High-strength and medium-conductivity novel copper alloy Cu-Zn-Cr-RE conducting bar and preparation method

A technology of copper alloy and master alloy, which is applied in the field of motor rotor material manufacturing, can solve problems such as poor high-temperature strength, achieve high tensile strength, refine grain size, and improve high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

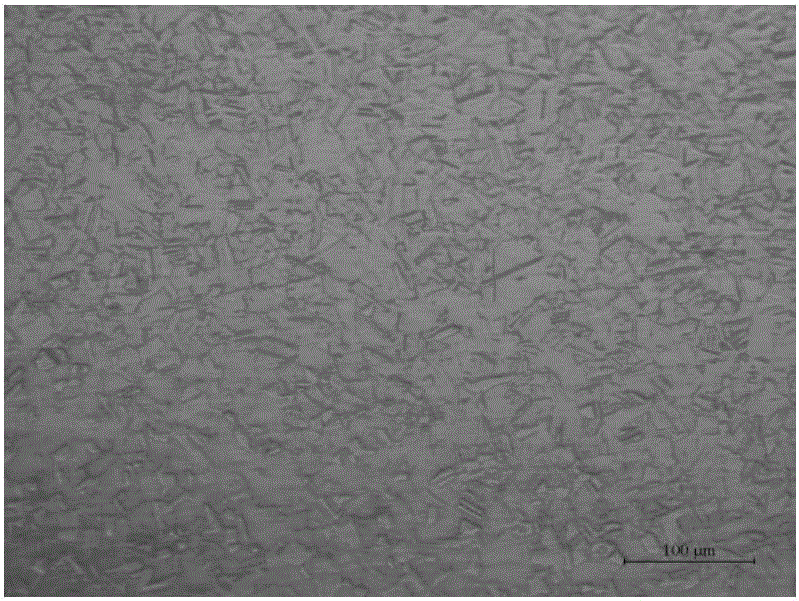

Embodiment 1

[0026] A high-strength, medium-conductivity new copper alloy Cu-10Zn-0.25Cr-0.08RE guide bar and its preparation method are characterized in that it includes the following steps:

[0027] (1) Ingredients: Proportion each alloy element according to the composition and ratio requirements, select and weigh the corresponding raw materials; Cu is added by copper plate, Zn is added by zinc ingot, and Cr is added by Cu-Cr intermediate alloy The RE is added in the form of La-Ce master alloy; wherein, the copper plate is an electrolytic copper plate with a purity greater than 99%. Wherein, the zinc ingot is commercially available No. 2 zinc with a purity greater than 99.95%.

[0028] (2) Melting: Melting in a non-vacuum intermediate frequency induction furnace. After the copper plate and Cu-Cr master alloy are melted, add zinc ingots, and then add La-Ce master alloy. After the smelting is completed, pour into ingots and cool to room temperature. Among them, the Cu-Cr master alloy is m...

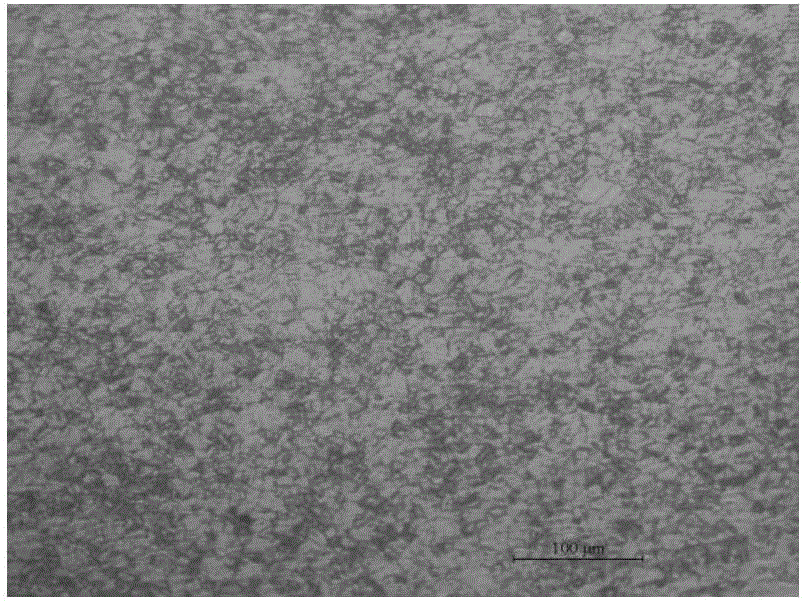

Embodiment 2

[0032] A high-strength, medium-conductivity new copper alloy Cu-6Zn-0.3Cr-0.06RE guide bar and its preparation method are characterized in that it comprises the following steps:

[0033] (1) Ingredients: Proportion each alloy element according to the composition and ratio requirements, select and weigh the corresponding raw materials; Cu is added by copper plate, Zn is added by zinc ingot, and Cr is added by Cu-Cr intermediate alloy The RE is added in the form of La-Ce master alloy; wherein, the copper plate is an electrolytic copper plate with a purity greater than 99%. Wherein, the zinc ingot is commercially available No. 2 zinc with a purity greater than 99.95%.

[0034] (2) Melting: Melting in a non-vacuum intermediate frequency induction furnace. After the copper plate and Cu-Cr master alloy are melted, add zinc ingots, and then add La-Ce master alloy. After the smelting is completed, pour into ingots and cool to room temperature. Among them, the electrolytic copper plat...

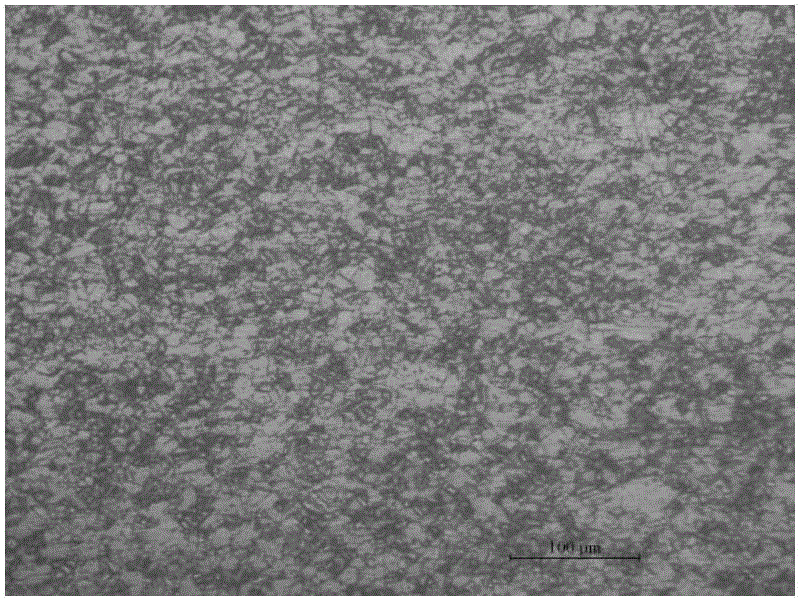

Embodiment 3

[0038] A high-strength, medium-conductivity new copper alloy Cu-8Zn-0.3Cr-0.1RE guide bar and its preparation method are characterized in that it comprises the following steps:

[0039] (1) Ingredients: Proportion each alloy element according to the composition and ratio requirements, select and weigh the corresponding raw materials; Cu is added by copper plate, Zn is added by zinc ingot, and Cr is added by Cu-Cr intermediate alloy The RE is added in the form of La-Ce master alloy; wherein, the copper plate is an electrolytic copper plate with a purity greater than 99%. Wherein, the zinc ingot is commercially available No. 2 zinc with a purity greater than 99.95%.

[0040] (2) Melting: Melting in a non-vacuum intermediate frequency induction furnace. After the copper plate and Cu-Cr master alloy are melted, add zinc ingots, and then add La-Ce master alloy. After the smelting is completed, pour into ingots and cool to room temperature. Among them, the electrolytic copper plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com