Double-face leather integrated dyeing technology for lambskin

A technology of lambskin and fur leather, which is applied in the field of integrated dyeing technology of lambskin and fur leather, can solve problems such as environmental pollution, reduce production costs, improve product benefits, and solve the effects of easy dew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

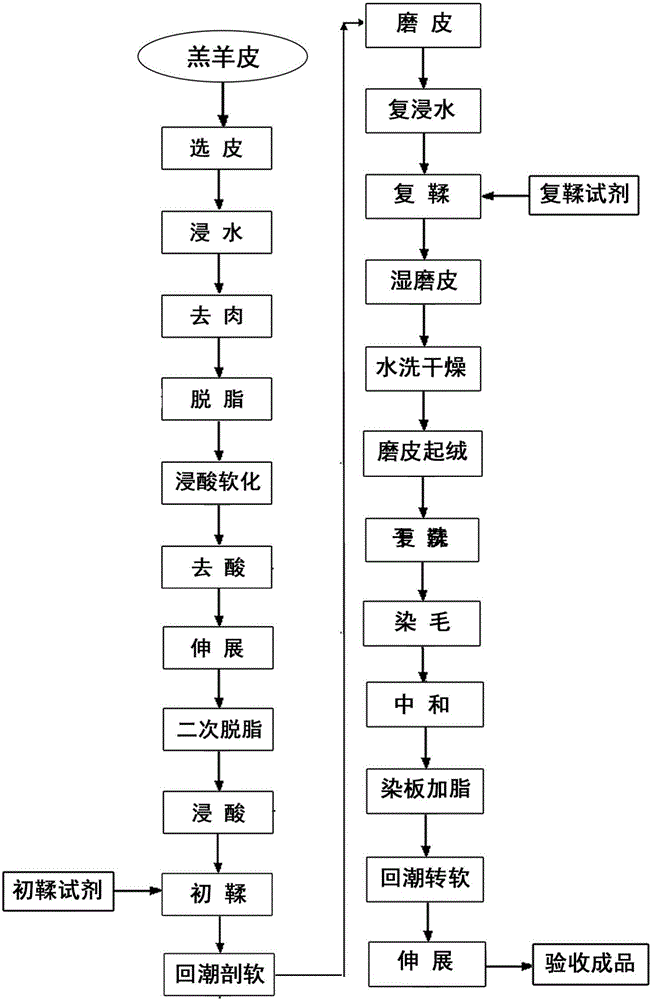

Image

Examples

Embodiment 1

[0041] Material: Goat lamb leather

[0042] The integral dyeing process of lamb wool leather includes the following steps:

[0043] S1: Leather selection: choose lambskin boards with no damage to raw hides as raw materials for wool leather;

[0044] S2: Soaking in water: mix the leather raw material with water at a ratio of 1:10 at room temperature, add 0.3g / L fresh-recovering agent and soak for 24 hours;

[0045] S3: Meat removal: use a meat remover to remove the meat and oil on the leather board after soaking in water;

[0046] S4: Degreasing: Adding 3-5 g / L degreasing agent to degreasing for 1-2 hours at a temperature of 45°C-50°C at a ratio of 1:20 to the fur raw material after fleshing treatment and water;

[0047] S5: Pickling and softening: Add 3-5ml / L formic acid and 3-4ml / L sulfuric acid to the degreased wool leather raw material and water at a ratio of 1:20 at a temperature of 35°C-40°C , 40-60g / L salt, 1-2g / L fur softener for pickling and softening for 48-60h;

...

Embodiment 2

[0068] Raw material: Tan lamb leather

[0069] The integral dyeing process of lamb wool leather includes the following steps:

[0070] S1: Leather selection: choose lambskin boards with no damage to raw hides as raw materials for wool leather;

[0071] S2: Soaking in water: mix the leather raw material with water at a ratio of 1:10 at room temperature, add 0.3g / L fresh-recovering agent and soak for 24 hours;

[0072] S3: Meat removal: use a meat remover to remove the meat and oil on the leather board after soaking in water;

[0073] S4: Degreasing: Adding 3-5 g / L degreasing agent to degreasing for 1-2 hours at a temperature of 45°C-50°C at a ratio of 1:20 to the fur raw material after fleshing treatment and water;

[0074] S5: Pickling and softening: Add 3-5ml / L formic acid and 3-4ml / L sulfuric acid to the degreased wool leather raw material and water at a ratio of 1:20 at a temperature of 35°C-40°C , 40-60g / L salt, 1-2g / L fur softener for pickling and softening for 48-60h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com