Biodegradable weeding mulching film, and preparation method thereof

A technology of biodegradation and weeding film, applied in the fields of botanical equipment and methods, weed elimination equipment, plant protection, etc. Improve drug effect time, improve utilization rate and utilization efficiency, and slow down the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

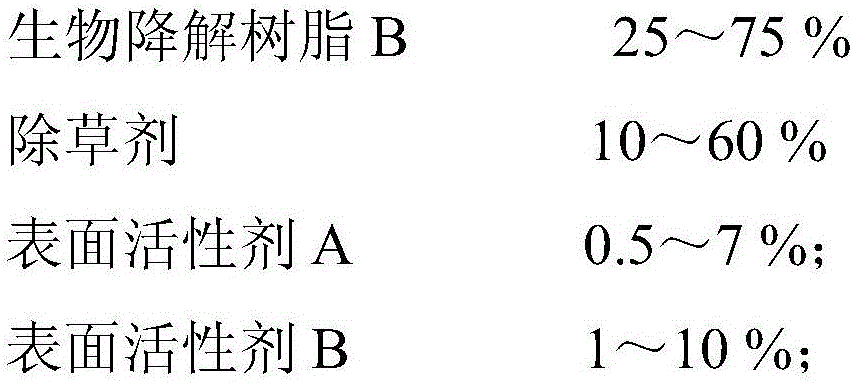

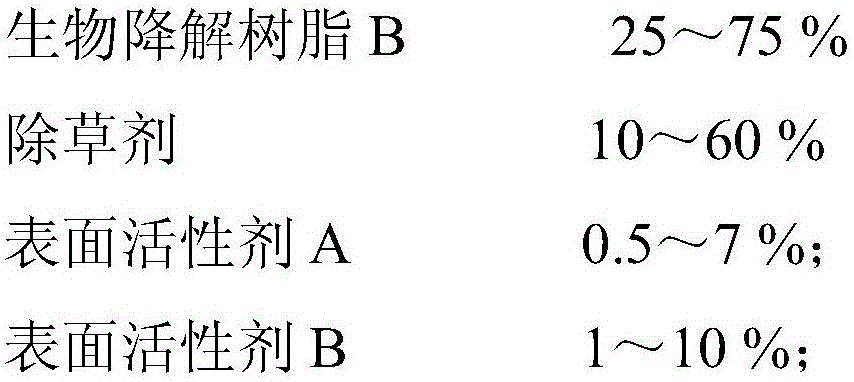

[0049]Preparation of biodegradable herbicide masterbatch:

[0050] Mix atrazine with sorbitan laurate for 3 to 5 minutes, and ultrasonically activate it at 100 to 500 W for 3 to 25 minutes; then mix it with PBAT and glyceryl monostearate, and stir and mix at 600 to 1200 rpm for 1 ~5min, the mixing temperature does not exceed 60°C, extruding and granulating at 110~150°C to obtain the herbicide masterbatch.

[0051] Wherein, the mass percentages of each reactant are: PBAT 75%; atrazine 20%; sorbitan laurate 2.5%; glyceryl monostearate 2.5%.

[0052] Preparation of biodegradable weeding mulch film:

[0053] Mix the biodegradable herbicide masterbatch with PLA and PBAT in a mixer for 3-5 minutes, and blow molding at 130-200°C to obtain a biodegradable herbicide mulch film.

[0054] Wherein, the mass percentage of each reactant is: 30% of biodegradable herbicide masterbatch; 10% of PLA; 60% of PBAT.

[0055] The melt index of PLA used is 3-5g / 10min; the melt index of PBAT used i...

Embodiment 2

[0057] Preparation of biodegradable herbicide masterbatch:

[0058] Mix atrazine with polyoxyethylene lauryl ether for 3 to 5 minutes, ultrasonically activate at 100 to 500 W for 3 to 25 minutes; then mix with PBAT and propylene glycol fatty acid ester, stir and mix at 600 to 1200 rpm for 1 to 5 minutes, and mix The temperature does not exceed 60°C, extruded and granulated at 110-150°C to obtain herbicide masterbatch.

[0059] Wherein, the mass percent of each reactant is: PBAT 75%; atrazine 10%; polyoxyethylene lauryl ether 5%; propylene glycol fatty acid ester 10%.

[0060] Preparation of biodegradable weeding mulch film:

[0061] Mix the biodegradable herbicide masterbatch with PLA and PBAT in a mixer for 3-5 minutes, and blow molding at 130-200°C to obtain a biodegradable herbicide mulch film.

[0062] Wherein, the mass percentage of each reactant is: 10% of biodegradable herbicide masterbatch; 15% of PLA; 75% of PBAT.

[0063] The melt index of PLA used is 3-5g / 10min; ...

Embodiment 3

[0065] Preparation of biodegradable herbicide masterbatch:

[0066] Mix atrazine with polyoxyethylene (4EO) sorbitan monostearate for 3 to 5 minutes, and ultrasonically activate it for 3 to 25 minutes at a power of 100 to 500 W; then mix it with PBAT and propylene glycol monostearate, and Stirring and mixing at 600-1200 rpm for 1-5 minutes, the mixing temperature does not exceed 60°C, extruding and granulating at 110-150°C to obtain the herbicide masterbatch.

[0067] Wherein, the mass percent of each reactant is: PBAT 30%; atrazine 60%; polyoxyethylene (4EO) sorbitan monostearate 5%; propylene glycol monostearate 5%.

[0068] Preparation of biodegradable weeding mulch film:

[0069] Mix the biodegradable herbicide masterbatch with PLA and PBAT in a mixer for 3-5 minutes, and blow molding at 130-200°C to obtain a biodegradable herbicide mulch film.

[0070] Wherein, the mass percentage of each reactant is: 3% of biodegradable herbicide masterbatch; 20% of PLA; 77% of PBAT. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com