 2

[0038] A macromolecule bio-energy-gathering synergistic fertilizer, comprising the following raw materials in parts by weight: 89 parts of nitrogen-phosphorus binary compound fertilizer, and 11 parts of macromolecule bio-energy-gathering synergist.

[0039] The polymer bio-gathering synergist is prepared by the following method:

[0040] A. Preparation of fermented product: Mix plant straw powder and starch with a mass ratio of 3.9:1, then add fermentation agent and water, wherein the amount of fermentation agent is 0.09% of the total mass of plant straw powder and starch, at 59 ℃ constant temperature fermentation for 42 hours, and then 79 ℃ constant temperature fermentation for 34 hours, after the fermented material is dehydrated by the centrifuge, it enters the dryer for drying, and the inlet temperature of the dryer is controlled at 76-79 ℃, and the outlet temperature is 39-41 ℃ , and then transport the dried material to a cooler for cooling to obtain a fermentation product...

Embodiment 3

[0046] A macromolecule bio-energy-gathering synergistic fertilizer, comprising the following raw materials in parts by weight: 90 parts of nitrogen-phosphorus binary compound fertilizer, and 10 parts of macromolecule bio-energy-gathering synergist.

[0047] The polymer bio-gathering synergist is prepared by the following method:

[0048] A. Preparation of fermentation product: Mix plant straw powder and starch with a mass ratio of 4:1, then add fermentation agent and water, wherein the amount of fermentation agent is 0.1% of the total mass of plant straw powder and starch, at 60 ℃ constant temperature fermentation for 40 hours, and then 80 ℃ constant temperature fermentation for 36 hours, after the fermented material is dehydrated by the centrifuge, it enters the dryer for drying, and the inlet temperature of the dryer is controlled at 77-78 ℃, and the outlet temperature is 39-41 ℃ , and then transport the dried material to a cooler for cooling to obtain a fermentation product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com