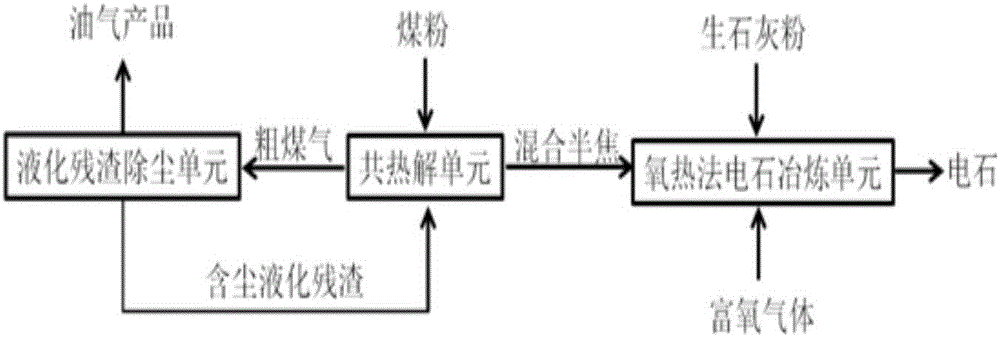

System and method for pulverized coal pyrolysis coupling calcium carbide production

A technology of calcium carbide and coal powder, which is applied in the system field of coal powder pyrolysis coupled with calcium carbide production, can solve the problems of high dust content in oil and gas products, decline in lump coal output, waste of solid coal powder or semi-coke, etc., to reduce raw material costs and Production energy consumption, reducing energy consumption and raw material costs, and promoting the effect of catalytic cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

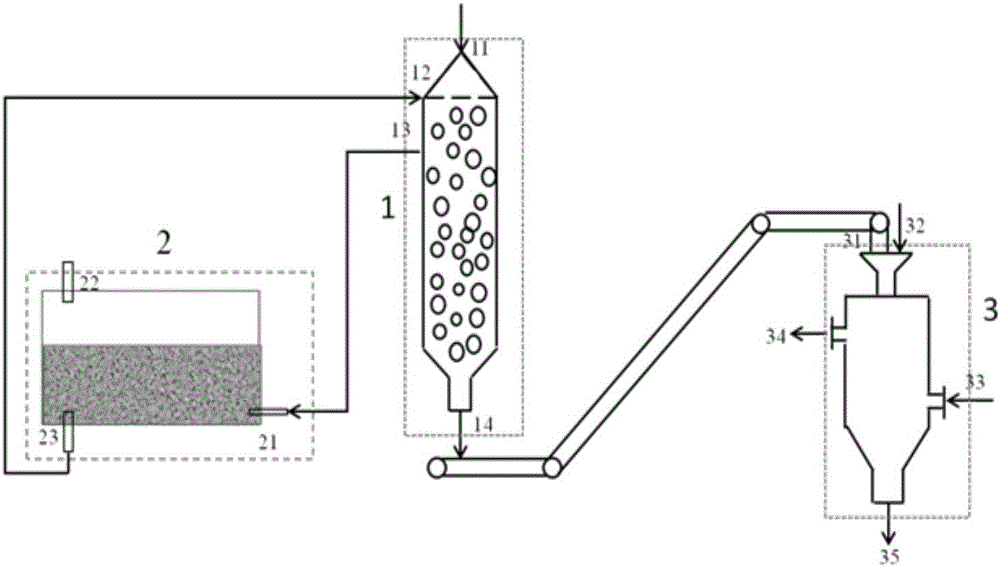

Embodiment 1

[0061] Using the system of the present invention, the pulverized coal with a particle size of less than 6mm and the liquefied residue at 280°C from the liquefied residue dedusting unit are sprayed into the fast pyrolysis furnace respectively, and the mass ratio of the pulverized coal to the liquefied residue reacted is 1 :0.4, the mixed material relies on the effect of gravity to pass through the low-temperature dry distillation section and the high-temperature dry distillation section of the fast pyrolysis furnace successively; wherein, the temperature of the low-temperature dry distillation section is 550-600°C, and the temperature of the high-temperature dry distillation section is 870-900°C; In the dry distillation section, the liquefied residue is basically completely pyrolyzed, while the coal powder undergoes mild pyrolysis in this section, and the products are mainly pyrolysis gas and light tar; in the high-temperature dry distillation section, the coal powder pyrolyzes c...

Embodiment 2

[0064] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. Using the system of the present invention, the pulverized coal with a particle size of less than 6mm and the liquefied residue at 360°C from the liquefied residue dedusting unit are sprayed into the fast pyrolysis furnace respectively, and the mass ratio of the pulverized coal to the liquefied residue reacted is 1 :0.5, the mixed material relies on the effect of gravity to pass through the low-temperature dry distillation section and the high-temperature dry distillation section of the fast pyrolysis furnace successively; wherein, the temperature of the low-temperature dry distillation section is 580-620°C, and the temperature of the high-temperature dry distillation section is 850-880°C; In the dry distillation section, the liquefied residue is basically completely pyrolyzed, while the coal powder undergoes mild pyrolysis in t...

Embodiment 3

[0067] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. Using the system of the present invention, the pulverized coal with a particle size of less than 6mm and the liquefied residue at 320°C from the liquefied residue dedusting unit are sprayed into the fast pyrolysis furnace respectively, and the mass ratio of the pulverized coal to the liquefied residue reacted is 1 :0.3, the mixed material relies on the effect of gravity to pass through the low-temperature dry distillation section and the high-temperature dry distillation section of the fast pyrolysis furnace successively; wherein, the temperature of the low-temperature dry distillation section is 650-700°C, and the temperature of the high-temperature dry distillation section is 920-950°C; In the dry distillation section, the liquefied residue is basically completely pyrolyzed, while the coal powder undergoes mild pyrolysis in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com